In this article, you will learn about the resources and tools worth using if you are starting with automation or want to expand your knowledge. Here are the most frequently asked questions by our viewers and readers:

- Where to gain knowledge about automation system design and programming?

- Which design books do you recommend?

- Which standards and directives are useful in design?

- What are good tools for designing electrical diagrams for beginners?

- To what extent can online courses aid in my development?

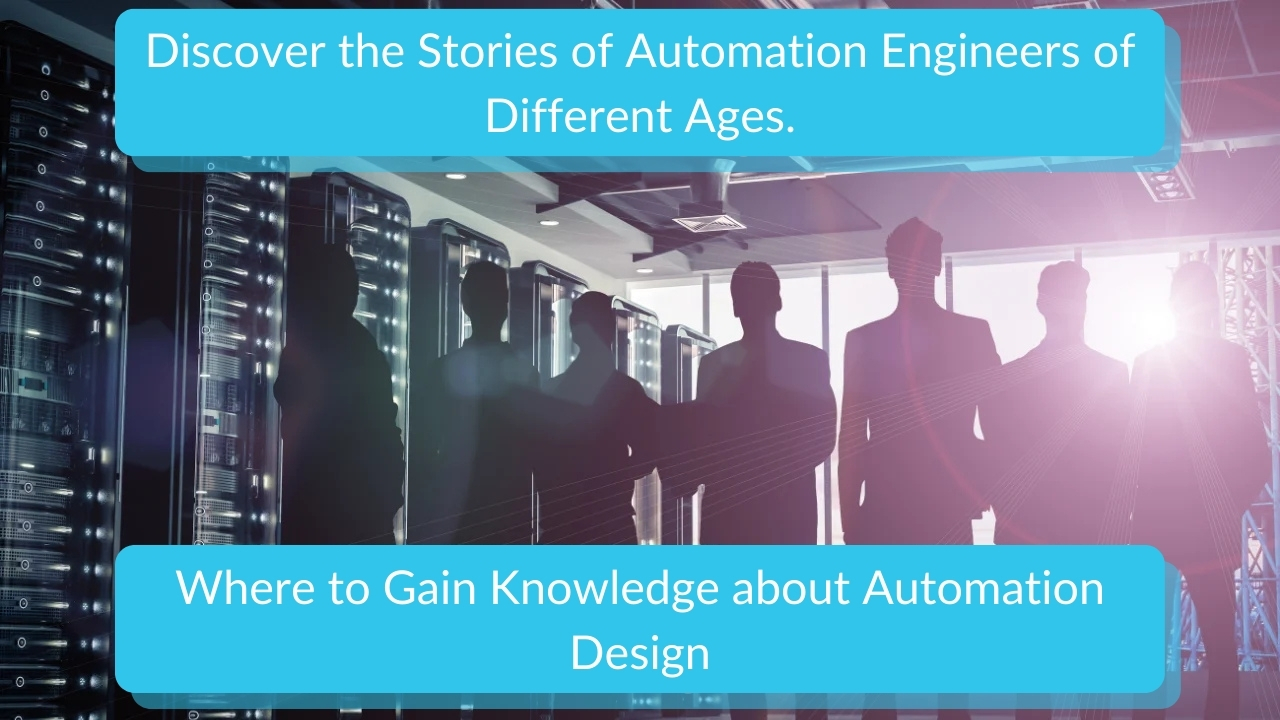

Learn About the Educational Paths of Automation Engineers from Various Age Groups

Maciej Kurantowicz (32 years old)

My interest in automation started thanks to articles in the popular magazine “Elektronika Praktyczna” (“Practical Electronics”). At that time, I was attending a technical high school with an electronics focus. We mainly got our current knowledge from magazines and books. I remember that at the end of my favorite monthly issue, there was a section dedicated to industrial automation, describing a line for cutting plastic tubes. That was the first time I learned what a PLC controller was! I thought that automation was a much more interesting field than electronics.

For me, all the foundational knowledge in programming and basic electrical engineering came from the long hours spent in classes and practical exercises in technical school. University turned out to be a huge disappointment in terms of practical topics.

