Hello! Welcome to our platform for learning PLC programming and automation. If you’re here, you’re likely a motivated individual eager to enter the world of programmable logic controllers (PLCs) and automation engineering, seeking an interesting, well-paying career. This guide will help you get started with PLC programming, even if you’re a complete beginner!

If you’re just starting out with automation and programming, you’re probably in one of these situations:

- I just graduated and am looking for my first job

- I’ve been working for a while and want to become a controls programmer and earn a good salary

- I got bored with my previous job and am looking for new challenges

- I’m a hobbyist, and programming robots and PLCs is awesome!

Believe me… I also started from scratch, and over a decade ago, getting started was much more challenging.

Now, it’s much easier as knowledge is more widely accessible.

Why Entering the World of Programmable Logic Controller (PLC) and Automation Programming is Challenging

Knowledge related to PLC programming, computer programming, and programmable logic controller software development is often protected by companies that produce machinery and industrial automation systems. Example PLC programs and programmable controllers are not widely shared on the internet. Automation software, like Siemens’ TIA Portal or Rockwell Automation’s programming platforms, is costly. Training courses on basic PLC programming concepts and programming devices are expensive, ranging around 900-1700 EUR. PLC hardware, including a starter PLC + HMI kit, costs around 750 EUR.

I remember my early days as an intern when I wanted to learn how to program PLCs. PLC programming courses were far beyond my reach—they cost more than two months’ salary! A senior automation engineer shared his training notes with me, which the company had provided—this was my starting point. I remember the copier working overtime as I copied over 1,000 pages of PLC programming materials. Working within the company, I also had access to professional PLC programs, giving me insights into industrial automation and the ladder logic programming used by the company. This experience was invaluable for my development as a PLC programmer.

These were the beginnings of my journey—extremely tedious but rewarding. Later, I was hired by an integrator company where I worked on various projects involving testing machines, technological systems, and robotic stations. I transformed my gained knowledge into the ControlByte training platform and launched my own company with a team of PLC engineers and programmers focused on executing custom automation projects.

Is There a Career Path to Becoming a Skilled PLC Programmer or Automation Engineer?

We’ve been providing training for automation professionals and aspiring PLC programmers since 2019. In the previous section, I outlined all the difficulties associated with entering the PLC and automation industry and securing a role as an automation engineer or PLC programmer.

Our mission is to help you acquire essential PLC programming skills, understand the fundamental concepts of PLC programming, and ultimately land your dream job in industrial automation.

Why PLC Automation Software (like Siemens’ TIA Portal) is Expensive—2,500 EUR+++

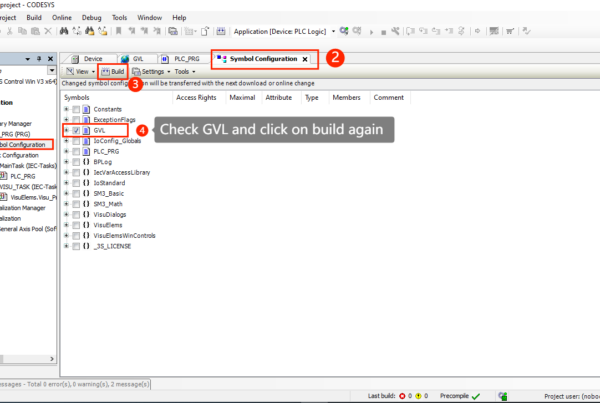

In our PLC training, we promote free versions of PLC programming software, which you can use to learn PLC programming without any additional costs. We recommend starting with Siemens’ TIA Portal or the Codesys environment—both popular platforms for learning and practicing PLC programming.

