Human-Machine Interface (HMI)

The Human-Machine Interface (HMI) plays a pivotal role in modern industrial automation, facilitating communication between operators and machines while providing easy access to process information. Over the years, HMI systems have evolved significantly—from simple control panels to sophisticated touchscreens featuring advanced graphics and integration with other systems. This guide delves into what HMI is, the components that enable its functionality, and the best practices for designing and programming such interfaces.

Definition and Importance of HMI

HMI (Human-Machine Interface) refers to systems designed to facilitate communication between humans and machines in industrial environments. These interfaces provide users with seamless access to process data and allow them to control various operations. Modern HMIs are employed in factories, power plants, HVAC systems, and many other industries, enabling operators to monitor process parameters, adjust settings, and respond to emergencies effectively.

HMI serves as a bridge between the human and machine worlds. Practically speaking, it grants access to the entire control system—from machine parameters to alarms, performance statistics, and much more. Operators gain full control over processes, enabling real-time decision-making and ensuring efficient operations.

Evolution of HMI Systems

Initially, HMI systems were very basic—mainly consisting of panels with buttons, switches, and indicator lights. Operators used these panels to start and stop machines, while signal lights provided information about system status. As technology advanced, the first text displays emerged, enabling the presentation of basic process information.

Over time, graphical displays became the standard. Modern HMI systems now feature high-resolution, touch-sensitive, full-color screens capable of displaying complex graphics and charts. The next significant milestone in HMI evolution was their integration with SCADA and ERP systems, making process management and data access seamless across the entire organization.

Key Components of HMI Systems

An HMI system is composed of three essential elements: hardware, software, and communication protocols.

Hardware

The hardware forms the physical layer of the interface. This includes operator panels, industrial computers, or dedicated tablets designed to withstand harsh industrial conditions, such as vibrations, high humidity, or extreme temperatures. HMI hardware must ensure reliability and longevity to maintain seamless operations in challenging environments.