Where did I gain my knowledge of automation design and programming? I got an internship at a car parts factory near Wrocław, working in the maintenance department. The hall was equipped with dozens of CNC machines and a few automated production lines. In such an environment, I quickly learned the essential aspects needed by every automation engineer at work:

- Analyzing technical documentation and electrical diagrams

- Familiarity with key automation devices and components

- Modifying existing electrical diagrams

- Troubleshooting failures and preventing future ones

- Pricing automation projects

Where Did I Draw Knowledge From?

For me, the most important was contact with experienced colleagues who didn’t “sell” all their knowledge but could point to valuable materials. We used machine technical documentation, manufacturer documentation for automation devices, and certain machine standards. During internships, it’s important that you can count on the support of more experienced colleagues, and nothing can replace that!

I continued my career in automation but moved on to commercial companies. That was where I first encountered new ways of gaining knowledge, namely online courses and tutorials. It was a tremendous leap forward for me!

I could independently adjust my time for learning and work. This helped me quickly become a specialist and advance to higher positions. You already know the rest of my story, as for several years, you have been able to follow my challenges in the automation market as the owner of ControlByte 🙂

Kamil Biedulski (32 years old)

I graduated from a general high school with a language focus. I’ve always had a knack for industrial machines, which may be due to the fact that several people in my family work in mechanics and automation. As a result, I decided to study Automation and Robotics at the Faculty of Mechanical Engineering. The studies gave me a broader view of what I could do in the industry. My studies culminated in designing and programming a Delta robot from scratch.

During my studies, I had a year-long internship in the maintenance department, where I learned how to program PLCs and modernize machines. As a newly graduated engineer, I went to a design office where I designed mechanical systems using CATIA software. It is one of the most comprehensive and technologically advanced software tools supporting engineering work, designed for 3D design. It is used in many demanding industries, so it is chosen by major players in the automotive and aviation industries, as well as by engineers, constructors, architects, CNC machine programmers, and designers worldwide.

Working as a mechanical designer (6 months) gave me valuable experience, but my true calling was the position of automation programmer! Programmers in the industry earn much more than designers – that was my second motivator! I moved to an integration company, and that’s where the real challenges began. What did I need to learn?

- Drawing electrical diagrams

- Pricing automation projects

- Choosing components

- Quickly and efficiently starting up an industrial machine

- Programming PLC controllers

- Robot programming

- Much more

Where Did I Draw Knowledge From?

I’m an automation engineer who dives into the smallest detail. Apart from the theory I learned in college and from books, I focus on practice. I made it a priority to first understand the specifics of a machine or automation device. By reviewing technical documentation and testing sample applications in the workshop, I gained practical insights. To further enhance my knowledge, I supplemented these experiences with both in-person and online courses. In my view, only this kind of combination results in a fully functional machine as the final outcome!

Working in UR and the integration company allowed me to acquire the necessary skill set to independently carry out control system projects for machines. I currently run my own company. We design custom machines and provide control systems for machines and production lines. We collaborate with the largest manufacturing companies (automotive) in Lower Silesia.

Olaf (automation engineer at ControlByte – 24 years old)

I graduated from a technical high school in mechatronics. The natural choice was to continue my path by choosing Automation and Robotics at WAT University. I’m lucky to enter the workforce when remote work is common. Surprisingly, it is also common in automation. That’s why I decided to try my luck and look for work in a small company that allows remote work. It worked! For over a year, I’ve been working at ControlByte, gaining knowledge directly from my more experienced colleagues.

My first independent project was an application in the building automation sector. I was thrown in at the deep end. I had to handle everything myself: from contacting the client to preparing the electrical diagram to programming the PLC controller. After completing the project, I now know where to look for knowledge! I needed a few books, automation manufacturers’ publications, technical documentation from the manufacturer, but sometimes that’s not enough! Contact with the technical support of the PLC controller manufacturer I was working with was very helpful.

My subsequent projects went more smoothly, but online courses turned out to be an invaluable source of knowledge. This modern form of education allowed me to fill in gaps and take on more ambitious projects.

