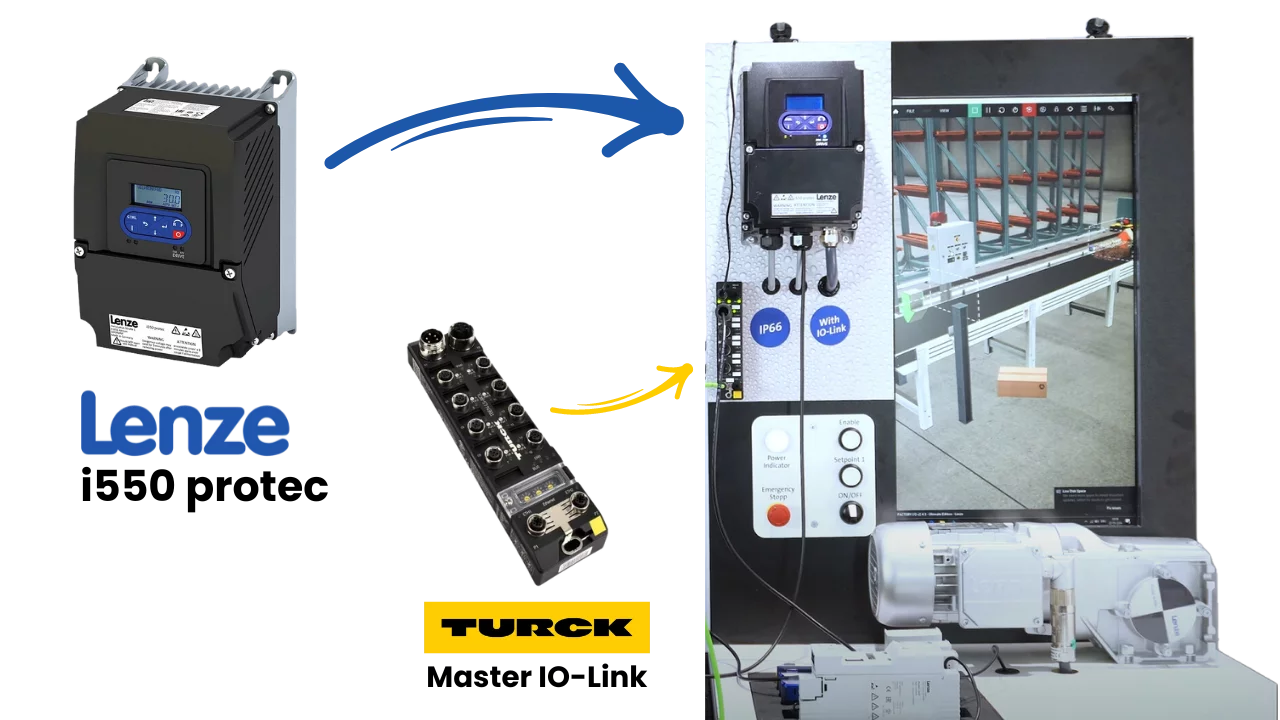

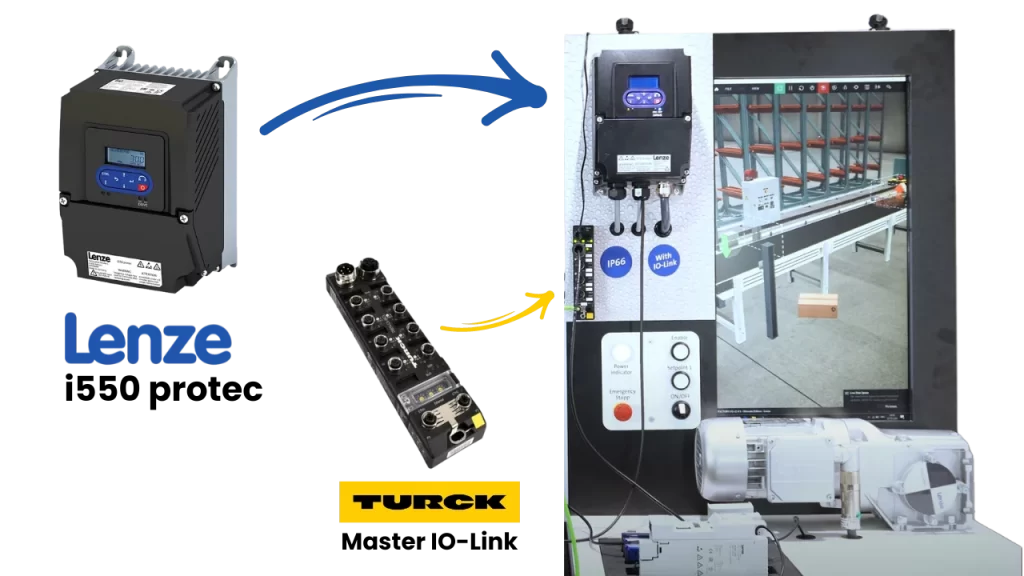

Lenze i550 protec Inverter

The award-winning i550 protec frequency inverter is based on proven technology used in control cabinet inverters and differs only in its tailored design and higher degree of protection. If there is insufficient space in the control cabinet or if it is necessary to mount the frequency inverter close to the motor in various machine modules, then this versatile and reliable device is the right solution. With the extension module, it is possible to use a service switch and control elements.

