Free PLC course outline

- Lesson #1: What Is It and Why Should Every PLC Programmer Know It? Part #1

- Lesson #2: How to install Codesys? Part #2

- Lesson #3: Write your first program in Codesys: Structured Text – Part #3

- Lesson #4: How to Create a Codesys Visualization in an Application? – Part #4

- Lesson #5: Introduction to Variables in CODESYS – Part #5

- Lesson #6: Data Structures in CODESYS: Practical Use of Arrays and Structures – Part #6

- Lesson #7: Advanced Data Types. Enumerations and Local vs. Global Variables – Part #7

- Lesson #8: Operators – Introduction and Practical Applications – Part #8

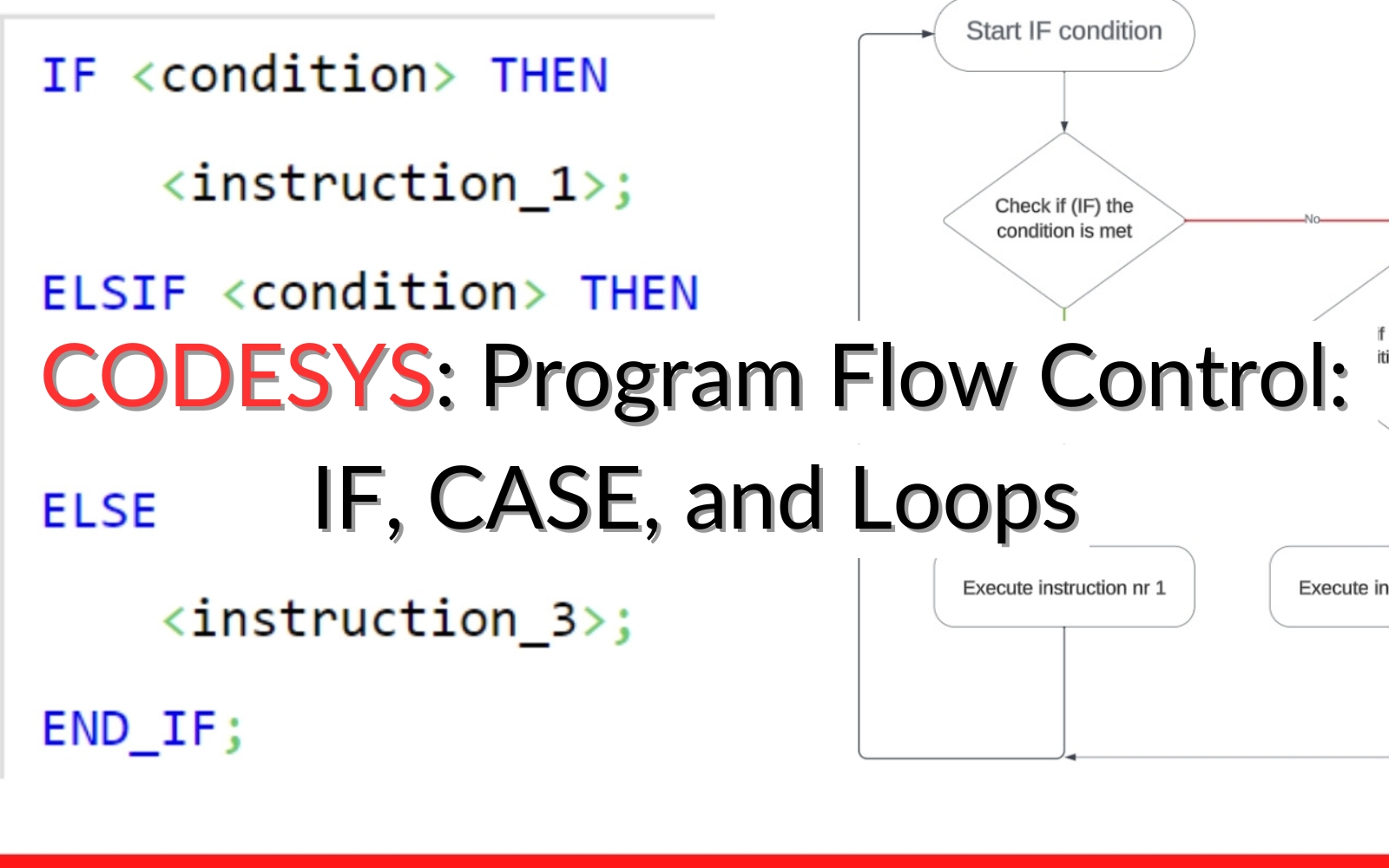

- Lesson #9: Program Flow Control: IF, CASE, and Loops – Part #9

Efficiently managing the flow of execution is crucial in PLC programming. In CODESYS, conditional statements and loops allow automation systems to make decisions and execute tasks dynamically. This section explores the IF, IF…ELSE, CASE…OF statements, and the FOR loop, providing examples of their usage.