Szymon (junior automation engineer at ControlByte – 20 years old)

I have just graduated from a technical high school in mechatronics. For several years, I have been doing small projects on my own, such as building electrical installations or setting up control cabinets. I wouldn’t recommend general high school to anyone. Our school emphasizes technical subjects. We program simple LOGO controllers, and the practical exam involves analyzing and modifying pneumatic or electrical diagrams. This is the knowledge I rely on in my daily work at ControlByte. I am currently waiting for my first major project, but I know our company has the know-how. Experienced colleagues can quickly point to the right resources and tools worth using.

Machine Directives and Standards

The question about which standards to use comes up in every one of our LIVE broadcasts!

So, we have prepared a list that you can start using today. Here is your list:

General Safety Standards

- PN-EN ISO 12100 Safety of machinery – General principles for design – Risk assessment and risk reduction

- PN-EN ISO 13849-1:2016-02 “Safety of machinery – Safety-related parts of control systems – Part 1: General principles for design”

- PN-EN ISO 13849-2 Safety of machinery – Safety-related parts of control systems – Part 2: Validation

- PN-EN 60204-1 Safety of machinery – Electrical equipment of machines – Part 1: General requirements

- PN-EN 62061 Safety of machinery – Functional safety of electrical, electronic, and programmable electronic control systems

- PN-EN 1037 Safety of machinery – Prevention of unexpected start-up

- PN-EN ISO 4413 Hydraulic fluid power – General rules and safety requirements for systems and their components

- PN-EN ISO 4414 Pneumatic fluid power – General rules and safety requirements for systems and their components

Guards

- PN-EN ISO 14120 Safety of machinery – Guards – General requirements for the design and construction of fixed and movable guards

- PN-EN ISO 13857 Safety of machinery – Safety distances

- PN-EN 349 Safety of machinery – Minimum gaps to avoid crushing of body parts

- PN-EN 953 – Mechanical parameters of guards and guarding strategy

Movable Guards – Flaps, Hoods, Doors, Gates

- PN-EN ISO 14119, Safety of machinery – Interlocking devices associated with guards – Principles for design and selection

Protective Devices – Approaching Hazardous Areas

- PN-EN 61496-1 Safety of machinery – Electro-sensitive protective equipment

- PN-EN ISO 13856-1,-2,-3 Safety of machinery – Pressure-sensitive protective devices

Protective Devices – Approaching the Hazard Zone – Light Curtains, Laser Scanners, Safety Vision Systems, Safety Mats, Rails, Plates, Bars, Bumpers

- PN-EN 61496-1 Safety of machinery – Electro-sensitive protective equipment

- PN-EN ISO 13856-1, -2, -3 Safety of machinery – Pressure-sensitive protective devices

Remote Support – Two-Hand Control Devices (Presses)

- PN-EN 574 Safety of machinery – Two-hand control devices – Functional aspects – Principles for design

- PN-EN ISO 13855 Safety of machinery — Positioning of protective equipment concerning approach speeds of parts of the human body

Local Support – Mode Selection, Enabling Devices, Process Parameter Monitoring, Safe Drive Functions

- PN-EN 61800-5-2 Adjustable speed electrical power drive systems – Part 5-2: Safety requirements – Functional

Additional Protective Measures (Emergency Stop – E-stop)

- PN-EN ISO 13850 Safety of machinery – Emergency stop function – Principles for design

Type C Standards Contain Requirements for Specific Machine Categories

- PN-EN 415-6 Safety of packaging machines

- PN-EN ISO 10218-1:2011E Robots and robotic devices – Safety requirements for industrial robots – Part 1: Robots

- PN-EN ISO 10218-2 Robots and robotic devices – Safety requirements for industrial robots – Part 2: Robot systems and integration

- ISO 10218-1 and ISO 10218-2 – Safety requirements for collaborative robots

Standards for Integration of Production Lines

PN-EN ISO 11161 Industrial automation systems – Safety of integrated manufacturing systems – Basic requirements

Building Electrical Standards

- PN-HD 60364-5-51:2011 – Electrical installations in buildings — Part 5-51: Selection and erection of electrical equipment — General requirements