Key Features

- Decentralized drive with IO-Link V1.1 interface

- IP66 protection rating (dust and water resistant)

- Integrated diagnostic interface (micro USB) for maintenance activities

- Available in versions with or without a repair switch, with a keypad or Wi-Fi module for easy commissioning

- Optional “Safe Torque Off (STO)” function with SIL 3 (EN IEC 62061/EN IEC 61508) and Performance Level e (EN ISO 13849-1)

Applications of i550 protec

- Conveyor drives

- Travel drives

- Winding drives

- Hoisting drives

- Extruders

- Packaging machines

- Pumps

- Fans

Technical Data and Communication Options

| Technical Data | 0.37 … 75 kW |

| Connections | 1 AC 120 V |

| 1 AC 230 V | |

| 3 AC 230 V | |

| 3 AC 400 V | |

| 3 AC 480 V | |

| 3 AC 600 V | |

| 5 digital inputs | |

| 1 digital output | |

| 2 analog inputs | |

| 1 analog output | |

| 1 relay NO/NC | |

| DC Circuit | |

| Motor temperature monitoring | |

| Micro USB | |

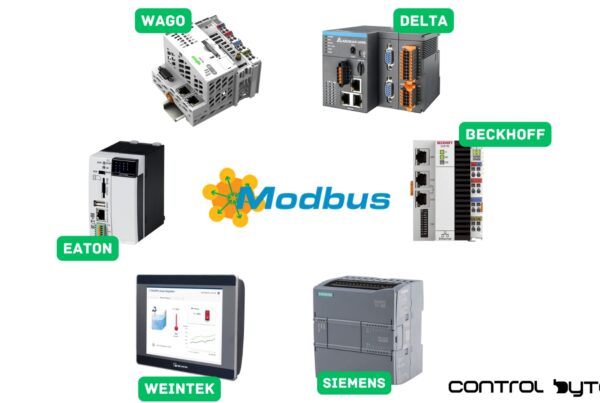

| Communication | CANopen |

| EtherCAT | |

| EtherNet/IP | |

| IO-Link | |

| Modbus RTU | |

| Modbus TCP | |

| PROFINET |

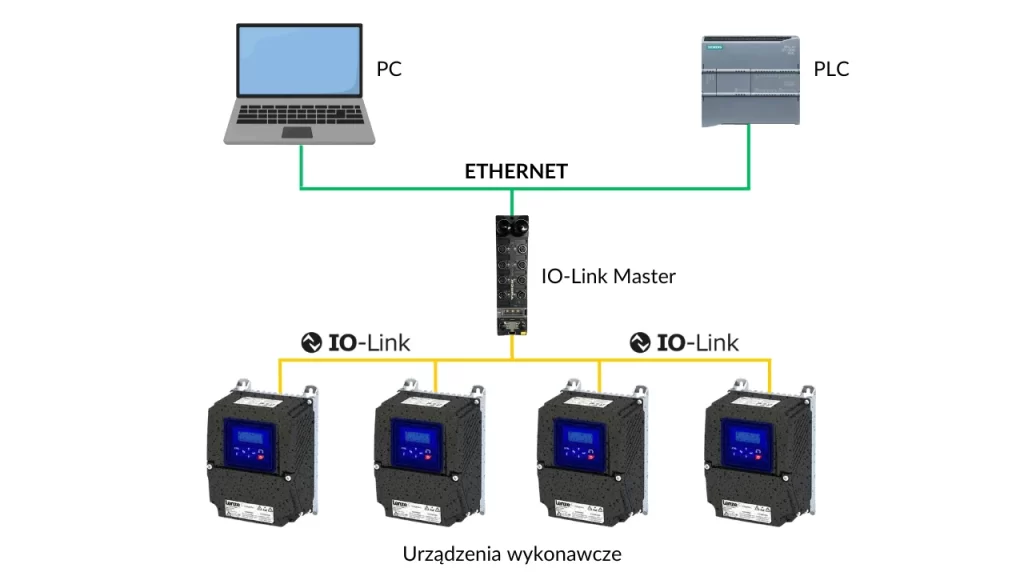

What is IO-Link?

IO-Link is a communication standard in automation that allows intelligent devices (sensors and actuators) to communicate with the control system.

