Free PLC course outline

- Lesson #1: What Is It and Why Should Every PLC Programmer Know It? Part #1

- Lesson #2: How to install Codesys? Part #2

- Lesson #3: Write your first program in Codesys: Structured Text – Part #3

- Lesson #4: How to Create a Codesys Visualization in an Application? – Part #4

- Lesson #5: Introduction to Variables in CODESYS – Part #5

- Lesson #6: Data Structures in CODESYS: Practical Use of Arrays and Structures – Part #6

- Lesson #7: Advanced Data Types. Enumerations and Local vs. Global Variables – Part #7

- Lesson #8: Operators – Introduction and Practical Applications – Part #8

- Lesson #9: Program Flow Control: IF, CASE, and Loops – Part #9

CODESYS

In today’s world, not keeping up with technological advancements can lead to being excluded from the industry within 2–3 years. Every automation engineer should stay current with all new systems entering the market!

With a thorough understanding of the market, you can offer your clients the optimal solution in terms of functionality and price, giving you an edge over competitors who have been using the same system for 15 years without any updates.

One system that can give you a competitive edge in automation is Codesys!

What is Codesys? In a few words…

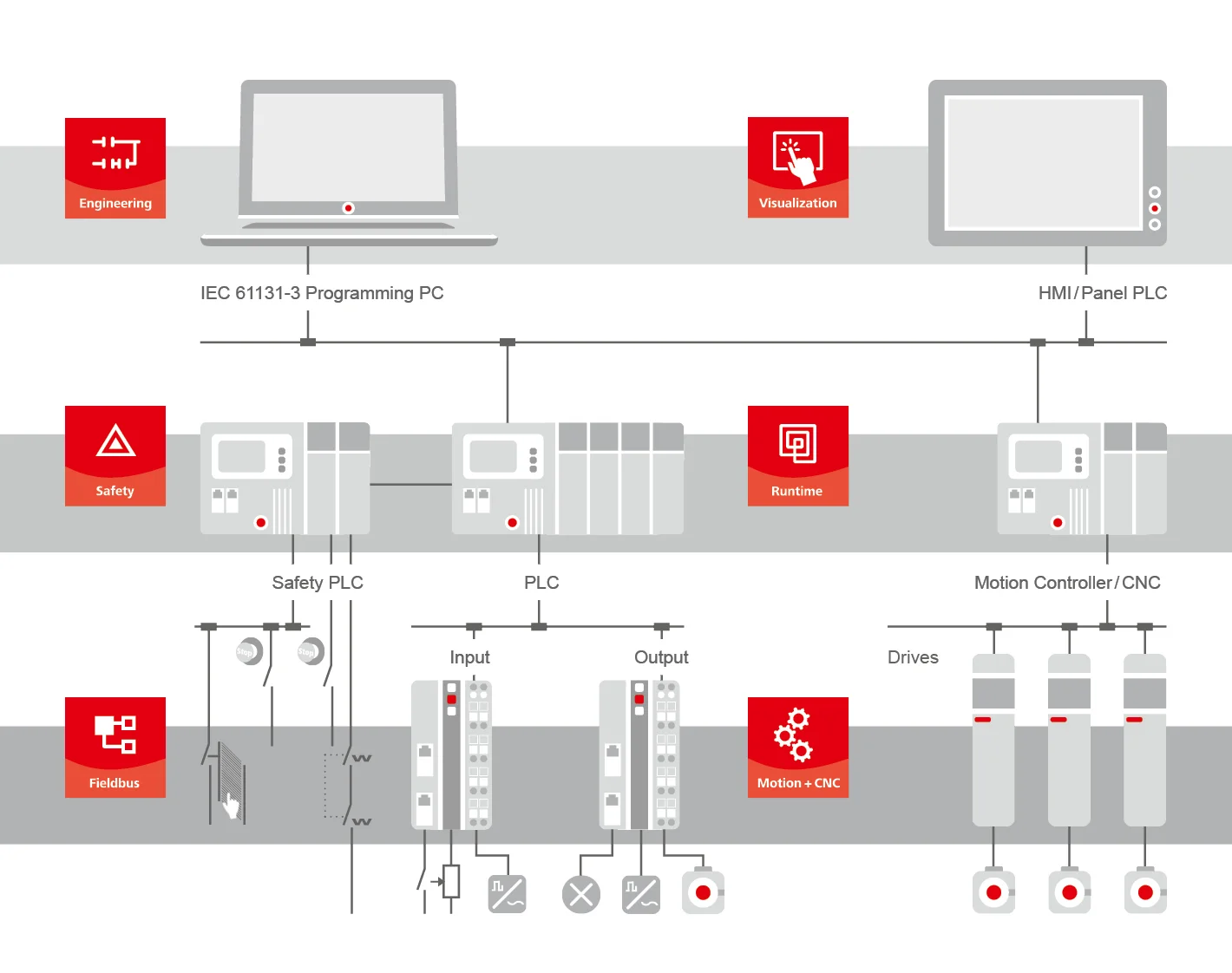

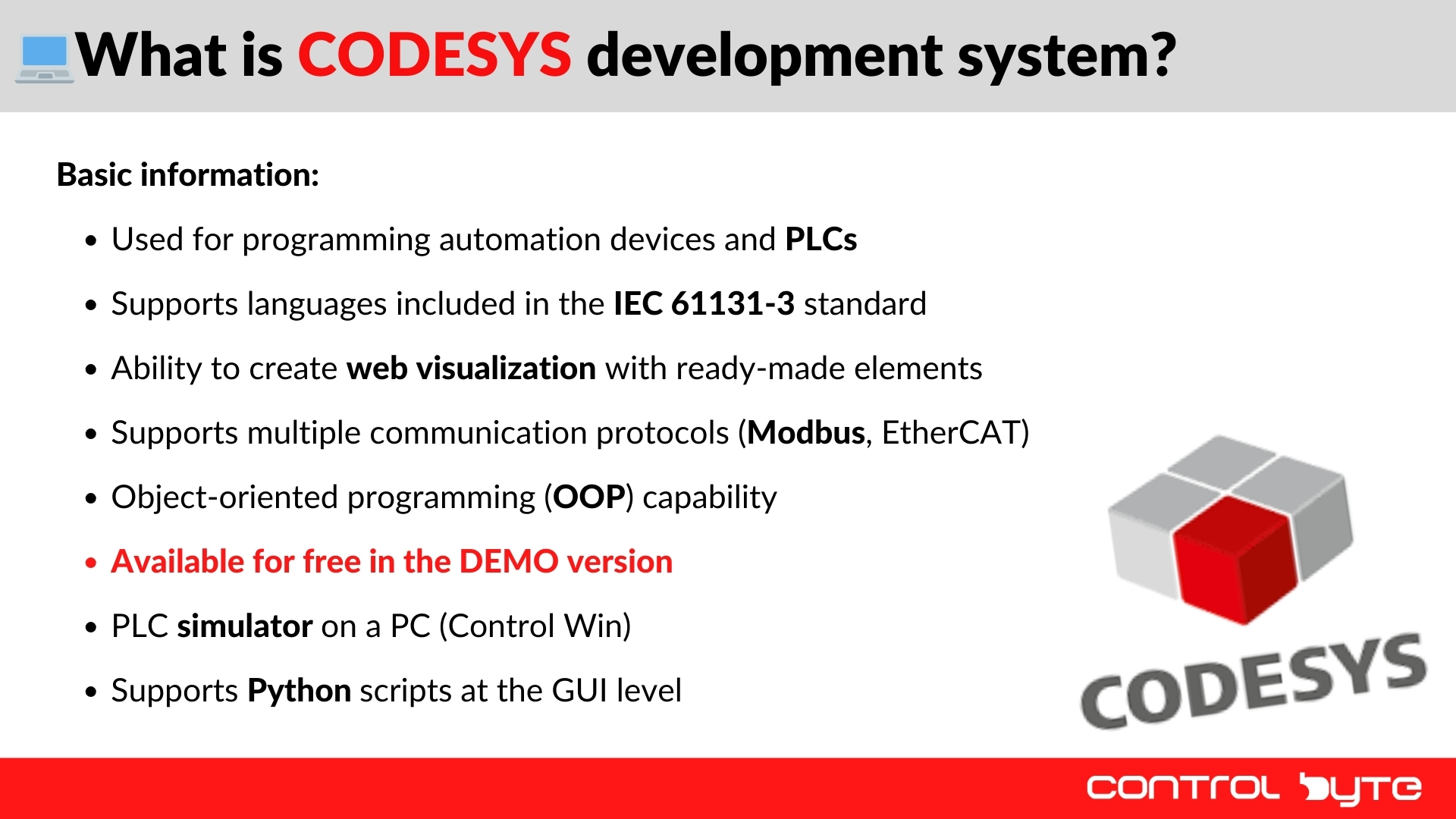

CODESYS is advanced software for programming PLCs (Programmable Logic Controllers), developed by 3S-Smart Software. It’s a comprehensive environment that includes both the development environment (IDE – Integrated Development Environment) and the runtime environment.