- PN-HD 60364-5-54:2011 – Low-voltage electrical installations — Part 5-54: Selection and erection of electrical equipment — Earthing arrangements and protective conductors

- PN-EN 60445:2018-01 Basic and safety principles for human interaction with machinery, marking, and identification — Identification of equipment terminals and conductor terminations as well as conductors

- PN-EN 60446:2010 – Basic and safety principles for human interaction with machinery, marking, and identification — Identification of conductors by colors or alphanumeric codes

- PN-HD 60364-1:2010 Low-voltage electrical installations – Part 1: Fundamental requirements, assessment of general characteristics, definitions

- PN-IEC 60364-3:2000 Electrical installations in buildings – Assessment of general characteristics

- PN-HD 60364-4-41:2009 Low-voltage electrical installations – Part 4-41: Protection for safety – Protection against electric shock

- PN-HD 60364-4-42:2011 Low-voltage electrical installations – Part 4-42: Protection for safety, protection against thermal effects

- PN-HD 60364-4-43:2010 Low-voltage electrical installations – Part 4-43: Protection for safety – Protection against overcurrent

- PN-HD 60364-4-442:2012 Low-voltage electrical installations – Protection for safety – Protection against transient overvoltages due to earth faults in high and low voltage systems

- PN-HD 60364-4-443:2006 Electrical installations in buildings – Part 4-443: Protection for safety – Protection against voltage disturbances and electromagnetic disturbances – Protection against atmospheric or switching surges

Building Electrical Standards (Continued)

- PN-HD 60364-4-444:2010 Low-voltage electrical installations – Protection for safety – Protection against voltage disturbances and electromagnetic disturbances

- PN-IEC 60364-4-45:1999 Electrical installations in buildings – Protection for safety – Protection against undervoltage

- PN-IEC 60364-4-473:1999 Electrical installations in buildings – Protection for safety – Implementation of measures ensuring safety – Measures for protection against overcurrent

- PN-IEC 60364-4-482:1999 Electrical installations in buildings – Protection for safety – Selection of protective measures depending on external influences – Fire protection

- PN-HD 60364-5-51:2011 Electrical installations in buildings – Part 5-51: Selection and erection of electrical equipment – General requirements

- PN-HD 60364-5-52:2011 Low-voltage electrical installations – Selection and erection of electrical equipment – Wiring systems

- PN-IEC 60364-5-523:2001 Electrical installations in buildings – Selection and erection of electrical equipment – Continuous current-carrying capacity of cables

- PN-IEC 60364-5-53:2000 Electrical installations in buildings – Selection and erection of electrical equipment – Switchgear and controlgear

- PN-HD 60364-5-534:2009 Low-voltage electrical installations – Selection and erection of electrical equipment – Isolation, switching, and control devices. Surge protection devices

- PN-IEC 60364-5-537:1999 Electrical installations in buildings – Selection and erection of electrical equipment – Switchgear and controlgear – Isolation and switching devices

- PN-HD 60364-5-54:2011 Low-voltage electrical installations – Part 5-54: Selection and erection of electrical equipment – Earthing, protective conductors, and protective bonding conductors

- PN-HD 60364-5-559:2012 Electrical installations in buildings – Selection and erection of electrical equipment – Other equipment – Luminaires and lighting installations

- PN-HD 60364-5-56:2010 Low-voltage electrical installations – Selection and erection of electrical equipment – Safety services

- PN-HD 60364-5-56:2010/A1:2012 Low-voltage electrical installations – Part 5-56: Selection and erection of electrical equipment – Safety services

- PN-HD 60364-6:2008 Low-voltage electrical installations – Part 6: Verification

Books and Journals

A good technical book can answer many questions and supplement your knowledge. I understand that nowadays, Google and AI like ChatGPT dominate, but if you want to be a good specialist in your field, it’s still worth reading books!

To begin, I’d like to recommend a few noteworthy titles.