IO-Link Applications

- Intelligent communication: IO-Link enables remote parameterization, diagnostics, and configuration of devices.

- Standardized installation: Regardless of device complexity, you can connect them using a standard three-wire cable.

- High signal quality: IO-Link provides excellent signal quality between devices and the control system.

- Cost reduction: IO-Link helps avoid unnecessary costs associated with various interfaces.

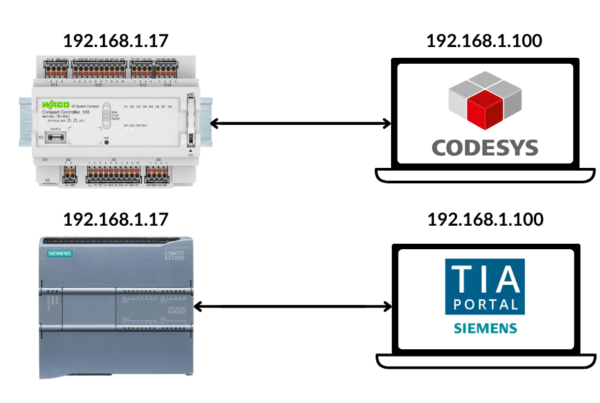

Connecting i550 protec Inverter to Siemens S7-1200 PLC

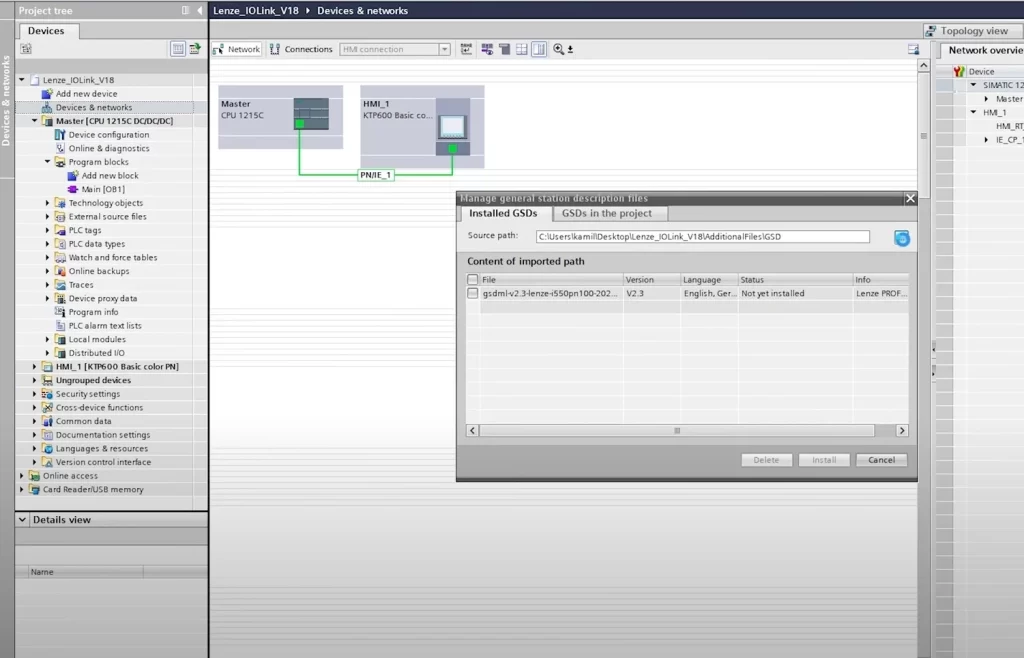

Configuring the S7-1200 Connection with an IO-Link Master in TIA Portal

First, to enable communication with the IO-Link Master in TIA Portal, download the GSDML file from the manufacturer’s website and load it in the Options -> Manage general station description files tab.