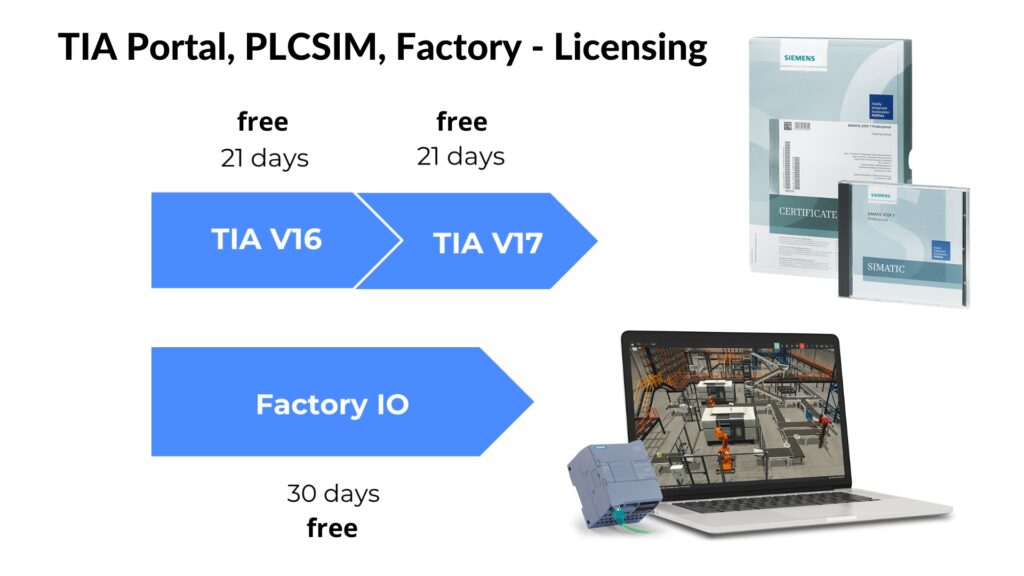

TIA Portal offers a trial version with a free 21-day license. These trial licenses are available for every TIA version—we use TIA V15.1, V16, and V17. In total, you can gain over 63 days of hands-on experience using this free PLC programming software.

Why Example PLC Programs and Programmable Logic Resources Aren’t Available Online

Companies protect their proprietary know-how, and software for machinery and automation systems is not freely shared as it is in the IT world. Access to PLC programming knowledge and automation software is often restricted.

In our courses, we provide PLC training that shares valuable knowledge gained from working with various companies, following global standards from Siemens, PLCopen, and OMAC (Organization for Machine Automation and Control).

We also collaborate with leading manufacturers and distributors of automation hardware—such as Siemens, Lenze, Turck, Wieland, and Finder. These companies supply us with programming libraries and technical resources essential for practical PLC programming and industrial automation education.

The High Cost of Learning PLC Programming: Why Traditional Training is 900-1700 EUR

Traditional classroom training for PLC programming is standard in the market but has several disadvantages:

- It is expensive—900-1700 EUR.

- It requires a full week off from work/school.

- Travel, accommodation, and meals for the week are required.

- The pace of learning does not depend on you—if you get lost, you’re out of luck.

The total cost of traditional classroom training can reach up to 2,500EUR!

When we created the ControlByte platform, we aimed to help those for whom attending in-person training is unattainable.

We established a new standard in the world of PLC programming education—online training with instructor support.

Currently, there are several thousand users on our platform!

Why Thousands Choose Online Courses to Learn PLC Programming and Ladder Logic

- The cost is much lower than in-person training (only 30% of the price of traditional training).

- You can complete the projects at your own pace.

- You can test your code in the virtual Factory IO environment.

- You don’t need physical equipment to learn PLC programming—all you need is a good PLC and HMI simulator.

- You have lifetime access to the materials, allowing you to revisit them and use project templates in your work!

Overcoming Expensive Hardware Costs for Learning PLC and HMI SystemsN

In our training, we use PLC and HMI simulators. For over 10 years, Siemens has been refining simulators for their hardware. Now you can run the PLC simulator and Factory IO virtual factory software on your PC and feel like you’re commissioning real equipment in an actual factory.

How to Master Ladder Logic and PLC Programming in a Month: Key Tips for Beginners

Now listen up! I have some clear tips on how to learn automation programming from scratch without the need for physical hardware. Don’t waste time—focus on strategies that work. In my opinion, you should start by choosing a mentor (an experienced colleague), someone well-versed in automation and control systems. Where can you find such individuals? Most likely, they’ll be in your company, but first, you need to get there. That’s why there’s another option: learn from experts online through structured automation courses. This way, you save time, leading to faster results!

Start programming today using a simulator! You don’t need costly hardware to write simple ladder logic (LAD) programs. You can start learning as soon as you install the necessary software tools on your computer. Which projects should you tackle first? Check out the next sections for recommendations!

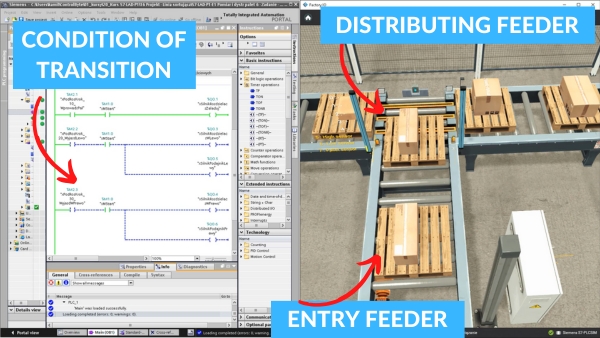

PLC Project Example: Pallet Measurement and Distribution Using Ladder Logic

In this brief entry, I want to focus on basic automation projects that can be completed quickly while learning logic programming in LAD. The first example is a setup with three conveyors that measure the height of packages on a pallet and manage their distribution. For this project, specific sensors and a distribution feeder are utilized. Although it may appear simple, understanding the design principles for sequences is essential.

To manage these tasks, use setting (SET) and resetting (RESET) coils. This method helps you follow the sequence steps and activate the required devices along your line. LAD allows you to organize the sequence into networks, creating a structured project. Different networks handle the START/STOP/PAUSE system, manual and automatic modes, as well as alarm systems.

