Investigating Allen Bradley PLC Training Choices for Your Industrial Needs

Welcome to another insightful overview from ControlByte, the leading platform for learning the latest in industrial technologies. This guide explores the primary Allen Bradley PLC families by Rockwell Automation, helping you determine the right PLC for your project’s needs.

When selecting a PLC, it can be overwhelming to navigate the variety of options on the market, with each manufacturer offering various models suited to different applications. In this article, we’ll outline the different PLC families by Allen Bradley to make your decision easier. By the end, you’ll understand how each PLC family positions itself for different industrial needs and be ready to make a confident choice for your next automation project.

The Importance of Selecting the Appropriate PLC

Choosing the correct PLC for your automation project is not just about getting a machine to do the job; it’s about efficiency, reliability, and future scalability. A well-chosen PLC can support growth, allow flexibility, and ensure that your automation systems run smoothly and effectively. With so many options available, having a structured approach helps. By identifying which PLC family matches your project’s complexity and budget, you can avoid the common pitfalls of over-investing or under-utilizing features that aren’t needed.

Beginner Choices: Micro800 PLC Controllers

The Micro800 PLC family is Allen Bradley’s entry-level range, designed with small, standalone applications in mind. These PLCs are perfect for compact automation systems, offering a low-cost solution without unnecessary features. They are commonly used in applications that demand simple, direct control over one or two components, like conveyor belts, pumps, or basic machinery that doesn’t require sophisticated automation.

Micro800 PLCs are highly expandable through plug-in modules, allowing users to add extra inputs and outputs (I/O), communication protocols, or specific functionalities tailored to their needs. For instance, by adding communication modules, you can connect these PLCs to broader control systems or even integrate them into remote monitoring setups. This flexibility makes Micro800 PLCs versatile despite their entry-level positioning.

CompactLogix PLCs: Mid-Range Versatility (CompactLogix vs. Micro800)