Electric Machines – Antoni M. Plamitzer

An essential title in the private library of every automation designer. The book covers theoretical foundations and the principles of operation and construction of electric machines and transformers. Chapters 1 and 3 introduce the topic and provide general information about electric machines, while subsequent chapters focus on transformers, asynchronous machines, synchronous machines, DC machines, converters, and AC commutator machines. Antoni Marian Plamitzer was a Polish electrical engineer and academic affiliated with universities in Lviv, Gliwice, and Opole, and was one of the key founders of the polytechnics in Gliwice and Opole. This book will let you shine in discussions and confidently navigate topics related to electric machines.

Electrical Installations – Prof. Henryk Markiewicz

In the new edition, many aspects of electrical installations have been updated, new standards introduced, and emphasis placed on computer-aided electrical installation design. The book can be effectively used by engineers, electricians, electrotechnology specialists, electrical system designers, as well as technical students, and even vocational and technical school students.

Servo Drive Control Applications – Krzysztof Krzyżanowski

This textbook is intended for automation engineers involved in implementing control systems (PLC controllers) with advanced motion control functions. The author presents specific applications and technological solutions for them. He also describes challenges that engineers may encounter and offers effective solutions.

Electrotechnics: Electrical Installations and Industrial Electronics – Ernst Hornemann

This book presents topics in electrotechnics, industrial automation, and digital technology in an accessible way. Theoretical knowledge is enriched with many practical examples with thorough analysis, solutions, and conclusions. Each topic concludes with exercises for the reader to solve independently. Another book from this series, “Electrotechnics: Electrical Installations and Industrial Electronics – Exercises,” helps with selected tasks and consists of three sections: theory, exercises, and tasks. This publication has been recommended by the Central Commission for Higher and Secondary Education of the Polish Association of Electrical Engineers as a valuable and innovative title on the Polish market for students, teachers, and practical electricians.

Designing Electrical Installations in Industrial Facilities: Selected Issues – Waldemar Dołęga, Mirosław Kobusiński

This textbook serves as a compendium of knowledge on designing electrical installations in industrial facilities. Alongside the essential theoretical knowledge presented with specific design topics in mind, it provides detailed descriptions and analysis of selected design problems, including example calculations. This book is intended for electrical engineering students at technical universities, as well as for supervisory and maintenance staff in industrial plants, chief electricians, and professionals in the power sector.

The books above contain the most essential knowledge used by automation engineers. If you want to stay updated with the latest technical developments in the field, it’s also worth refreshing your knowledge by reading blogs and still-popular journals (in print). Here are a few:

Automation Components Applications

A magazine about industrial automation. It includes everything related to control, measurement, new components, and technologies. Each issue also features a technical-market report dedicated to a specific product or service segment. The magazine presents both components in specific applications and automation and measurement control systems, along with interviews with industry success stories and reports from major industry events.

Automation Monthly

The monthly “Automation” (ISSN 2392-1056) is a new publication initiative by the Łukasiewicz Research Network – Industrial Institute of Automation and Measurements (PIAP), created after a thorough market analysis. It brings together the needs of industry specialists with the expectations and possibilities of leading partners in the automation, robotics, and measurement sectors. Our readers include specialists from manufacturing companies, industrial firms, automation engineers, device and system designers, as well as maintenance departments. Additionally, senior and mid-level managers, production directors, and other personnel responsible for the technological aspect of production maintenance and development.

Electrotechnician and Automation Engineer

This magazine provides comprehensive analysis across the entire value chain of products, technologies, and services in the field of electrotechnics and industrial automation. It features new products, applications, and modern technologies that can enhance a company’s production potential. The magazine is targeted at engineers in industrial companies (electrotechnicians, automation engineers, planners, project engineers) and technical management staff.

Technical Documentation from Automation Manufacturers and Publications

No machine can be designed without the technical documentation of the devices that make up its components! I don’t know an automation engineer who doesn’t use the knowledge provided by manufacturers. Every designer has a base of their suppliers and valuable contacts among sales representatives and technical support. This way, projects are completed without errors and delivered ahead of schedule! Below, I will share some interesting publications from automation manufacturers that we use in our projects:

Professional Guide – Eaton

EATON’s Professional Guide is a collection of knowledge, definitions, and terms related to the automation industry.