This project uses the free version of Factory I/O software, a 3D simulation tool, enabling communication with Siemens control systems through TIA Portal. All that’s needed is to call the correct function block and transfer the necessary variables. Completing this project will bring great satisfaction and demonstrate how LAD can be applied in real-world scenarios.

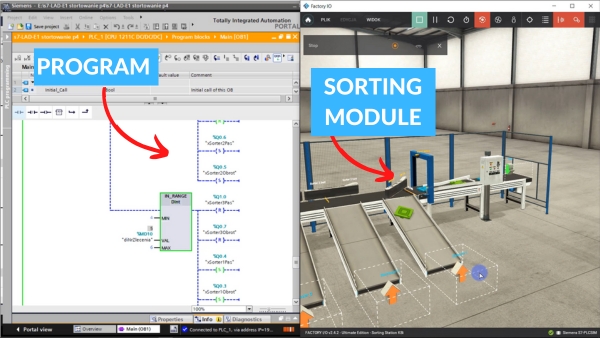

Product Sorting Line Project: Learning PLC Programming and Control System Basics

Another commonly encountered object in factories is product sorting lines. In this type of exercise, you will learn how to use LAD to control a vision sensor and individual sorters. Every automation engineer must know what a control panel looks like. This is where you can find various types of buttons, settings, and displays. You will learn the construction of the control panel in the simulator and understand which signals your PLC processes.

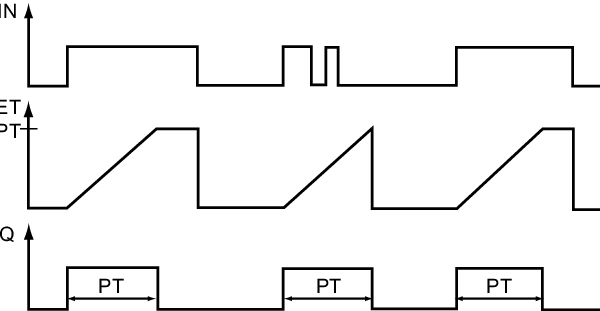

The simplest LAD program consists of a normally open contact -| |- and a coil -( )-. However, if you want to test how such a program works, you need to refer to the signals from buttons or other input/output devices connected to the PLC. For example, you refer to a signal from a START button. If that button is pressed, you activate a feeder connected to a PLC output.

These basics are enough to start developing program logic! Really, contacts and coils, along with learned functions and function blocks, are all you need.

In the sorting project, an important function is IN_RANGE, which checks if a given product is within the appropriate range. The product is read by the vision sensor. Summing up, LAD basics will give you quick results in the form of a completed project that you can showcase in your CV or present to your boss during a salary negotiation.

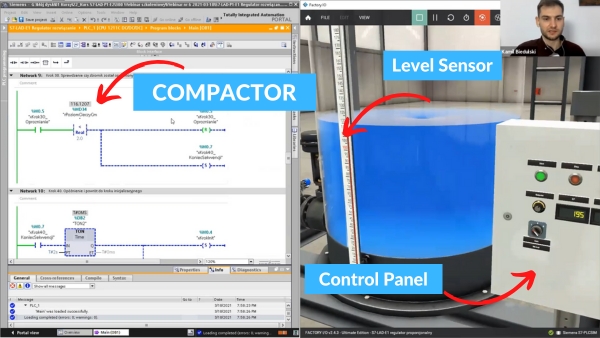

Designing a Proportional Controller for Industrial Automation: Liquid Tank Project

Besides writing machine sequences, LAD is also great for handling industrial processes. One interesting program involves writing a simple PI controller to manage the liquid level in a tank. You will perform value conversions from level sensors and settings and appropriately tune the PI controller.

In this exercise, you will learn about analog measurements. Processing these values in LAD will be quick and easy. It is worth using comparison operators to enable/disable the controller. The controller’s operation can follow different scenarios. For example, you may need to consider filling and emptying sequences of the tank. However, you have a tool that makes your job easier. You can program in LAD!

PLC Program and HMI Design for a 2D Manipulator: A Practical Guide

Every machine has an HMI panel. It’s crucial that you can design visualizations and link your LAD logic with visualization tags. My project suggestion is an HMI panel for a 2D manipulator.

The station consists of two conveyors and an XY manipulator. Your task is to write a program for stacking products in a crate. The manipulator picks up products from one line and places them one on top of the other. Once again, you need to think about writing a few LAD networks to handle manual/auto modes and start/stop/pause states. Ready-made visualization templates, which you can download from our platform, can make this easier. We use such visualizations in projects for our clients.

Remember that your goal is to write a program that satisfies the client. Usually, this means choosing a language required at the site. It has to be easy to analyze for maintenance and service personnel. From our experience, LAD is a good choice that clients tend to appreciate!

This was an introductory article where you learned what LAD is and what projects you can complete using a simulator. A comprehensive introduction to LAD can be found in the video below!

Thank you for reading! If you’re interested in learning more, explore our courses for in-depth training: Control Byte Courses.