Introduction to Program Flow Control

Control flow statements enable developers to execute specific parts of the program based on conditions. This is essential for handling decision-making processes and optimizing repetitive tasks in automation systems.

Why Use Flow Control?

- Make real-time decisions based on input conditions.

- Optimize system efficiency by executing only necessary logic.

- Reduce redundant code through loops and conditionals.

IF Statement in CODESYS

The IF statement is the most basic conditional statement. It executes a block of code only if a specified condition is TRUE.

Syntax:

IF condition THEN

// Code to execute if condition is met

END_IF;Example: Simple IF Statement

VAR

xButton1 : BOOL;

xSensor : BOOL;

iCounter : INT := 0;

END_VAR

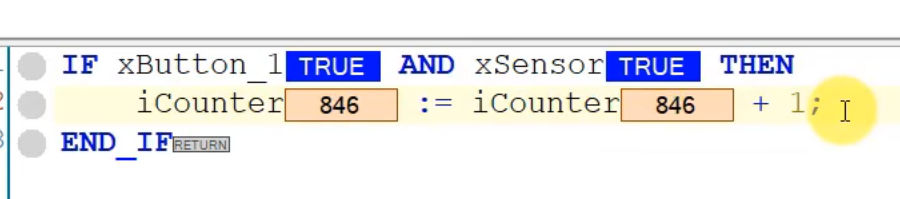

IF X_Button1 AND X_Sensor THEN

iCounter := iCounter + 1;

END_IF;Explanation: If both xButton1 and xSensor are TRUE, the counter increments.

Testing the IF Condition in a PLC Simulator

- Log in to the PLC simulator.

- Set xButton1 to TRUE.

- Set xSensor to TRUE.

- Observe iCounter incrementing.

Understanding the PLC Scan Cycle

The PLC cycle determines how often logic is executed in an automation system:

- Input Scan – Reads sensor and switch statuses.

- Program Execution – Executes logic based on inputs.

- Output Update – Sends signals to actuators.

- Housekeeping Tasks – Maintains communication and internal functions.

This cycle runs continuously, ensuring real-time automation control.

Understanding the PLC Execution Cycle

The PLC execution cycle determines how often logic is executed in an automation system. Each cycle consists of the following steps:

- Input Scan – Reads the status of sensors and switches.

- Program Execution – Executes logic based on input conditions.

- Output Update – Sends control signals to actuators.

- Housekeeping Tasks – Manages internal system functions and communication.

The PLC executes this cycle continuously at predefined intervals, ensuring real-time control over automation processes. In CODESYS, programs are executed cyclically, and the execution interval can be adjusted in milliseconds.