Designer’s Guide, IEC Standards, Low-Voltage Range

This document aims to assist electrical consultants, electricians, and engineers in designing energy systems. Please explore the various sections to discover all the possibilities Eaton offers. We created this guide to facilitate collaboration with our clients and meet their diverse needs, both for new systems and existing ones. Eaton continually strives for success by developing technological innovations and creating next-generation solutions.

Application Book – Functional Safety in Practice – Wieland Electric

With the introduction of this safety application book, we aim to provide you with practical support in preparing and designing safety solutions for machinery. Example solutions for various safety applications are provided to aid you in the design process and offer the benefit of our experience. Wieland has been actively developing and operating in the market since 1910, positioning us as one of the leaders in this field. As a manufacturer of safety controllers and various types of safety sensors, Wieland has over 30 years of experience in this area. Our specialists in training and technical support are always available to share their knowledge and expertise with you.

Control Panels Compliant with IEC Standards and European Directives – Siemens

This reference guide focuses primarily on designing electrical equipment for machinery, specifically control panels and general-purpose distribution and control assemblies, as well as general electrical equipment for industrial machinery and systems in compliance with IEC 60204-1 and IEC 61439-1/-2 standards. The basic IEC 60364 standard also applies in many aspects and is therefore discussed here.

Effective Shielding Guide – WAGO

We have gathered and generalized our shared experiences and verified our approach with both theorists and practitioners. The result is this guide, which, dear readers, is now in your hands. Engineers designed it, and a graphic artist illustrated it. The outcome is a comic-style set of issues related to shielding, among other things, along with proposed solutions to specific problems.

These are just examples of the countless publications available from automation manufacturers. I also recommend reaching out to the technical support of a given automation manufacturer, as this ensures that your knowledge is up-to-date and verified by a specialist in a narrow field.

Conversations with Experts and Participation in Conferences/Trade Shows

It has long been known that conversations with industry professionals foster growth on many levels. You expand your technical vocabulary, validate your ideas, and learn about new solutions in the industry. Since I started working in automation, it has been a tradition of mine to regularly attend trade shows and conferences. At such events, you can build valuable contacts that will bear fruit in the future. More than once, I’ve come up with ideas for improving our machines during trade shows – all thanks to intensive discussions with partners. It’s worth taking care of your network!

Here are some events that I attend practically every year:

- Automaticon – The International Fair for Automation and Measurements, AUTOMATICON, has been the largest professional forum in Poland for 26 years, where producers, suppliers, and buyers of industrial automation come together. The fair offers exhibitors an excellent opportunity to showcase their achievements and gives visitors the chance to learn about new developments in automation, industrial measurements, and robotics.

- Warsaw Industry Week – Warsaw Industry Week is the International Fair of Innovative Industrial Solutions, held since 2016 at Ptak Warsaw Expo. The large space and broad range of thematic halls allow attendees to explore innovations and solutions across all key industrial sectors developing in Poland. Join us at Poland’s largest industrial trade fair!