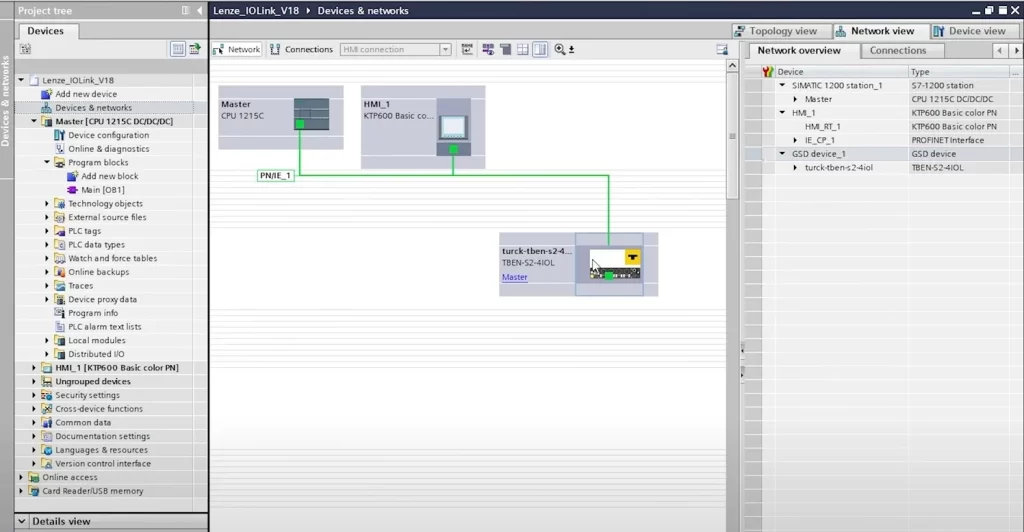

After loading the file, you can add the IO-Link Master to your project and connect it with other devices.

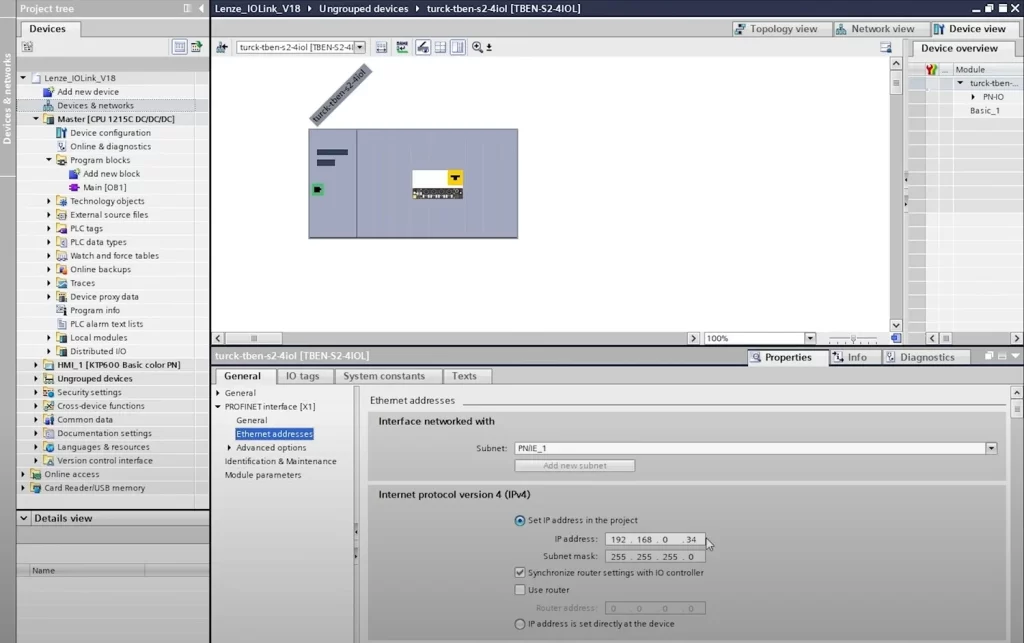

Double-clicking on the added device opens the configuration window. In the Ethernet addresses tab, assign an IP address to the IO-Link Master.

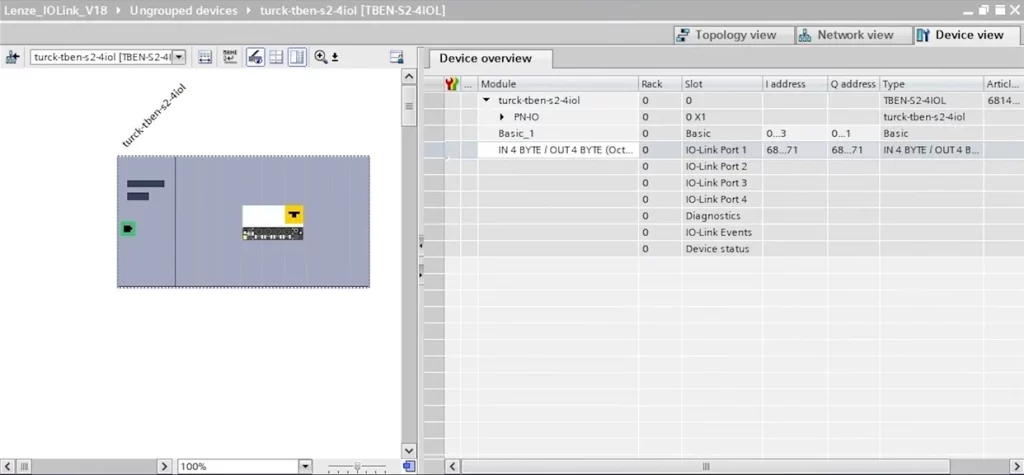

Now, configure the telegram exchange with the IO-Link Master. Since the inverter is connected to the Master’s first port, assign it 4 input bytes and 4 output bytes. By default, the IO-Link Master’s status is assigned to addresses I0-3 and Q0-1.