Software

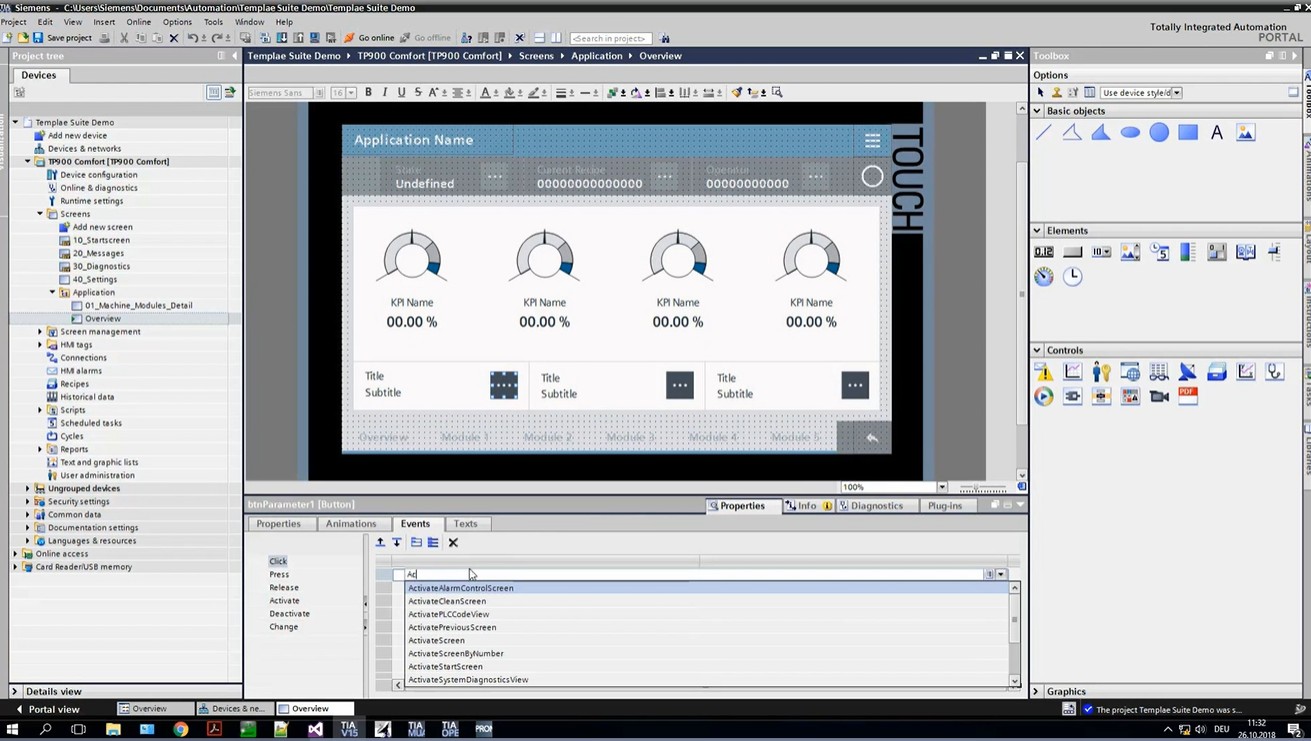

Software is the soul of an HMI system. It defines how operators interact with machines. Various platforms are used to design interfaces that must be intuitive and user-friendly. Examples of such tools include Wonderware, Siemens WinCC, and Rockwell FactoryTalk.

FactoryTalk View Studio Machine Edition (ME)

FactoryTalk View Studio Machine Edition (ME) is one of the most versatile tools for creating HMI applications, offered by Rockwell Automation. Widely used in industrial environments, this platform enables the design of HMI screens tailored for integration with automation systems. ME supports features such as real-time process monitoring, alarm handling, and data visualization. It is particularly well-suited for developing solutions for PanelView Plus, one of the most popular devices used in industrial facilities.

FactoryTalk View Studio ME allows users to quickly design and deploy applications, significantly accelerating the implementation of new solutions in a factory setting. Its intuitive user interface and pre-configured components simplify development, even for less experienced users. Thanks to the HMI Tag Database feature, ME offers convenient management of all system variables, enhancing application clarity and facilitating future modifications.