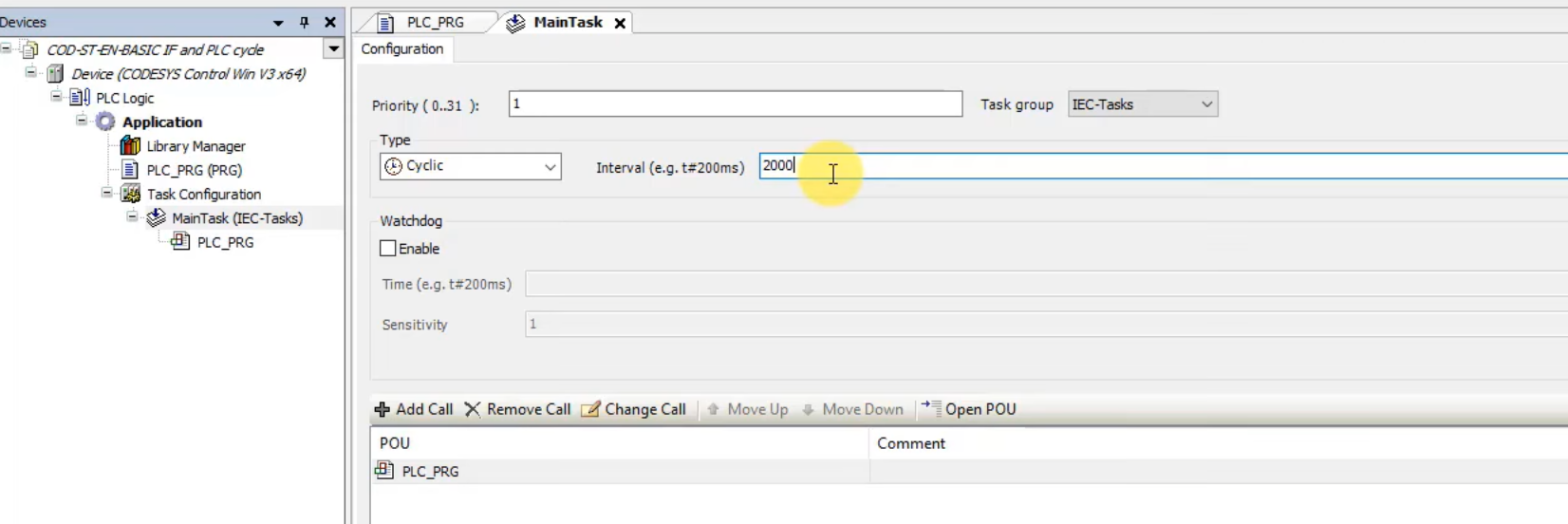

Configuring the Execution Cycle in CODESYS

To control execution speed:

- Open Task Configuration.

- Click on Main Task.

- Modify the execution interval (default: 20ms).

- Adjust it to 2000ms (2 seconds) to slow execution.

- Observe the effect on program execution speed.

With an interval of 2000ms, logic updates every 2 seconds, causing slower incrementation in counters.