The CODESYS IDE provides developers with intuitive and efficient tools to create control applications. It offers a variety of functions, such as a code editor, debugger, user interface design tools, and more, allowing developers to easily design, test, and enhance their applications.

The CODESYS Runtime is the runtime environment installed on PLCs, where applications created in the CODESYS IDE are executed. The Runtime is responsible for interpreting and executing control code and ensuring communication with other devices in the system.

Why has Codesys become so popular in recent years?

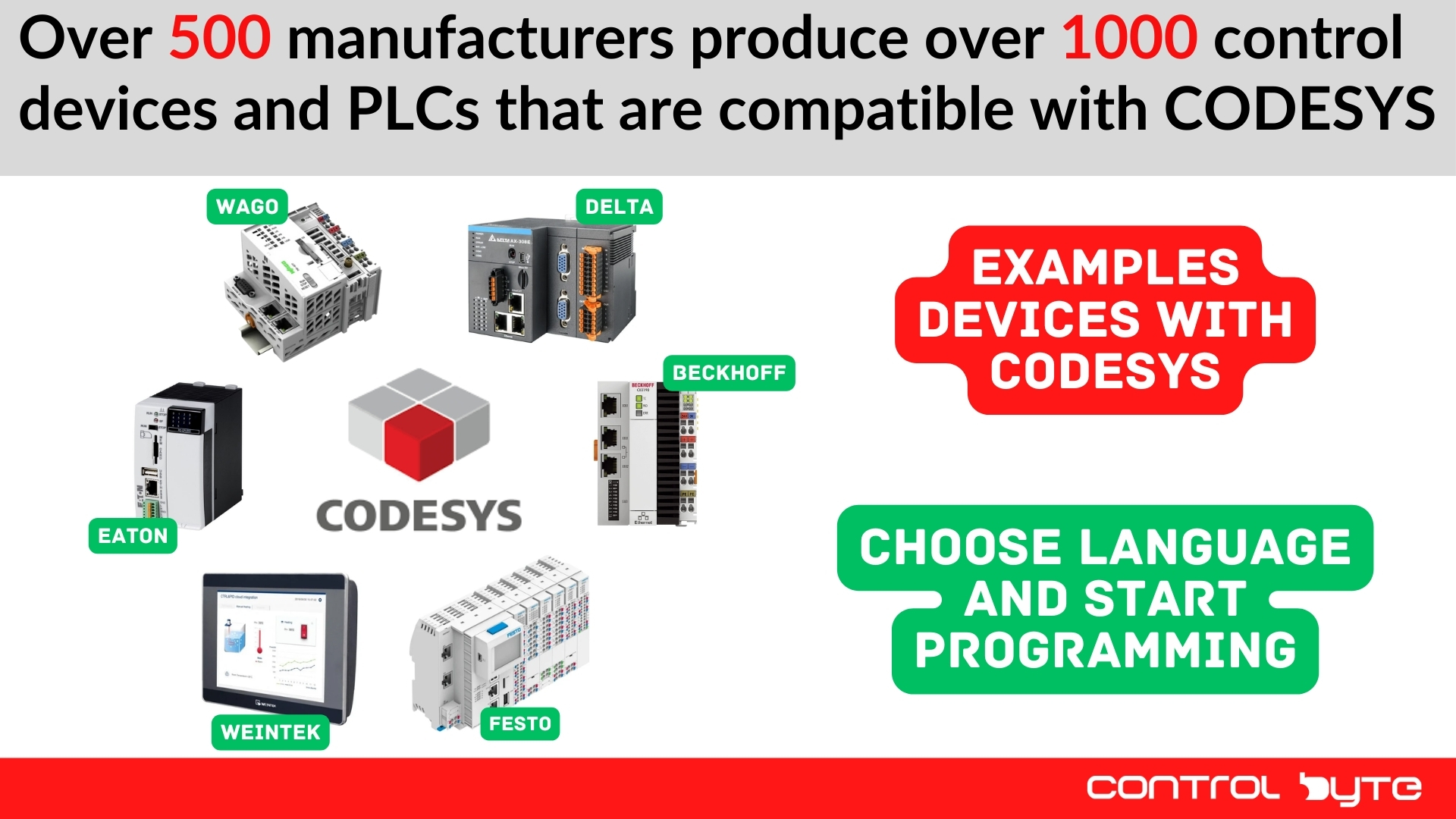

CODESYS has become a popular software solution adopted by many PLC manufacturers. Here are a few examples of such companies:

- Phoenix Contact

- Eaton

- Festo

- Lenze

- Delta

- Weintek

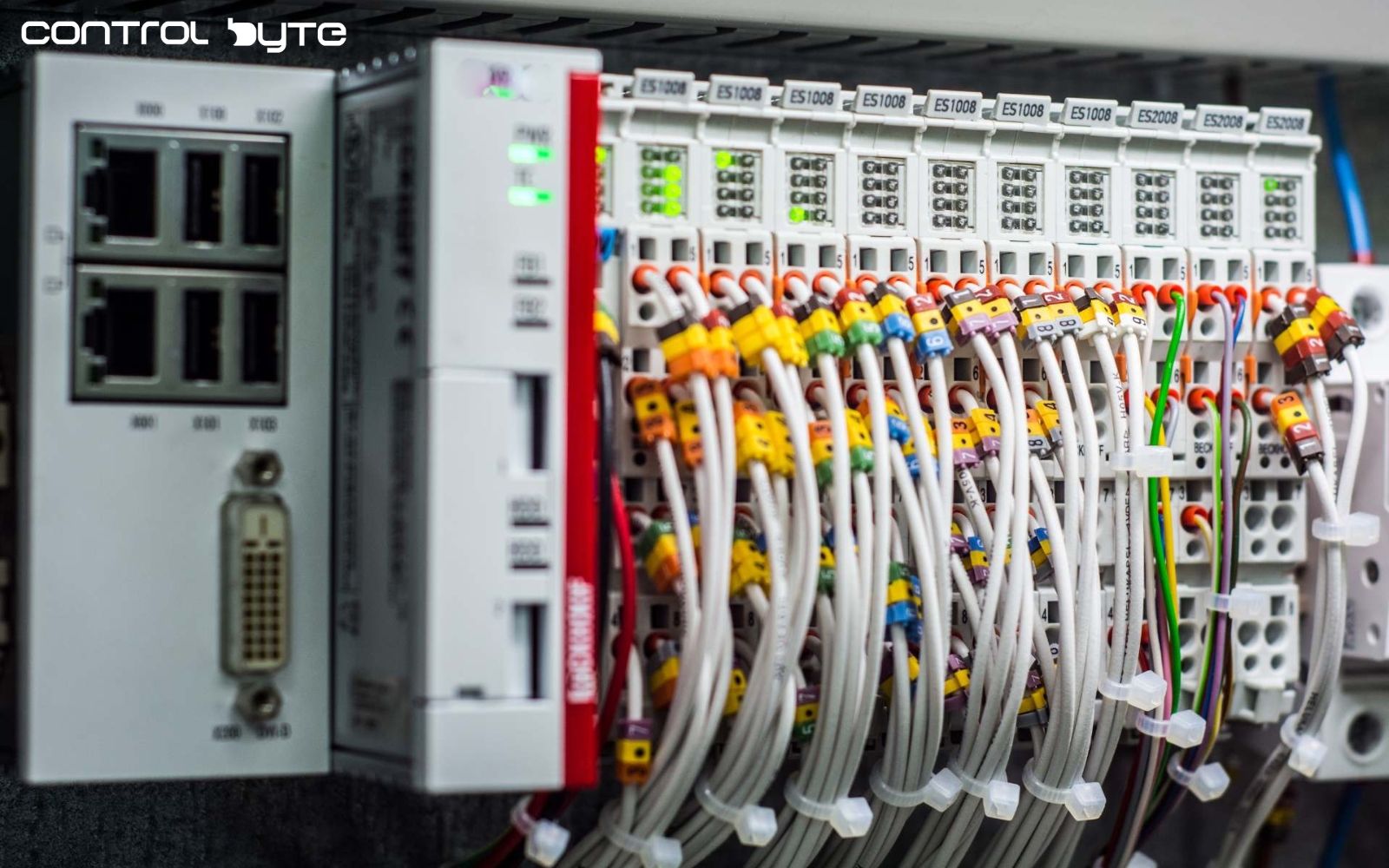

- Beckhoff Automation

- WAGO Kontakttechnik

- Bosch Rexroth

- Turck

- and many more…

You can find the full list here: CODESYS Partners

Why have global automation manufacturers chosen to produce PLCs based on Codesys?

Siemens introduced its first PLCs in the 1970s, revolutionizing industrial control and automation. Over the years, they have continued to develop their platform and hardware.

Many companies aspire to join the ranks of PLC manufacturers by offering this equipment; however, it’s not an easy task! As a result, they have chosen to utilize Codesys as the programming platform and Runtime for their products, which allows them to save nearly 15 years they would otherwise spend developing their own platform and software from scratch.