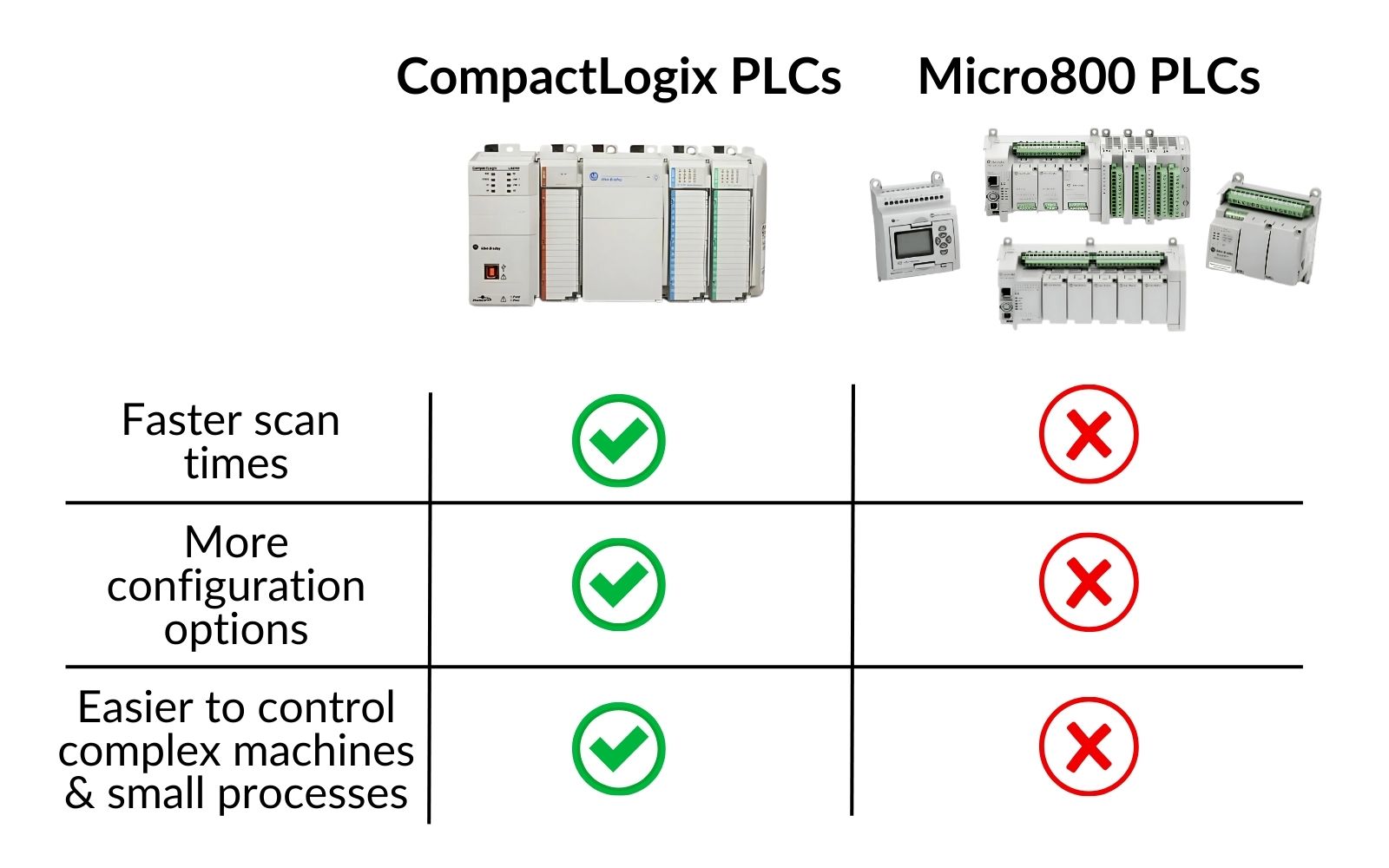

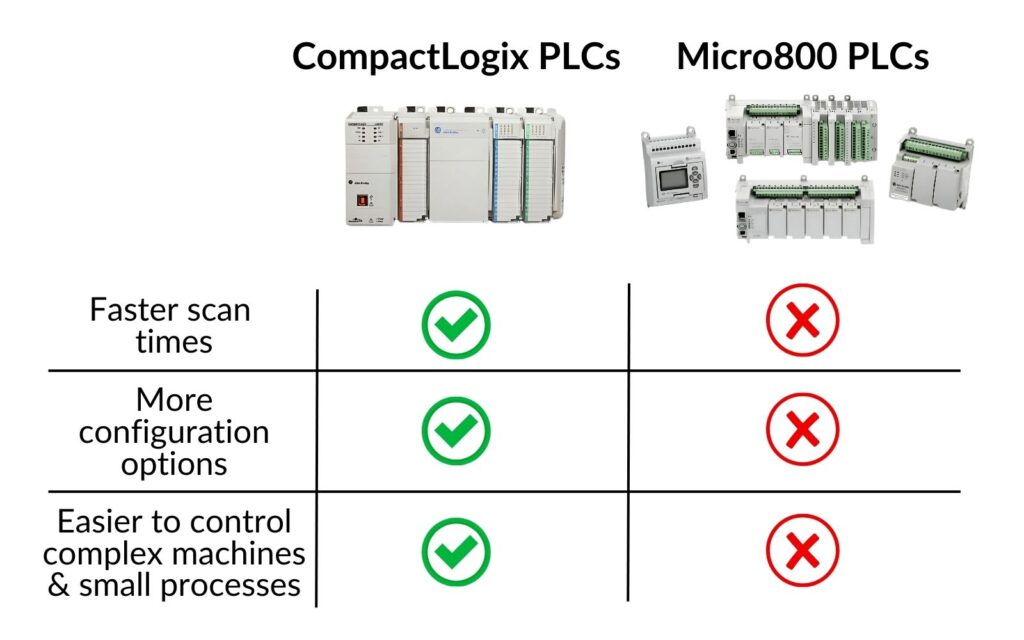

Allen Bradley’s CompactLogix PLCs serve as a versatile, mid-range choice, well-suited for projects that demand more processing power, faster scan times, and greater flexibility in I/O configurations. CompactLogix PLCs provide higher performance than the Micro800 series, making them ideal for applications with moderate complexity, like multi-device control or small automated production lines. For example, CompactLogix PLCs are often used in food processing or packaging industries, where precise timing, safety integration, and reliable control are crucial.