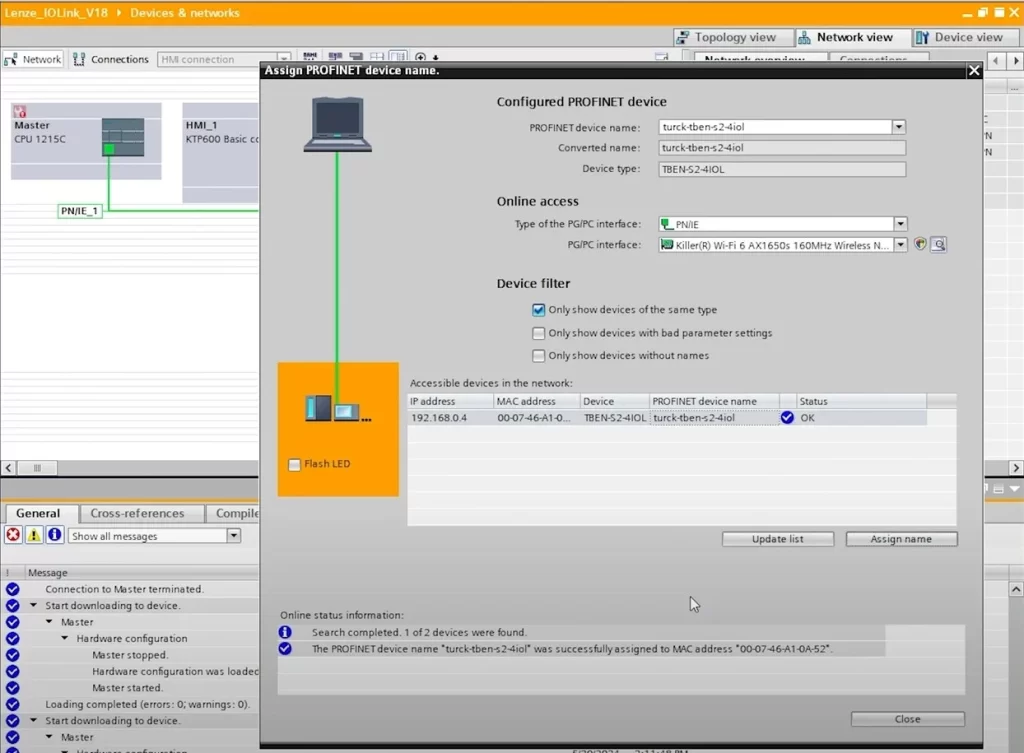

To save the changes, upload the program to the controller and assign a Profinet name to the IO-Link Master.