Design Support Tools

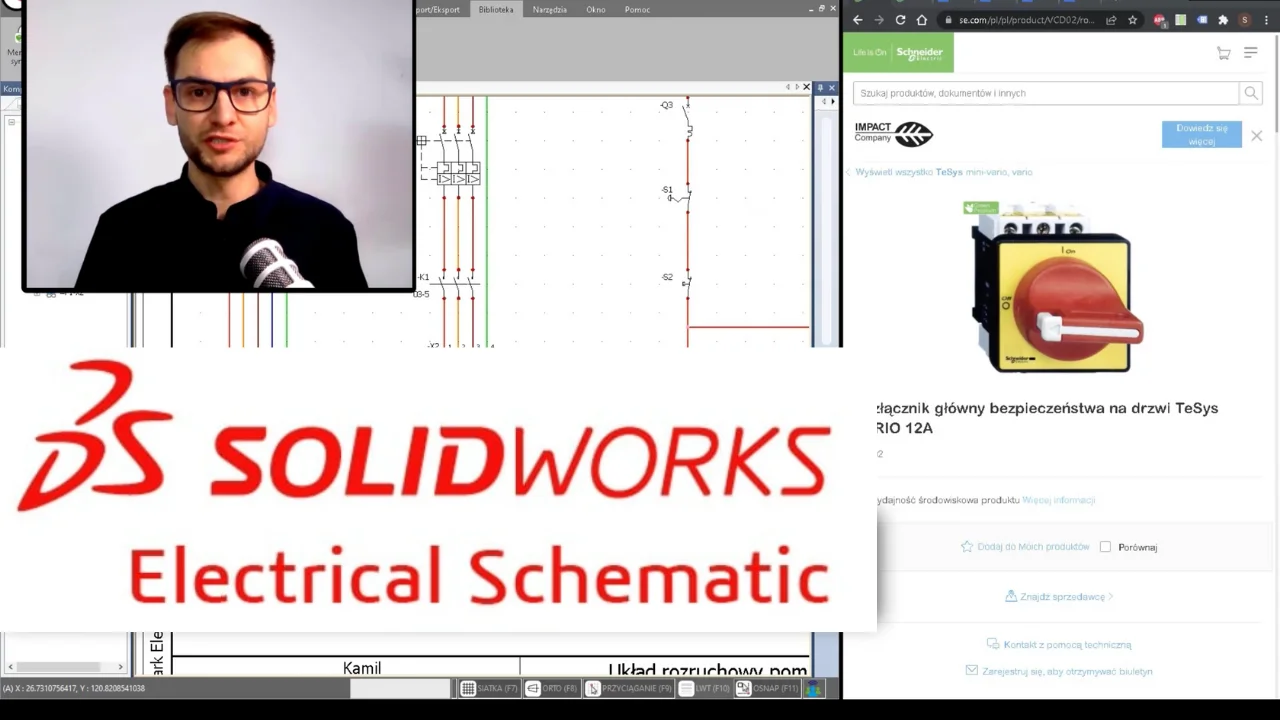

If you already have sufficient knowledge about design and selecting automation devices, the next step is choosing the appropriate design support tools. There are many free platforms available (with limited functionalities) as well as versatile “all-in-one” solutions. In our company, we use SolidWorks Electrical and several free online configurators.

SolidWorks Electrical

is both a program and a solution that simplifies drawing and designing systems and electrical diagrams through features like an intuitive interface that speeds up the design of the internal architecture of electrical circuits. The real-time bidirectional integration provided by SOLIDWORKS 3D CAD enables electrical and mechanical specialists in your company to work more efficiently. As a result, your company will experience fewer delays, increased consistency and standardization in projects, reduced costs, and faster product time to market. SolidWorks Electrical allows you to create installation designs, electrical harnesses using efficient routing and flattening tools, and automatically generate documentation. An interesting feature is that, based on the electrical diagram, you can generate a 3D control cabinet, which makes you feel like you’re on the production floor and helps you route wires correctly between devices.

A modern automation designer should also use free online configurators to speed up work! Most automation manufacturers provide such tools. The advantage is the ability to design online using a web browser. You have access to all components from a given manufacturer and can quickly design your solution. Here are a few examples:

WAGO Smart Designer

The Smart Designer online configurator, software for WAGO’s connection and automation technology products, provides users with access to created projects worldwide at any time without the need for installation.

TIA Selection Tool

Do you always need the optimal configuration for project planning? Of course! For your application, we offer the TIA Selection Tool, which supports all project planners, from beginners to experts. Detailed knowledge of the portfolio is not required. The TIA Selection Tool is available for download as a free desktop version or as a cloud version.

Rittal Configuration System

Quickly and correctly select enclosures and accessories. Easily design cutouts and holes with real-time 3D visualization of the configuration. Automatically generate order and production data as well as standards-compliant documentation. Directly transfer the configuration to EPLAN Pro Panel. Log into the online store for additional information on prices and availability.

In summary, it’s essential to start your automation project quickly and efficiently and see it through to completion. After that, you can collect your well-deserved payment 🙂 The right choice of tools will streamline your work, and the market will value it!

Thank you for reading! If you’re interested in learning more, explore our courses for in-depth training: Control Byte Courses.