CODESYS: A flexible programming approach

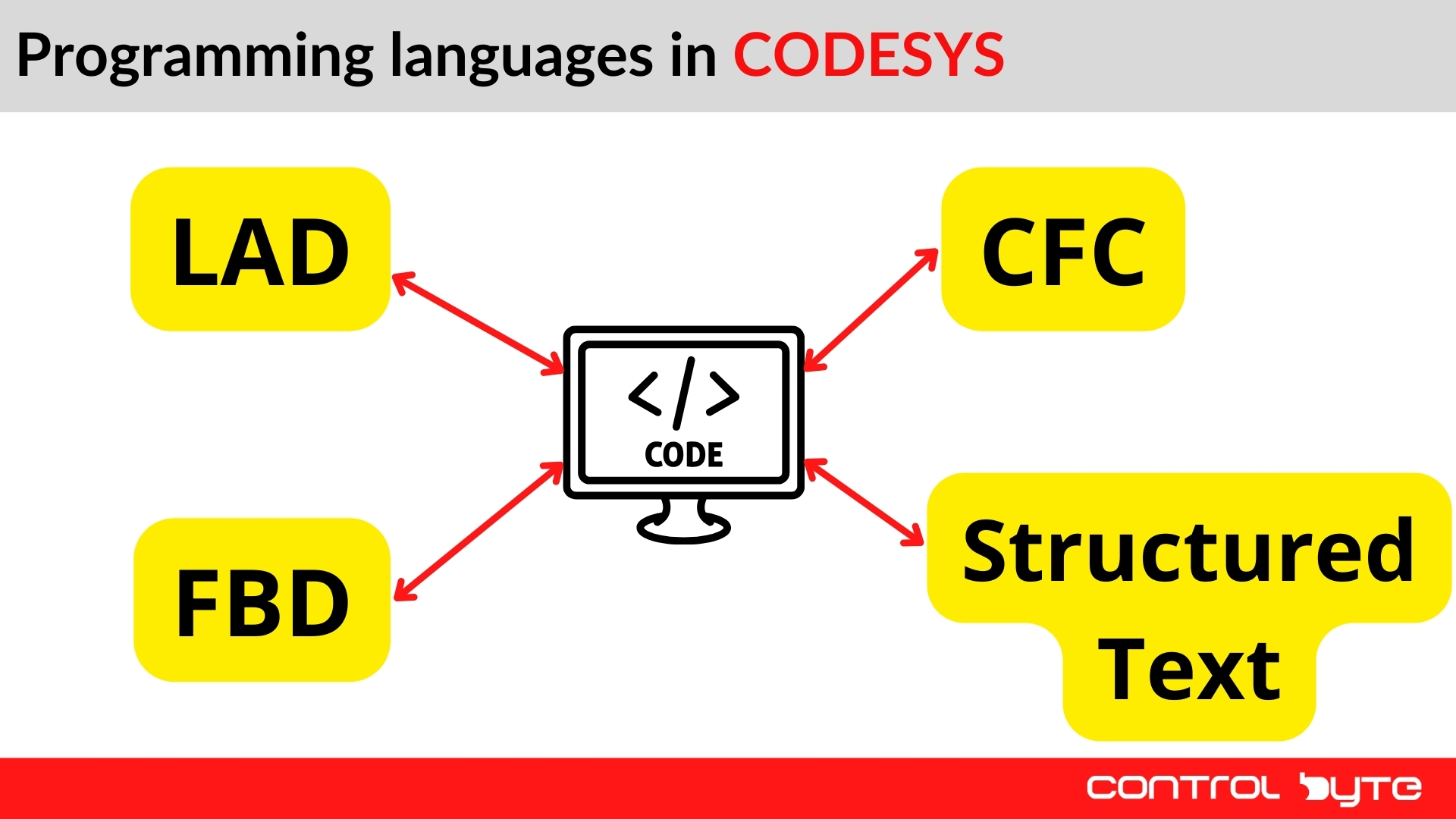

CODESYS supports various programming languages, such as:

- Ladder Diagram (LD) (IEC 61131-3 standard)

- Structured Text (ST) (IEC 61131-3 standard)

- Function Block Diagram (FBD) (IEC 61131-3 standard)

- Instruction List (IL) (IEC 61131-3 standard)

- Sequential Function Chart (SFC) (IEC 61131-3 standard)

- C/C++

- Python

Its openness to different programming languages offers developers greater flexibility, allowing them to use preferred tools and techniques.

Transcript of Codesys in Different Automation Systems

Here’s a closer look at some automation equipment manufacturers that have equipped their PLCs with Codesys Runtime or have created software overlays closely based on software provided by 3S-Smart Software.

