SINAMICS S120: The Cornerstone of High-Performance Engineering

The SINAMICS S120 drive system, a cornerstone of the SINAMICS converter lineup, is crafted for high-performance roles in machine and plant engineering. Its modular and scalable architecture makes SINAMICS S120 the optimal choice for addressing growing demands for enhanced capabilities and operational flexibility. This system simplifies custom machine designs and accelerates the deployment of specialized drive solutions.

Optimized Motion Control and Versatile Applications with SINAMICS S120

In today’s competitive manufacturing landscape, businesses need machines that combine cost-efficiency with exceptional productivity. The SINAMICS S120 drive system delivers on both fronts. Its straightforward configuration reduces project timelines, while its dynamic performance and precision facilitate faster cycle times, maximizing productivity.

Applications of SINAMICS S120 Across Industries

The SINAMICS S120 drive system elevates machine performance in a variety of industrial applications. Whether handling continuous processes or high-speed cyclic operations, it’s a perfect fit for:

- Packaging equipment

- Plastic manufacturing machines

- Textile machinery

- Printing presses

- Paper production systems

- Woodworking tools

- Cranes and hoists

- Assembly and handling systems

- Machine tools

- Rolling mills

- Test benches

- Renewable energy systems

Customization with the Modular SINAMICS S120 Design

The SINAMICS S120 modular system allows seamless integration of power and control components, making it versatile for single-drive setups as well as advanced multi-axis configurations. This adaptability ensures it meets diverse engineering requirements.

Advanced Control and Performance with SINAMICS S120

Advanced Control Intelligence in SINAMICS S120

At the heart of SINAMICS S120 are Control Units that manage closed-loop control processes. These units support various operational modes, including Vector, Servo, and V/f, delivering precise speed, torque, and position control across all axes.

Tailored Performance Modes with SINAMICS S120

- Vector Control: Ideal for applications involving continuous material flows, such as wire-drawing machines, paper production, hoists, centrifuges, and marine drives.

- Servo Control: Perfect for cyclic operations demanding precision and dynamic positioning, including textile machinery, packaging equipment, and machine tools.

Key Features Driving SINAMICS S120 Efficiency

The SINAMICS S120 system is equipped with innovative features that optimize both performance and energy efficiency:

- High-precision control of speed, torque, and positioning

- Automatic restart functions after power interruptions

- BICO technology for easy adaptation to specific operating environments

- Integrated safety functions for enhanced compliance and efficiency

- Energy-efficient infeed and regenerative feedback for braking energy recovery and supply stability

Simplifying Connectivity with SINAMICS S120 DRIVE-CLiQ

The SINAMICS S120 system’s components are interconnected via DRIVE-CLiQ, a standardized digital interface. This simplifies integration, reduces the variety of required parts, and lowers storage costs. Converter boards also enable compatibility with third-party motors.

Effortless Commissioning with SINAMICS S120

Each component in the SINAMICS S120 system features an electronic type plate. These plates enable automatic identification through DRIVE-CLiQ, eliminating the need for manual data input during setup or component replacement. This ensures error-free and efficient commissioning.