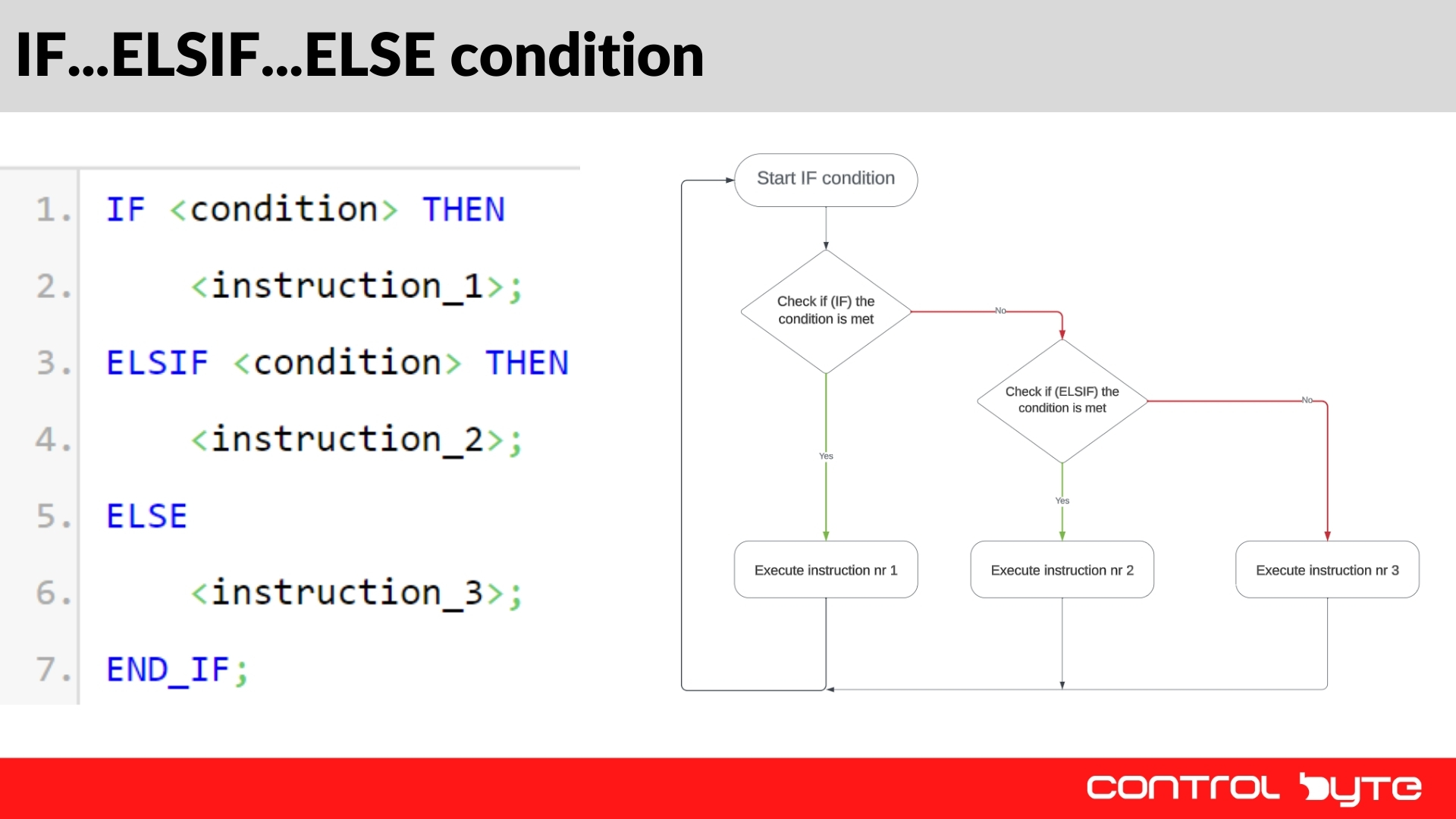

Implementing IF…ELSE in CODESYS

The IF…ELSE statement allows structured decision-making by executing different blocks of code depending on conditions.

Syntax of IF…ELSE Statement

IF condition THEN

// Code executed if condition is met

ELSIF another_condition THEN

// Code executed if first condition is FALSE, but this condition is met

ELSE

// Code executed if no conditions are met

END_IF;Example: Using IF…ELSE with Counters

VAR

xButton1 : BOOL;

xButton2 : BOOL;

iCounter : INT := 0;

END_VAR

IF xButton1 THEN

iCounter := iCounter + 1;

ELSIF xButton2 THEN

iCounter := iCounter - 1;

ELSE

iCounter := 0;

END_IF;Explanation:

- If xButton1 is pressed, the counter increments.

- If xButton2 is pressed, the counter decrements.

- If neither button is pressed, the counter resets to 0.

Testing IF…ELSE in a PLC Simulator

- Log into CODESYS simulator.

- Press xButton1 → Observe iCounter incrementing.

- Press xButton2 → Observe iCounter decrementing.

- Release both buttons → Observe iCounter resetting.