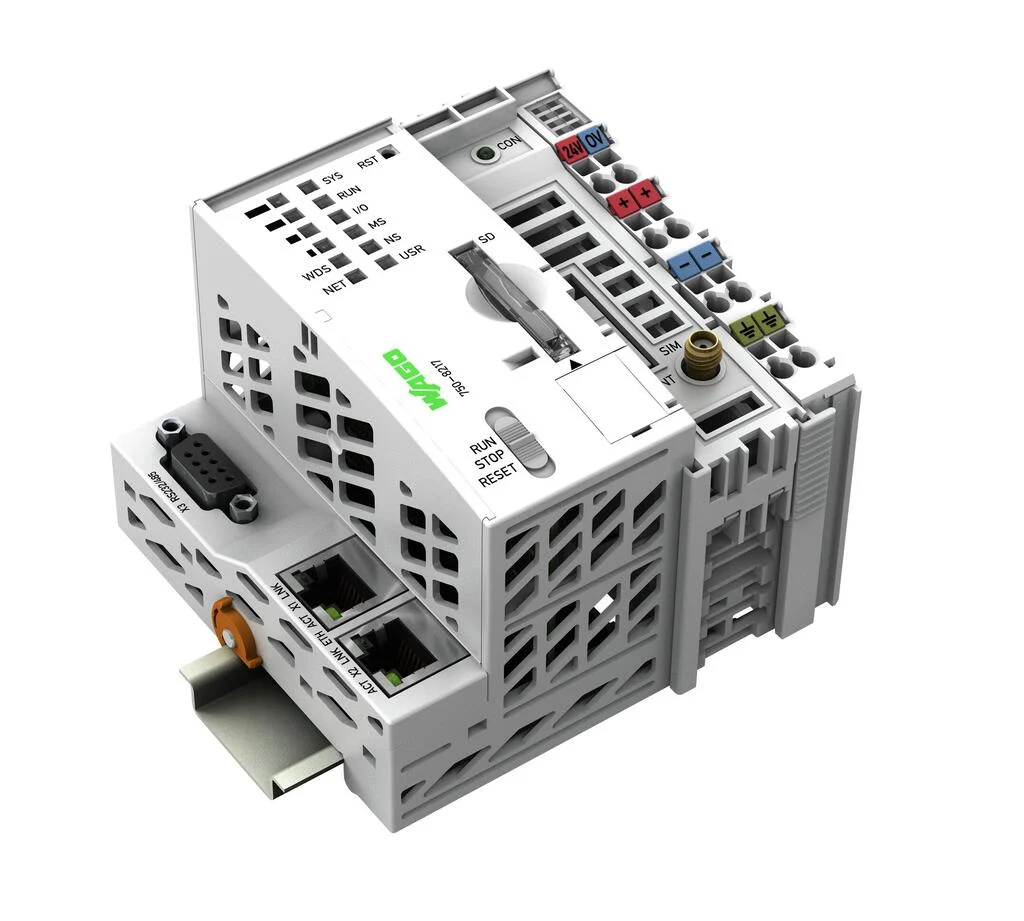

WAGO, Beckhoff – Building Automation

Beckhoff and WAGO PLCs are commonly used in building automation, offering extensive control over HVAC systems, lighting, security, and other aspects of building infrastructure. Both brands are recognized leaders in this field, providing reliable solutions for building automation.

Lenze – Motion Controllers in Industrial Automation

Lenze, a well-known company in industrial automation and electric drives, has been delivering innovative solutions across various industries for over 70 years. Its offerings include motors, inverters, gearboxes, and controllers. Recently, Lenze introduced high-performance motion controllers, programmable through PLC Designer, an overlay on the CODESYS environment.

Delta – Motion Controllers

Delta’s AX-300 series motion processor uses the CODESYS platform, supporting motion and logic control applications. It comes equipped with multiple communication ports and EtherCAT motion control interface, and offers international standard-compliant motion control function blocks, which have applications across wood, packaging, printing, labeling, textile, and pharmaceutical industries.