TP1500 COMFORT

MPN: 6AV2124-0QC02-0AX0

Brand: Siemens

Price: €4 784,00

TP700 Comfort Panel

MPN: 6AV2124-0GC01-0AX0

Brand: Siemens

Price: €579,00

TP900 WIN/CE OPERATOR PANEL

MPN: 6AV2124-0JC01-0AX0

Brand: Siemens

Price: €1 529,10

TP1200 COMFORT PANEL

MPN: 6AV2124-0MC01-0AX0

Brand: Siemens

Price: €1 593,75

SIMATIC HMI TP2200 COMFORT

MPN: 6AV2124-0XC02-0AX1

Brand: Siemens

Price: €2 750,00

KTP400 Comfort

MPN: 6AV2124-2DC01-0AX0

Brand: Siemens

Price: €415,00

SIMATIC HMI TP1900 COMFORT

MPN: 6AV2124-0UC02-0AX1

Brand: Siemens

Price: €2 499,00

SIMATIC KTP600 Basic Color

MPN: 6AV6647-0AC11-3AX0

Brand: Siemens

Price: €930,00

SIMATIC BASIC COLOR PANEL KT 10 TFT

MPN: 6AV6647-0AF11-3AX0

Brand: Siemens

Price: €2 576,00

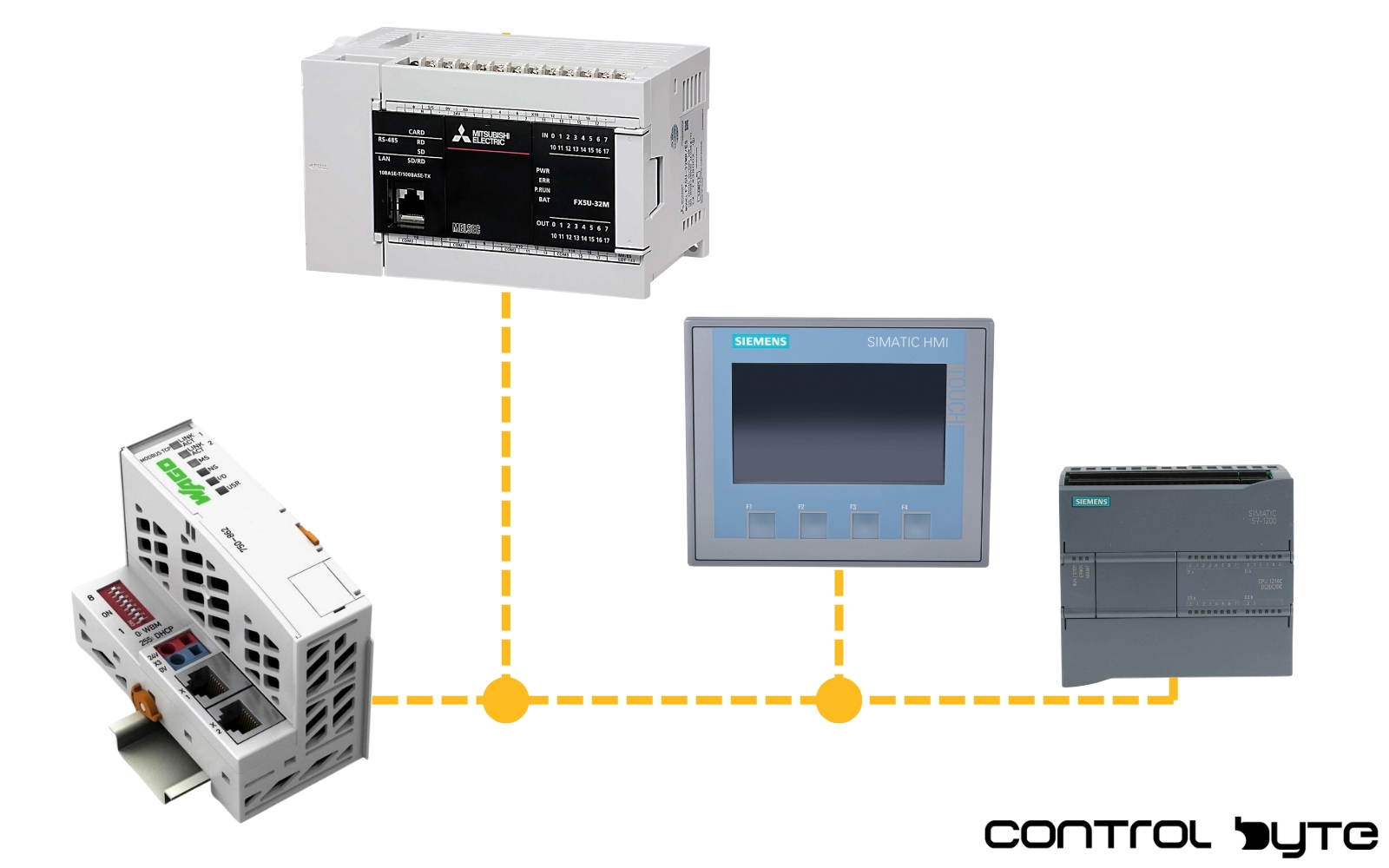

Communication Protocols

Communication protocols are essential for exchanging information between the HMI and control systems, such as PLCs or sensors. Modern HMI systems support a wide range of protocols, including Modbus, Ethernet/IP, Profibus, Profinet, and OPC UA, ensuring versatility and seamless integration with various types of devices.

The Process of Designing and Programming HMI

Creating an effective HMI system is a complex process that requires consideration of both technical and ergonomic aspects. This process can be divided into several key stages:

1. User Requirements Analysis

The first step in HMI design is understanding the needs of the operator and the requirements of the specific process. Engineers must analyze the application’s specifications, determine which information is critical for the operator, and identify the most frequently used functions.