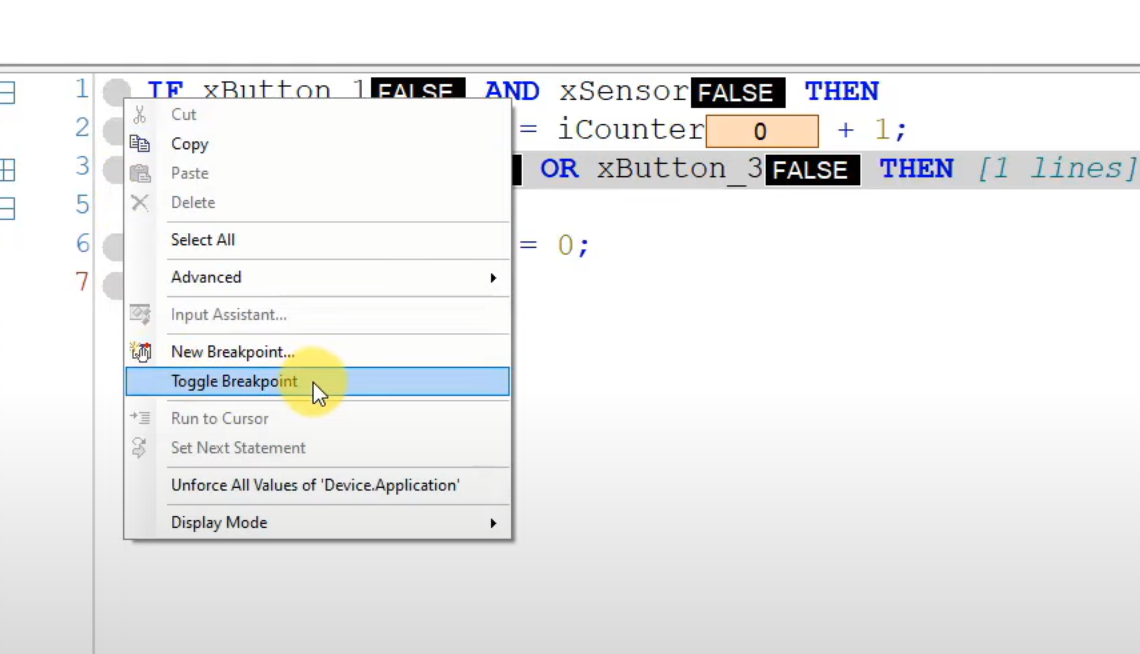

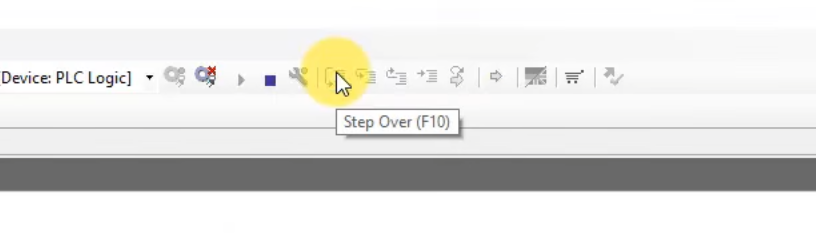

Debugging with Breakpoints

CODESYS provides a debugging tool that helps examine program execution by pausing at breakpoints.

Setting a Breakpoint in CODESYS

- Right-click on the desired line of code.

- Select Toggle Breakpoint.

- Run the program.

- The PLC pauses execution when it reaches the breakpoint.

At this stage, you can use Step Over to execute the next line and analyze logic execution step by step.

Analyzing Execution Flow

- If the first condition is met, the program executes its block and skips the ELSIF and ELSE parts.

- If the first condition is FALSE, it evaluates the ELSIF condition.

- If neither condition is met, it defaults to the ELSE block.

Using breakpoints and step-by-step debugging, developers can identify logic errors and optimize program execution.