Accessing the IO-Link Master Web Panel

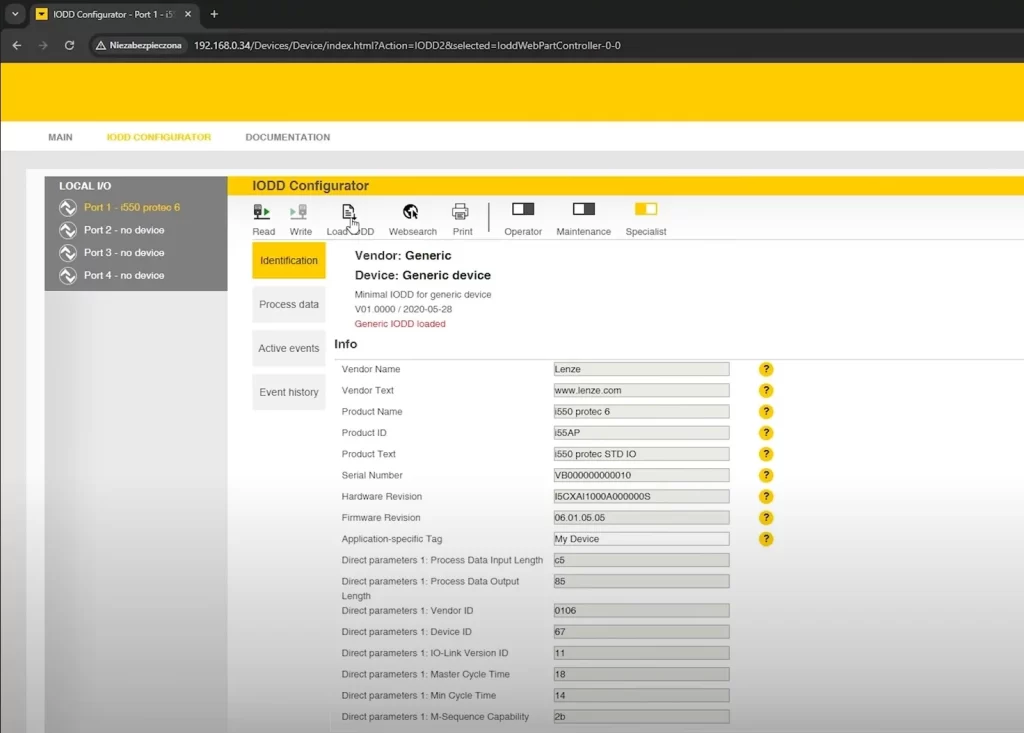

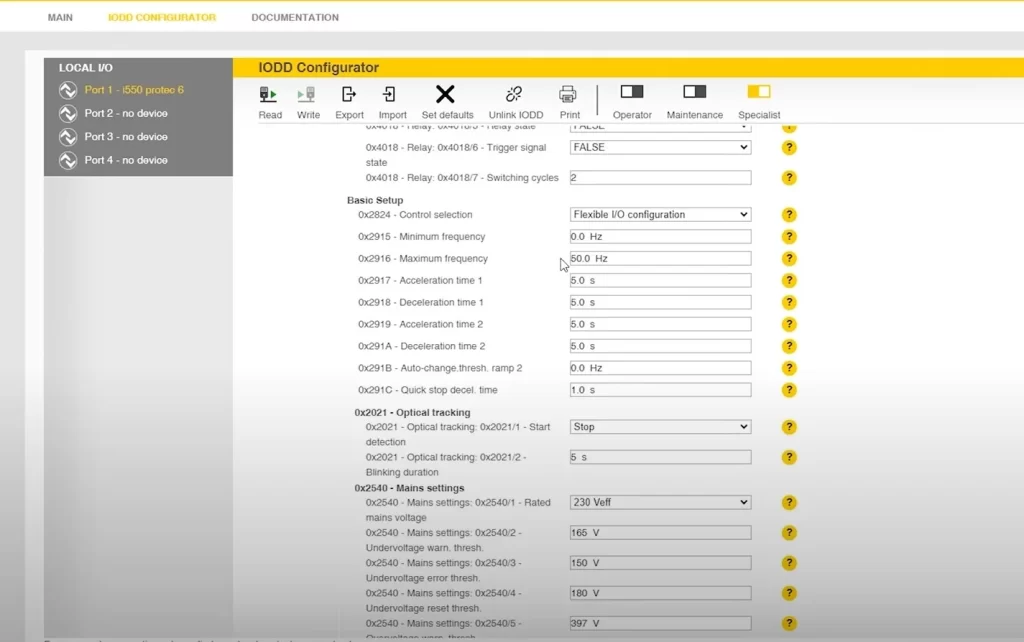

Using the IP address assigned earlier, you can log into the IO-Link Master’s management panel. REMEMBER! During the first login, you need to set a password. In the IODD tab, you’ll notice that the Lenze i550 protec inverter appears on the first port. To correctly read its parameters, load the IODD file, also downloadable from the manufacturer’s website.

After loading the IODD file, the full configuration of the Lenze i550 protec inverter becomes available.

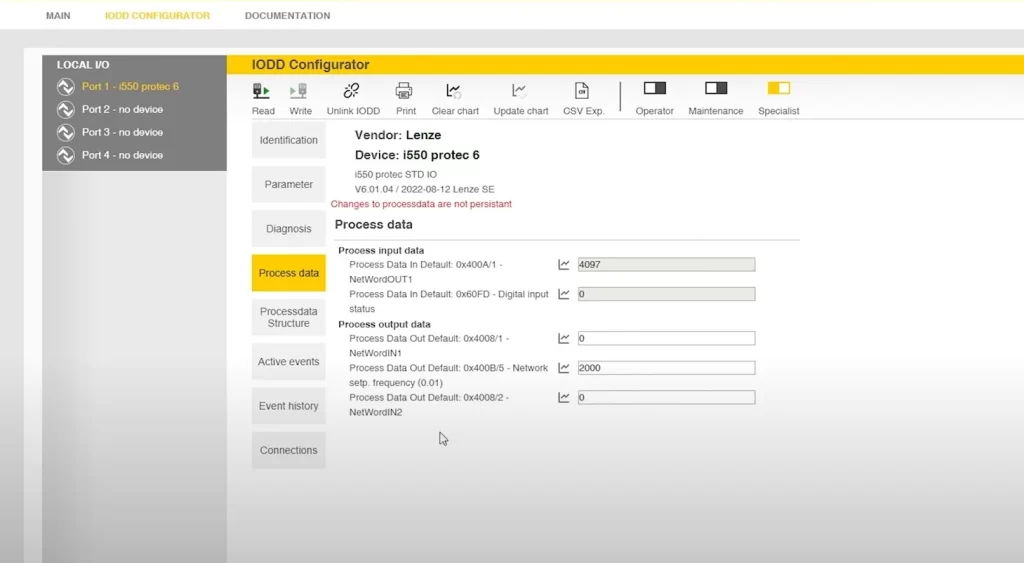

In the Process data tab, you can read status words and set individual values for control words.