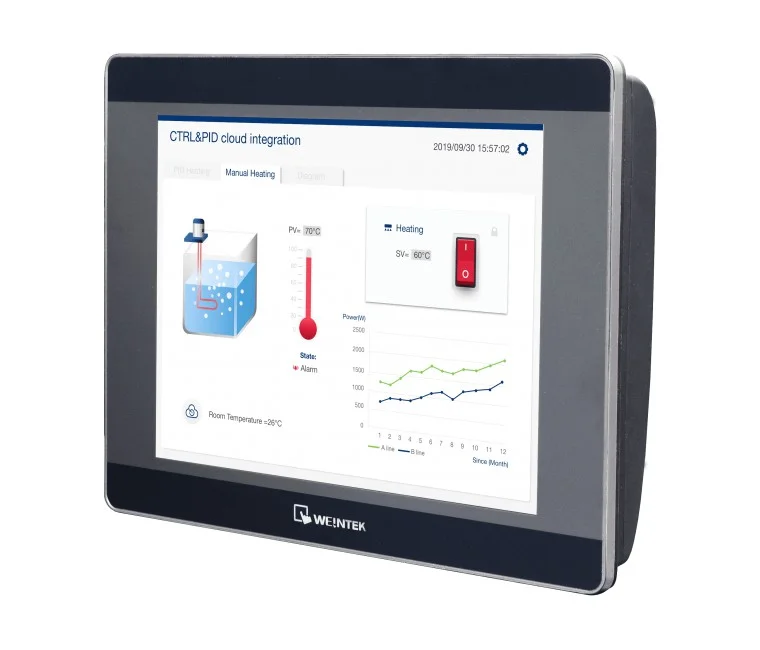

Weintek – HMI Panels with Built-in CODESYS PLC

The Weintek cMT3092X panel integrates a powerful HMI panel and a CODESYS-programmable PLC, compliant with the IEC 61131-3 standard. This combination offers a unified and flexible application architecture.

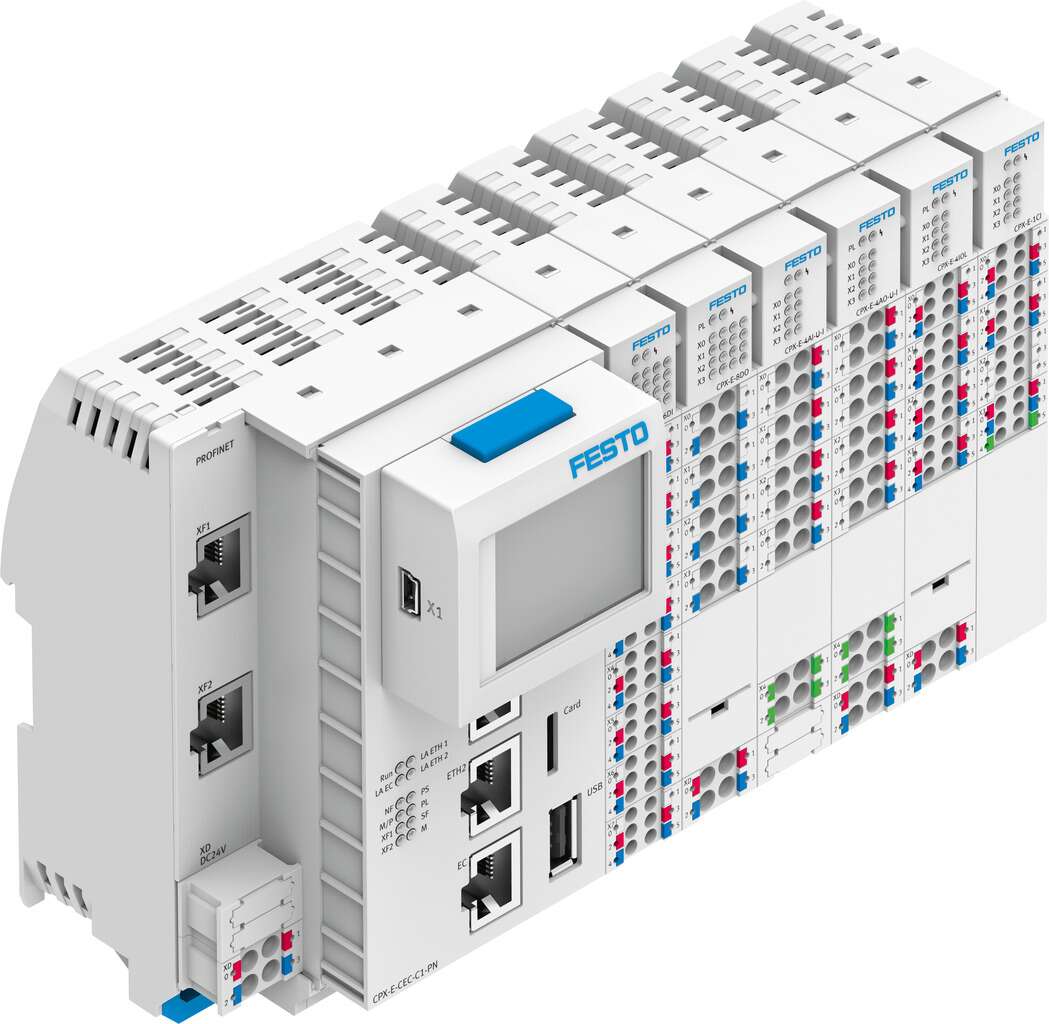

Festo – Not Only Pneumatics

The Festo CPX-E is designed for use as a master controller and EtherCAT motion controller, providing a compact, cost-effective solution. It allows modern programming using CoDeSys V3 according to the IEC 61131-3 standard and supports SoftMotion libraries.