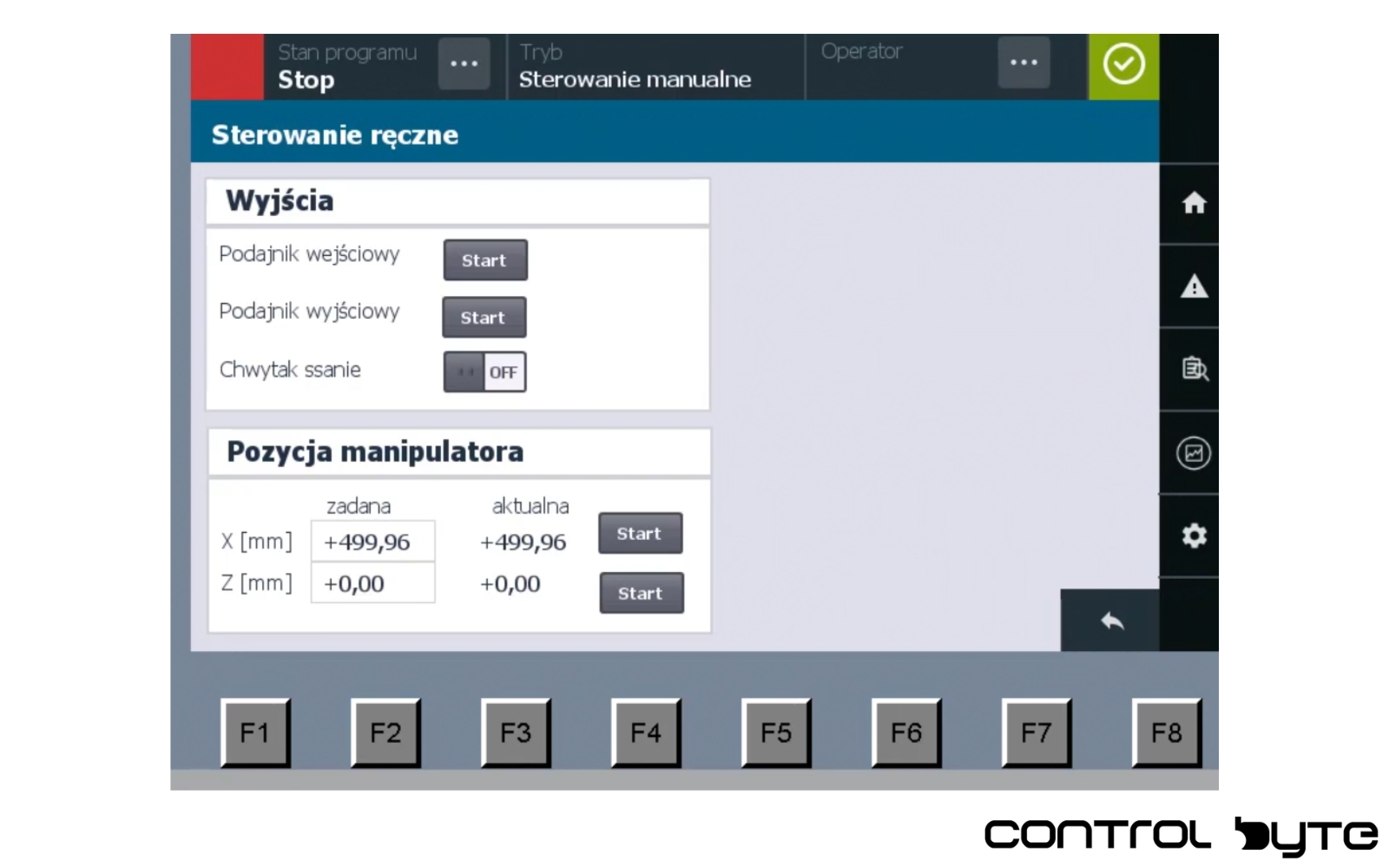

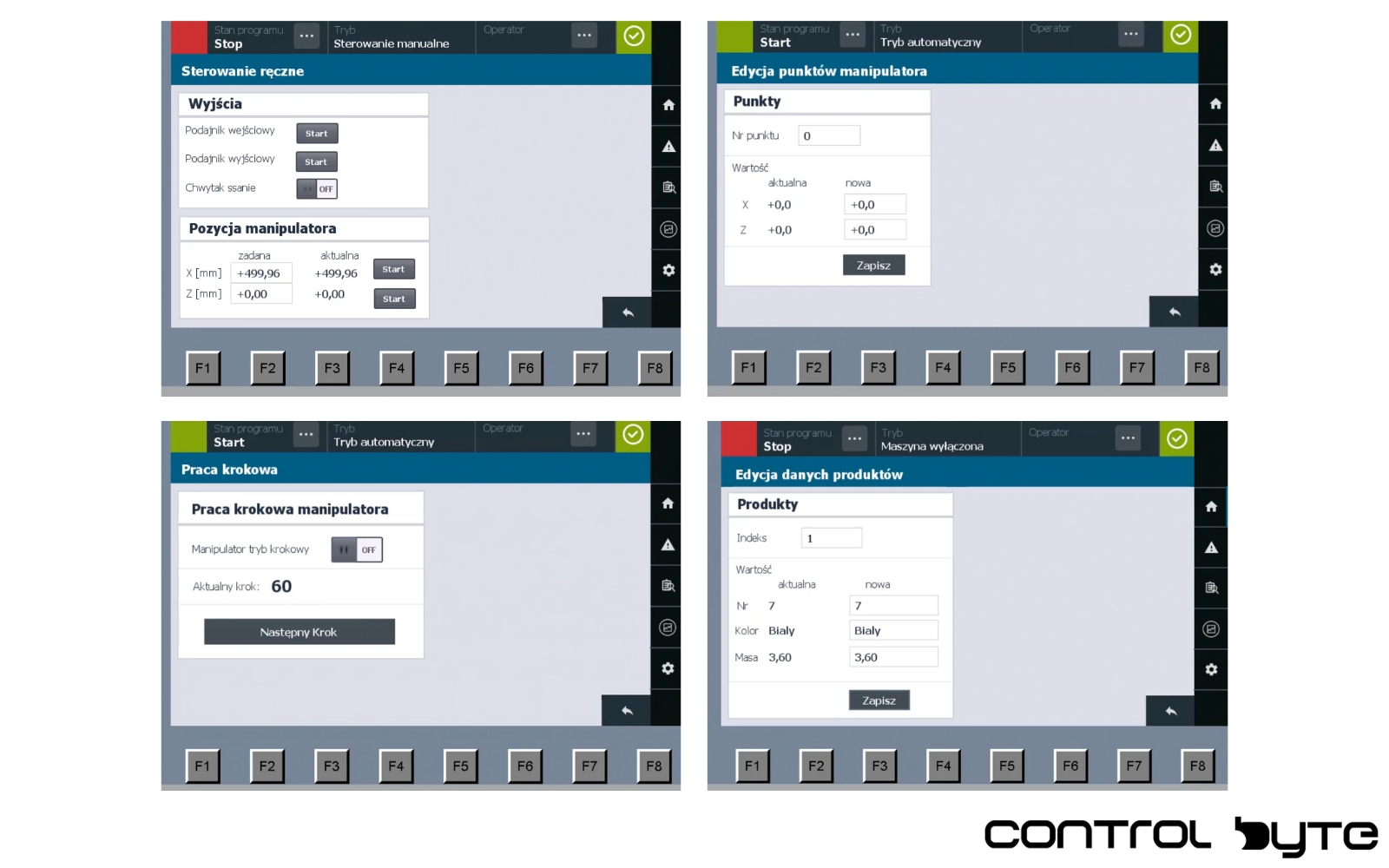

2. User Interface Design

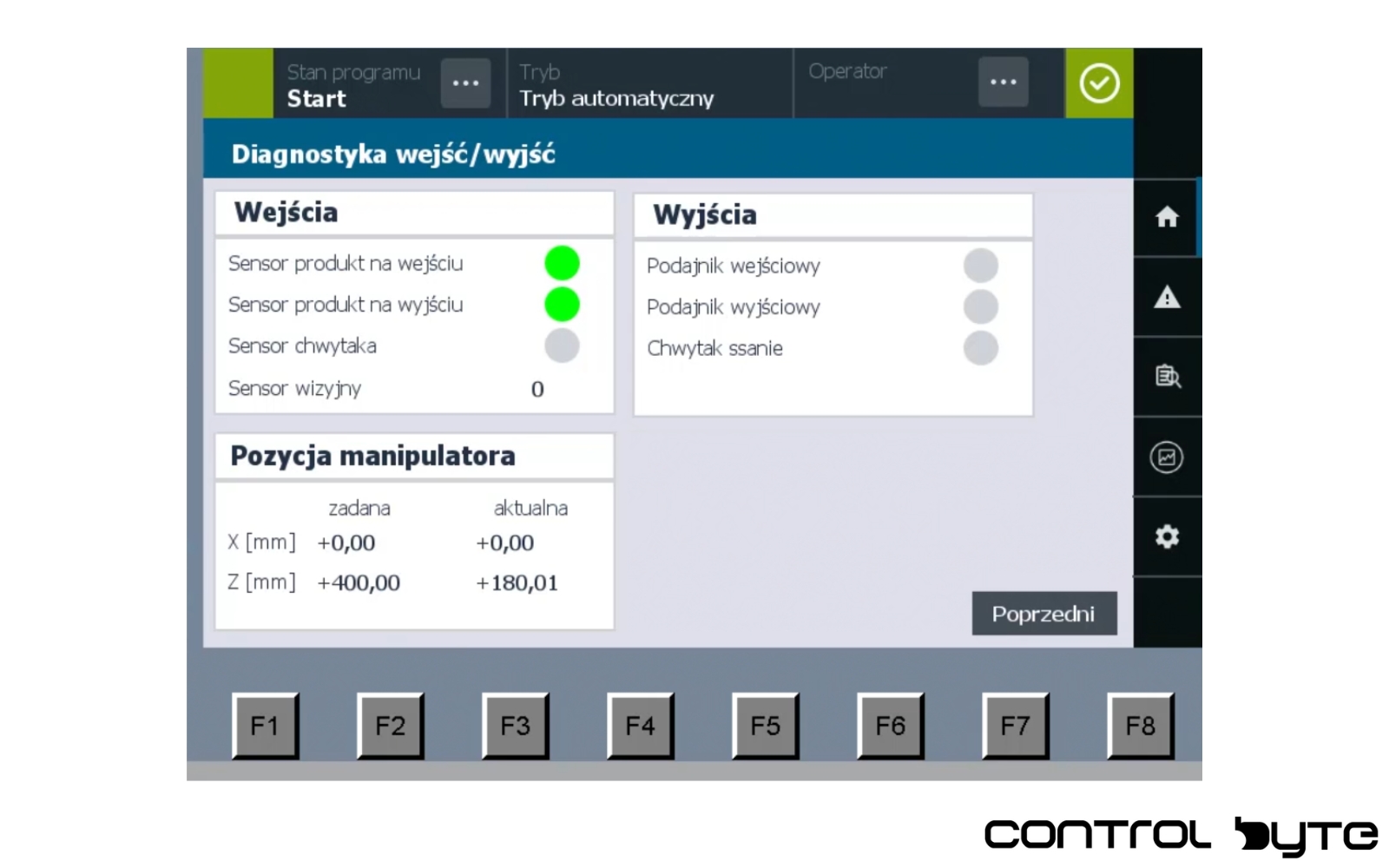

This stage focuses on designing the individual screens the operator will use. The interface must be clear, intuitive, and tailored to the specific application. Key information should be easily accessible, and alarm messages must be clear and understandable.

3. Implementation of Control Logic

Programming the HMI involves defining button actions, displaying process data, managing alarms, and ensuring communication with other devices. At this stage, designers outline the actions operators can take and the information they will have access to.

4. Testing and Validation

Every HMI system must undergo thorough testing before deployment. Testing involves verifying the correctness of all functions, assessing the system’s response to errors, and simulating various scenarios that may arise in real-world conditions.

5. User Training

The final step is training the operators. Even the most well-designed system will be ineffective if users do not know how to operate it. Training should cover all aspects of system usage, including responding to alarms and troubleshooting potential issues.