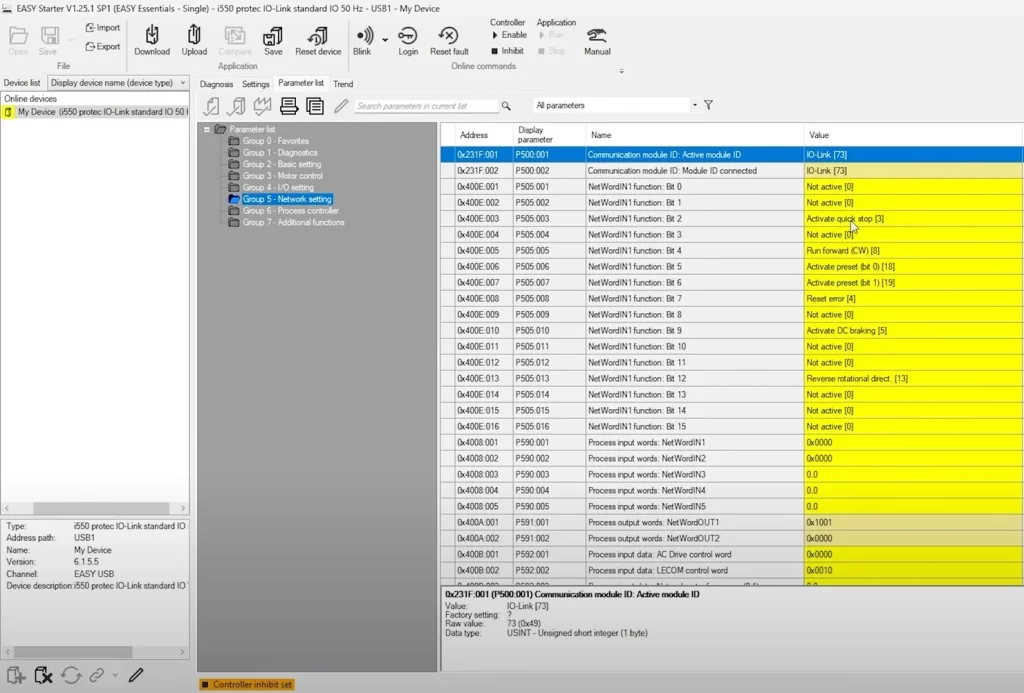

OPTIONAL You can also connect to the i550 protec inverter via a microUSB cable and configure the inverter using the EASY Starter software.