EATON

The modular XC100 and XC200 controllers from EATON are known for their scalability. The compact XC152 controllers, with high computational power and connectivity options, enable cost-effective solutions in automation.

Schneider Electric

Engineers can program Schneider Electric’s Modicon M251 controllers using the EcoStruxure Machine Expert environment, an interface built on top of Codesys. Widely adopted by major corporations, Schneider Electric PLCs are essential in various critical applications. For instance, they play a key role in controlling runway lighting systems at airports.

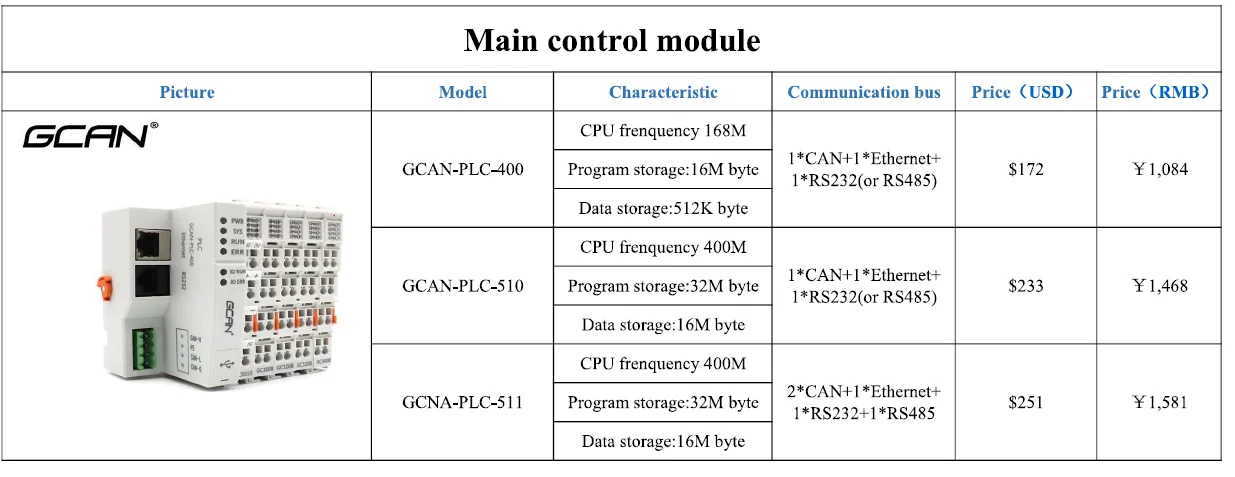

Interesting Find – GCAN – A Budget PLC for the Chinese Market

GCAN is a Chinese PLC manufacturer that has been in operation since 2012, offering modular PLC CPUs equipped with CODESYS Runtime software.

Summary

Today, to stay competitive in the automation industry, you need to keep up with the latest technological advancements. It’s crucial to track developments in the field of automation, and one tool that can give you a market advantage is CODESYS.

Thanks to this advanced development environment, you’ll be able to create efficient control applications tailored to your clients’ needs. Many renowned PLC manufacturers use CODESYS, which demonstrates its popularity and versatility. Knowledge and proficiency with CODESYS open up numerous opportunities in the automation industry, allowing you to deliver innovative solutions and meet the demands of a rapidly evolving market.

Free PLC course outline

- Lesson #1: What Is It and Why Should Every PLC Programmer Know It? Part #1

- Lesson #2: How to install Codesys? Part #2

- Lesson #3: Write your first program in Codesys: Structured Text – Part #3

- Lesson #4: How to Create a Codesys Visualization in an Application? – Part #4

- Lesson #5: Introduction to Variables in CODESYS – Part #5

- Lesson #6: Data Structures in CODESYS: Practical Use of Arrays and Structures – Part #6

- Lesson #7: Advanced Data Types. Enumerations and Local vs. Global Variables – Part #7

- Lesson #8: Operators – Introduction and Practical Applications – Part #8

- Lesson #9: Program Flow Control: IF, CASE, and Loops – Part #9