Best Practices in HMI Design

To create an effective and secure HMI system, it is crucial to adhere to key design principles:

Simplicity and Clarity

One of the most important aspects of HMI design is simplicity. HMI screens should be clear, with information presented in an understandable manner. Avoid overcrowding a single screen with too much information, as this can confuse the operator and hinder decision-making.

Consistency

All screens should maintain consistency in terms of color scheme, layout, and the method of presenting information. Operators should be able to navigate seamlessly between different screens without encountering unexpected changes in operation or design. Consistency enhances usability and reduces the learning curve.

Responsiveness and Speed

The HMI system should respond instantly to operator actions. Any delay can lead to frustration and increase the risk of operational errors. Ensuring that all functions are quick and responsive is crucial for maintaining efficiency and usability.

Safety

Safety is a critical aspect of HMI design. The system should include robust access authorization mechanisms to ensure that only authorized personnel can modify critical process parameters. Additionally, alarm messages must be clear and easily understood, allowing operators to respond promptly and effectively to emergency situations.

Challenges in HMI Programming

Programming HMI systems can be challenging due to the complexity of the process and the diversity of environments in which they operate. Some of the key challenges include:

Integration with Diverse Systems

HMI systems must work seamlessly with a wide range of devices and control systems. Ensuring full compatibility with various communication protocols and enabling smooth integration with existing infrastructure is critical. This requires a deep understanding of both the hardware and software components involved.

Managing Large Amounts of Data

Industrial processes generate an enormous volume of data that must be efficiently processed and presented to operators. It is important to ensure the data is displayed in a clear and comprehensible manner, enabling operators to easily interpret the information and make informed decisions.

Adapting to User Needs

Operators have varying levels of experience and skill. It is crucial to design an interface that is intuitive and tailored to the needs of different user groups. Advanced features should be accessible for experienced operators, while the interface for beginners should remain simple and easy to navigate.

The Future of HMI Systems

The future of HMI systems is closely tied to the development of technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), and Augmented Reality (AR). As these technologies become more widespread, HMI interfaces will be able to offer increasingly advanced features, including predictive analytics, intelligent recommendations, and interactive visualizations.

Integration with IoT will enable the collection of data from numerous sources and its centralized processing, facilitating even better process management. AI can assist in data analysis and decision-making, reducing operator workload and minimizing the risk of errors. Meanwhile, AR can provide more intuitive interactions with HMI systems, such as displaying critical information directly on an operator’s visor for enhanced situational awareness.

The Impact of Artificial Intelligence on HMI

Artificial Intelligence (AI) brings a new level of capability to HMI systems, automating many tasks that previously required manual operator intervention. With AI, it is possible to predict machine failures, analyze usage patterns, and automatically fine-tune process parameters. For example, machine learning algorithms can analyze historical data to identify trends, enabling proactive maintenance and preventing potential breakdowns.

AI enhances the efficiency and reliability of industrial systems, making HMI a smarter and more adaptive tool in complex environments. By reducing operator workload and improving predictive capabilities, AI-driven HMI systems contribute to increased productivity and minimized downtime.

The Use of Augmented Reality in HMI

Augmented Reality (AR) opens up entirely new possibilities for HMI systems. Operators can use devices like AR glasses to receive real-time information about machine status without needing to look at traditional screens. This enhances mobility and enables better process monitoring in the field. For example, operators can view step-by-step repair instructions in real time, significantly reducing response times during equipment failures.

Cloud Integration with HMI

The integration of HMI systems with cloud computing is becoming increasingly important. Process data can be stored in the cloud, allowing for analysis from anywhere in the world. This provides operators and managers with real-time access to data, enabling better planning and quicker responses to changes. Additionally, the cloud simplifies the creation of backups, minimizing the risk of data loss due to local hardware failures.

Personalization of HMI Interfaces

Personalizing HMI interfaces is essential for improving operator efficiency. Each user has unique preferences and working styles, making the ability to customize screens to individual needs a growing standard. For example, operators can select which information is most critical to them and place it on the main screen. This approach enhances work comfort, reduces response times to events, and minimizes the likelihood of errors.