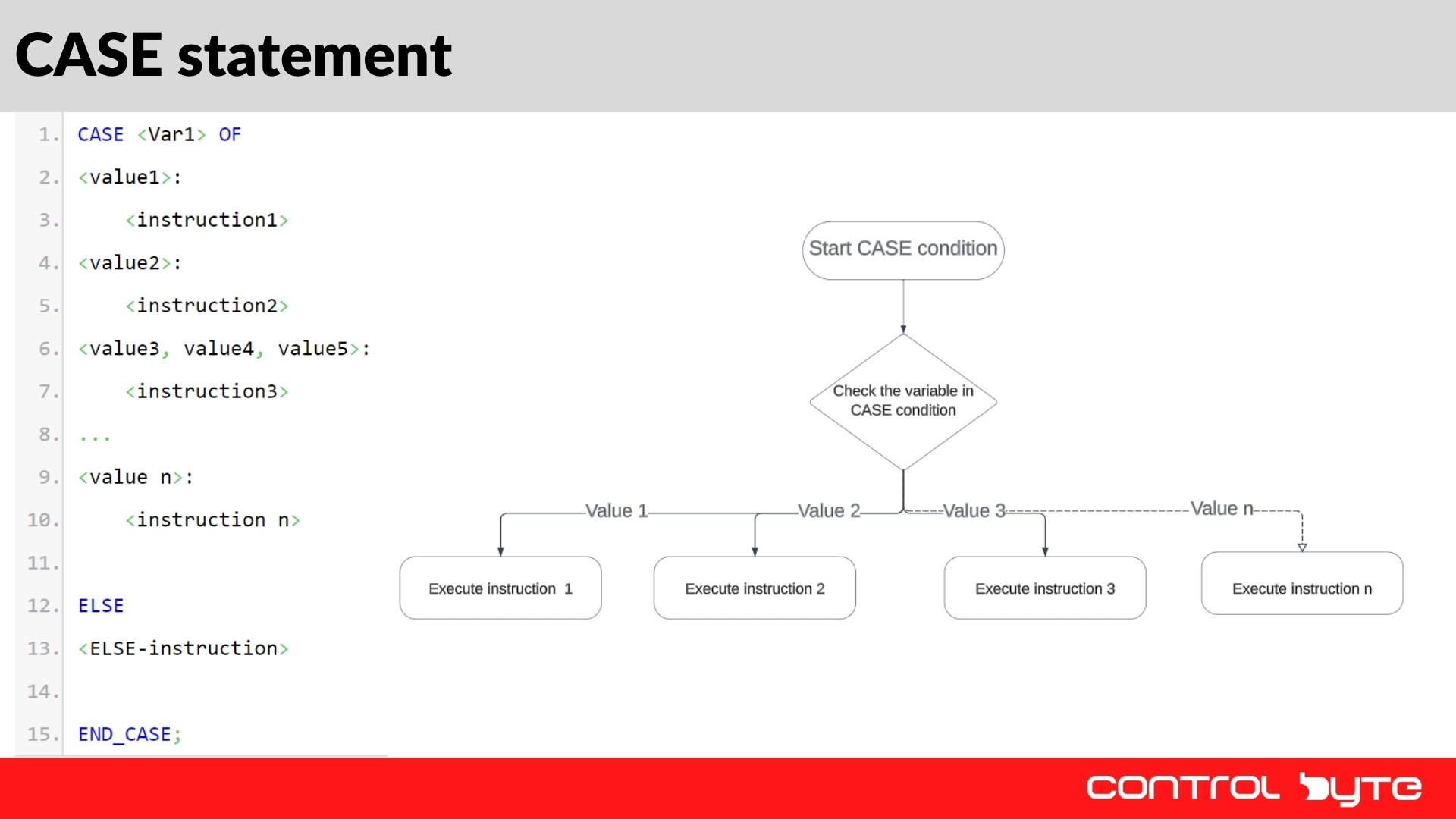

Using the CASE Statement for Flow Control

The CASE statement in CODESYS is a structured alternative to multiple IF…ELSE statements. It allows the program to execute different blocks of code based on the value of a single variable, making it particularly useful in automation applications where multiple conditions need to be evaluated.

Syntax of CASE Statement

CASE I_Var OF

0:

xLamp1 := TRUE;

xLamp2 := FALSE;

1:

xLamp2 := TRUE;

xLamp3 := FALSE;

10..20:

xLamp1 := TRUE;

xLamp2 := FALSE;

ELSE

xLamp1 := FALSE;

xLamp2 := FALSE;

xLamp3 := FALSE;

END_CASE;Explanation:

- If iVar is 0, Lamp 1 turns ON, Lamp 2 turns OFF.

- If iVar is 1, Lamp 2 turns ON, Lamp 3 turns OFF.

- If iVar is in the range 10 to 20, Lamp 1 turns ON, and Lamp 2 turns OFF.

- If iVar doesn’t match any case, the ELSE condition executes, turning off all lamps.

Testing the CASE Statement in CODESYS

- Log into the PLC simulator.

- Set iVar := 0 → Lamp 1 should turn ON.

- Set iVar := 1 → Lamp 2 should turn ON.

- Set iVar := 15 → Lamp 1 should turn ON.

- Set iVar := 25 → All lamps should turn OFF (ELSE case triggered).

Advantages of Using CASE Statement

- Cleaner and more readable code than multiple IF conditions.

- Improved execution efficiency since only one condition is evaluated.

- Easier debugging due to structured branching.

Implementing the FOR Loop in CODESYS

The FOR loop in CODESYS is used to repeat a block of code for a defined number of iterations. This is useful for handling arrays, repetitive calculations, and automation sequences.

Syntax of a FOR Loop

FOR iCounter := 0 TO 9 BY 1 DO

aArray[iCounter] := iVar + 10;

END_FOR;Explanation:

- The loop starts at 0 and ends at 9.

- BY 1 increments the loop counter by 1 in each iteration.

- Each array element aArray[iCounter] is assigned the value iVar + 10.

Declaring the Array

To use arrays in a FOR loop, declare them as follows:

VAR

aArray : ARRAY[0..9] OF INT;

iVar : INT;

iCounter : INT;

END_VARTesting the FOR Loop in CODESYS

- Log into CODESYS simulator.

- Initialize iVar with 5.

- Run the loop → Each array element should store iVar + 10 = 15.

- Modify iVar and rerun the loop → Observe changes.

Advantages of Using FOR Loops

- Automates repetitive tasks, reducing manual coding effort.

- Efficiently processes arrays without multiple assignments.