CompactLogix vs. Micro800: When comparing CompactLogix to Micro800, the main difference lies in their scope and power. CompactLogix PLCs are designed to handle more devices, support motion control, and integrate with a variety of advanced components like variable frequency drives (VFDs) and safety modules. This makes them a reliable choice for projects that need precise control across multiple devices.

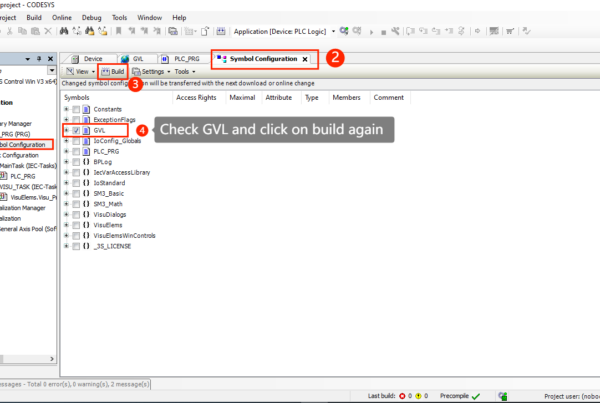

CompactLogix systems are programmed with Studio 5000 Logix Designer, a powerful software platform. Unlike Connected Components Workbench, Studio 5000 is packed with advanced features such as support for motion control and custom function blocks, which are helpful for designing complex automation solutions. Although Studio 5000 is not free, its capabilities make it an invaluable tool for automation professionals, allowing for streamlined configuration and advanced diagnostic functions.

ControlLogix Allen-Bradley PLCs: Advanced Management for Intricate Systems

At the top of the Allen Bradley range are the ControlLogix PLCs, which offer maximum flexibility, speed, and scalability for large-scale projects. These PLCs are designed for full production lines and complex processes, frequently used in industries where reliability and precision are paramount, such as pharmaceuticals, chemical processing, and large-scale manufacturing. ControlLogix PLCs provide minimal scan times, extensive I/O options, and the ability to control numerous devices simultaneously, even over long distances.

A standout feature of ControlLogix PLCs is their support for redundancy. This means that if one module or device fails, another can take over without disrupting the process, ensuring continuity in critical operations. Additionally, ControlLogix PLCs support communication protocols like HART (Highway Addressable Remote Transducer), which is commonly used in process industries for communicating with field devices like sensors and actuators. This advanced communication capability makes ControlLogix PLCs suitable for industries that require precise process control and integration with field devices.

A Look at the best plc programming automation Tools (studio 5000)

Both CompactLogix and ControlLogix PLCs are programmed using Studio 5000 Logix Designer, a feature-rich environment that supports advanced programming and debugging. With features like function block diagrams, ladder logic, and structured text, Studio 5000 offers flexibility in programming to suit different user preferences. While this software is a paid product, it is considered the gold standard for industrial programming, offering powerful tools for design, simulation, and diagnostics.

Further Factors to Consider When Choosing a PLC

While each Allen Bradley PLC family serves a unique role, other factors to consider in your selection process include environmental conditions, communication needs, and future scalability. For example, if your application requires resistance to high temperatures or vibration, some PLC families may offer ruggedized options. Additionally, if remote monitoring or connectivity with multiple PLCs is necessary, investing in a model with enhanced communication capabilities can simplify integration with broader control networks.

Final Thoughts

In this article, we’ve broken down the main Allen Bradley PLC families and their typical applications. The Micro800 series is ideal for simple, standalone applications and learners, CompactLogix fits mid-sized, flexible automation needs, and ControlLogix PLCs excel in complex, large-scale operations where advanced functionality and high reliability are essential.

Thank you for reading! If you’re interested in learning more, explore our courses for in-depth training: Control Byte Courses.