Controlling the i550 protec Inverter in TIA Portal

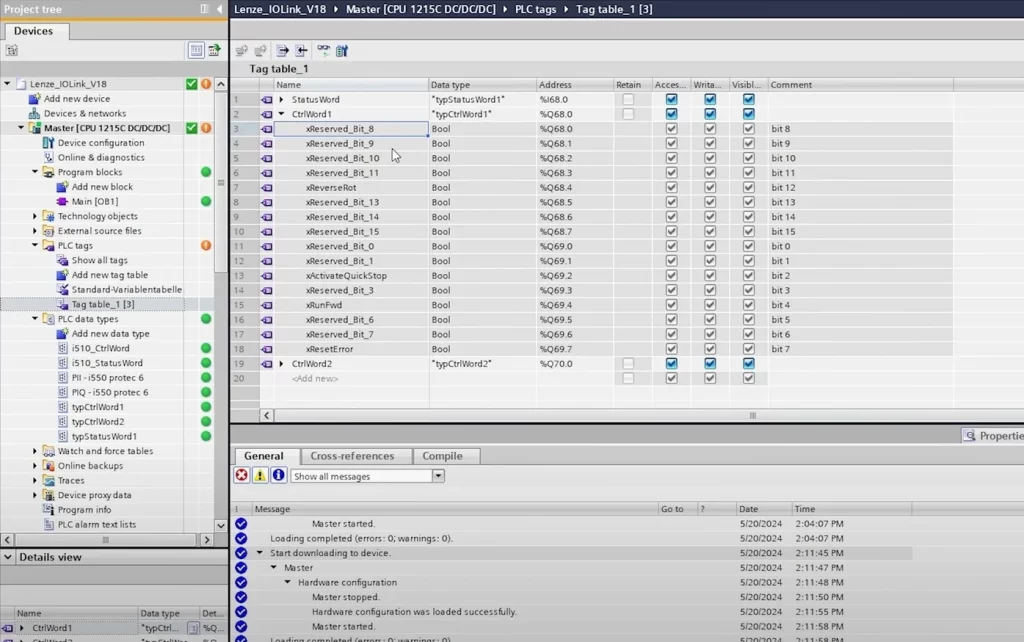

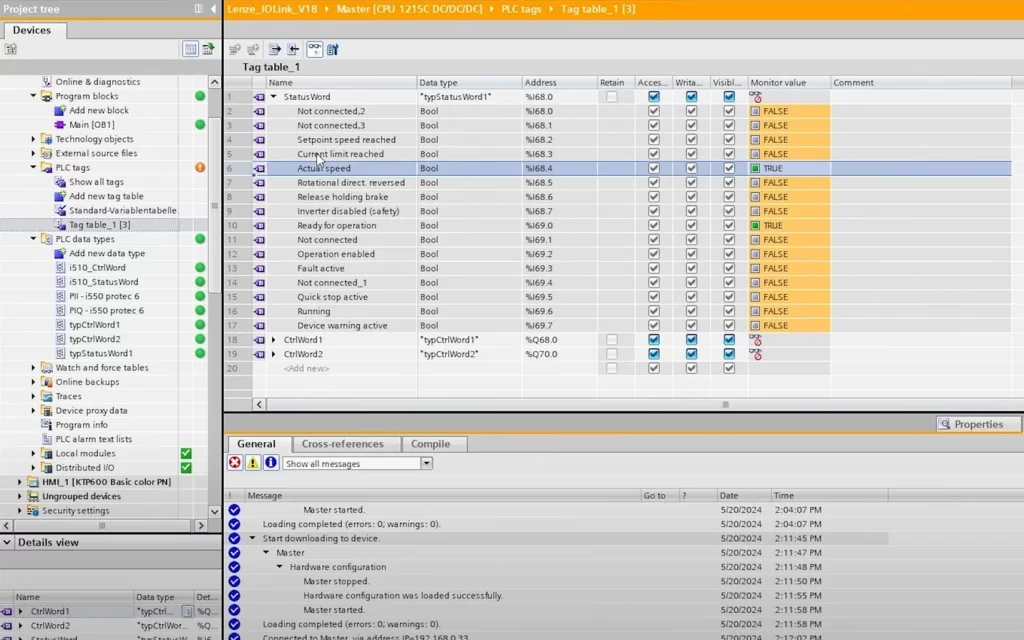

After completing the communication configuration, you can create data structures in TIA Portal (according to the device documentation) and assign them to the status and control words. Using a data structure significantly improves code readability and simplifies further programming.

In the status word, you can read parameters such as whether the inverter speed is synchronized with the set value or if the inverter is ready for operation.

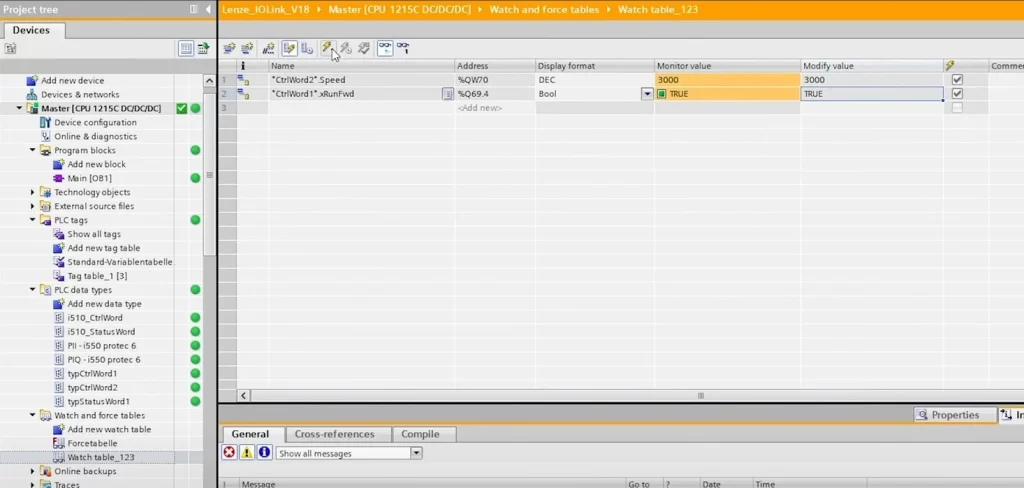

It’s time to set the inverter speed and test whether the communication works correctly. In the first control word, set the variable xRunFwd to TRUE, and in the second control word, set the variable Speed to 3000.

Learn More About Lenze i550 protec Communication via IO-Link

Summary The Lenze i550 protec inverter provides reliable and versatile drive solutions with easy configuration and diagnostics, making it a suitable choice for various industrial applications, especially when the inverter must be installed outside the control cabinet and exposed to adverse environmental conditions.

Thank you for reading! If you’re interested in learning more, explore our courses for in-depth training: Control Byte Courses.