- Ensures structured and optimized execution.

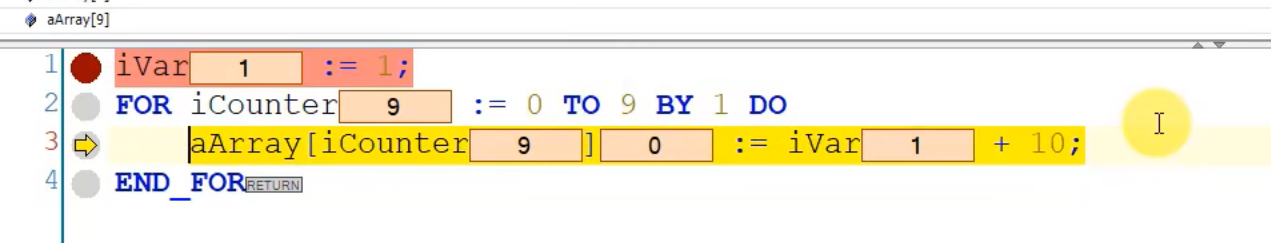

Debugging and Practical Use of FOR Loops in CODESYS

Understanding FOR Loops with Debugging

The FOR loop in CODESYS is used for iterating through a sequence and is commonly applied in automation programming for processing arrays, counters, and structured calculations. Using the debugger in CODESYS, we can analyze how the loop executes step by step.Observing the FOR Loop ExecutionTo analyze how the loop works in real-time, follow these steps:

- Set a Breakpoint: Right-click the first line of the loop and select Toggle Breakpoint.Start the PLC Simulation: Log in to the simulator and execute the program.Use Step Over (F10): This allows tracking how each iteration modifies variables.Tracking the Loop Counter in Debugger

- The loop counter I_Counter starts at 0 and increments with each iteration.The loop continues until iCounter reaches 9`.At each step, an operation is performed on an array element.Modifying the FOR Loop in CODESYS

Original Implementation

FOR iCounter := 0 TO 9 BY 1 DO

aArray[iCounter] := iVar + 10;

END_FOR;Each array element aArray[iCounter] stores the value iVar + 10. Modifying the Loop for Dynamic Computation. We can modify the loop to add the counter value:

FOR iCounter := 0 TO 9 BY 1 DO

aArray[iCounter] := iVar + iCounter;

END_FOR;Now, each row in the array is incremented by the loop index, producing a different result for each element. Testing the New Loop in Debugger

Execute the modified FOR loop. Observe array changes in real-time as values update dynamically. Reset all variables via Reset Warm to test from the beginning.

Practical Applications of FOR Loops in Automation

Processing sensor data stored in arrays. Iterating through multiple actuators for sequential control. Implementing structured control logic in industrial processes.

Summary

The article discusses key program flow control instructions in CODESYS, such as IF, IF…ELSE, CASE…OF, and the FOR loop. The IF statement allows executing a specific block of code when a given condition is met, which is useful for real-time decision-making. The IF…ELSE extension enables the execution of an alternative block of code when the initial condition is not met, allowing for more complex decision scenarios. The CASE…OF statement is used to select one of multiple code blocks based on a variable’s value, simplifying the management of multiple conditions. The FOR loop allows a block of code to be executed multiple times for a defined number of iterations, making it efficient for working with arrays or repetitive tasks. The article also highlights the importance of the PLC scan cycle, which includes reading inputs, executing the program, updating outputs, and performing system tasks to ensure continuous process control. Additionally, debugging techniques in CODESYS, such as setting breakpoints, are presented to help identify and resolve issues in the code.

Free PLC course outline

- Lesson #1: What Is It and Why Should Every PLC Programmer Know It? Part #1

- Lesson #2: How to install Codesys? Part #2

- Lesson #3: Write your first program in Codesys: Structured Text – Part #3

- Lesson #4: How to Create a Codesys Visualization in an Application? – Part #4

- Lesson #5: Introduction to Variables in CODESYS – Part #5

- Lesson #6: Data Structures in CODESYS: Practical Use of Arrays and Structures – Part #6

- Lesson #7: Advanced Data Types. Enumerations and Local vs. Global Variables – Part #7

- Lesson #8: Operators – Introduction and Practical Applications – Part #8

- Lesson #9: Program Flow Control: IF, CASE, and Loops – Part #9