Application of Predictive Analytics

Predictive analytics is becoming increasingly common in HMI systems. Leveraging data collected from machines and AI algorithms, HMI systems can forecast when failures might occur or when maintenance is required. Operators are notified in advance about potential issues, allowing them to prevent downtime and reduce maintenance costs. These capabilities are especially critical in large production facilities, where every minute of downtime can result in significant losses.

TP1500 COMFORT

MPN: 6AV2124-0QC02-0AX0

Brand: Siemens

Price: €4 784,00

TP700 Comfort Panel

MPN: 6AV2124-0GC01-0AX0

Brand: Siemens

Price: €579,00

TP900 WIN/CE OPERATOR PANEL

MPN: 6AV2124-0JC01-0AX0

Brand: Siemens

Price: €1 529,10

TP1200 COMFORT PANEL

MPN: 6AV2124-0MC01-0AX0

Brand: Siemens

Price: €1 593,75

SIMATIC HMI TP2200 COMFORT

MPN: 6AV2124-0XC02-0AX1

Brand: Siemens

Price: €2 750,00

KTP400 Comfort

MPN: 6AV2124-2DC01-0AX0

Brand: Siemens

Price: €415,00

SIMATIC HMI TP1900 COMFORT

MPN: 6AV2124-0UC02-0AX1

Brand: Siemens

Price: €2 499,00

SIMATIC KTP600 Basic Color

MPN: 6AV6647-0AC11-3AX0

Brand: Siemens

Price: €930,00

SIMATIC BASIC COLOR PANEL KT 10 TFT

MPN: 6AV6647-0AF11-3AX0

Brand: Siemens

Price: €2 576,00

Examples of HMI Applications in Industry

HMI systems are used across various industrial sectors. HMI systems play a crucial role in the food industry by enabling control over production processes, monitoring temperature and humidity, and managing packaging lines. Operators in the automotive industry use HMI to monitor robots, control assembly lines, and oversee quality assurance processes. In the energy sector, these systems help manage power grids, monitor turbine conditions, and control energy flows.

Ergonomics and HMI Interface Design

Ergonomics in HMI design is a critical factor influencing the efficiency and safety of operators. Designers must carefully arrange interface elements to ensure they are easily accessible and do not cause fatigue during extended use. Colors and fonts should be selected to minimize eye strain, and alarm messages must be distinctly differentiated from other information to ensure quick and accurate responses.

Application of Advanced Functions in HMI

Integration with SCADA and ERP

Modern HMI systems are increasingly integrated with SCADA (Supervisory Control and Data Acquisition) and ERP (Enterprise Resource Planning) systems. SCADA enables the collection, monitoring, and real-time analysis of process data, simplifying the management of multiple devices across various locations. Integration with ERP systems allows for synchronization of production data with managerial information, leading to efficient resource management and production optimization within the enterprise.

Monitoring the Technical Condition of Machines

HMI systems are also used for monitoring the technical condition of machines, which is essential for maintenance and preventing breakdowns. Through appropriate sensors, HMI can provide operators with data on component wear, oil levels, temperature, and other parameters that may impact the machine’s condition. This enables operators to take timely maintenance actions, reducing the risk of costly downtime.

Summary

HMI systems form the foundation of modern industrial automation, enabling operators to efficiently manage machines and processes. From simple button panels to advanced touch interfaces integrated with AI and IoT, HMI has evolved into an indispensable tool in every modern factory. The key aspects of effective HMI design include ergonomics, simplicity, safety, and personalization.

Today’s HMI systems, enhanced by technologies like predictive analytics, cloud computing, and augmented reality, are becoming even more efficient and user-friendly. Looking ahead, we can expect further integration of HMI with advanced technologies, driving better automation and optimization of industrial processes. This evolution will allow HMI interfaces to meet the growing demands of rapidly developing industries, offering operators an even more intuitive and secure way to control complex industrial systems

Discover more of our posts on our website: controlbyte.tech – happy reading!