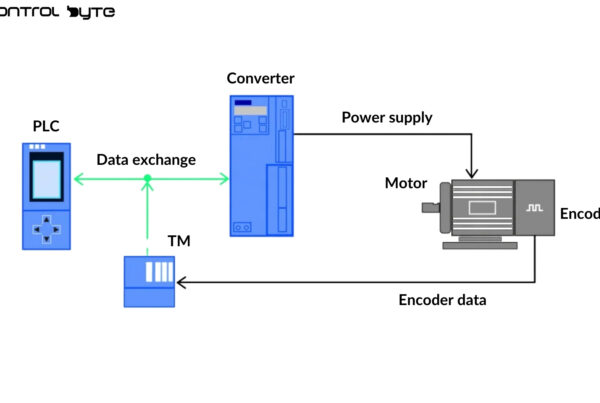

Modular Architecture of SINAMICS S120

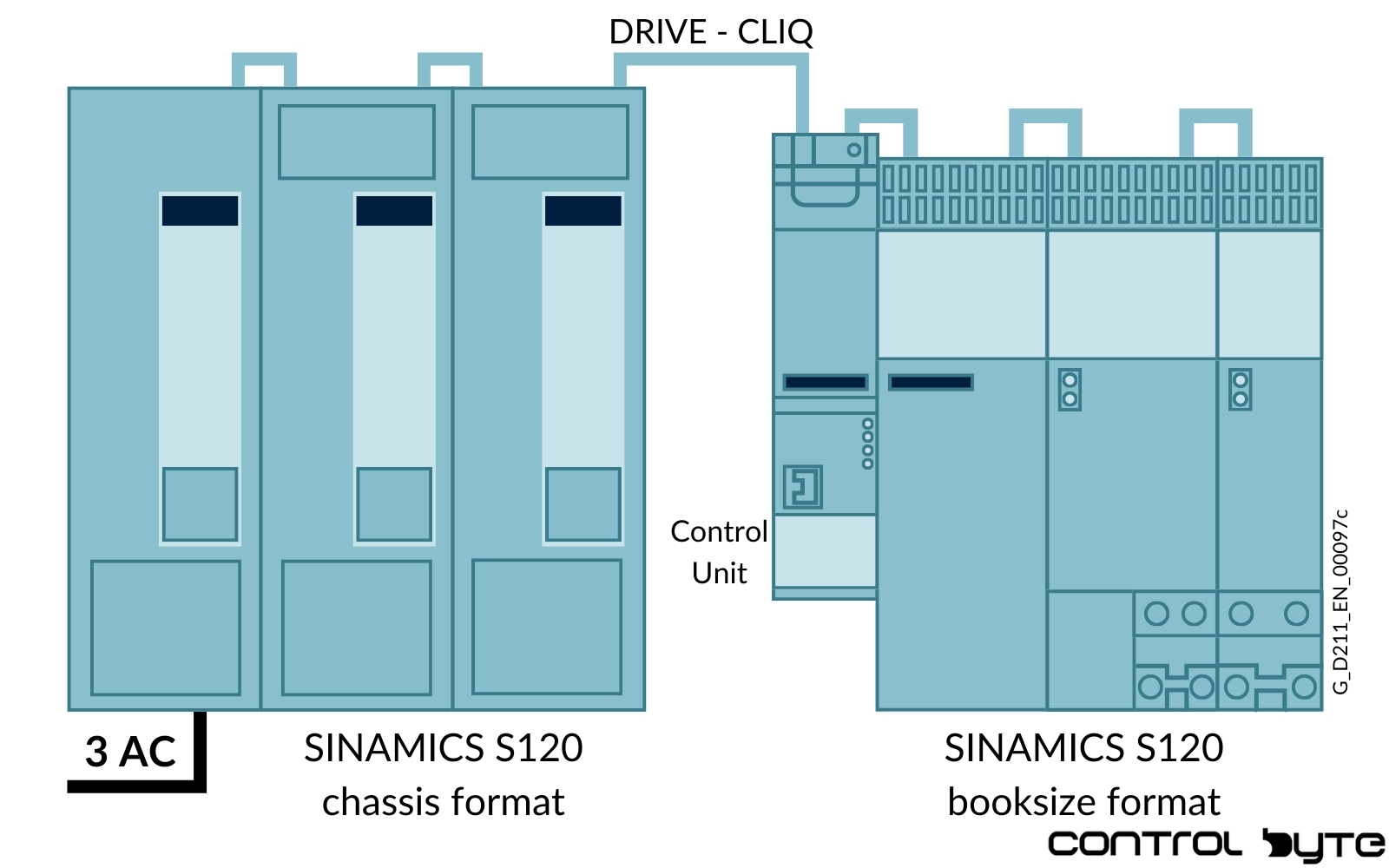

The SINAMICS S120 system features a scalable modular architecture with DC/AC units available in compact booksize, booksize, and chassis formats. Core drive intelligence resides in Control Units that manage closed-loop control, drive-related I/Os, and interfaces like PROFIBUS DP or PROFINET.

- Line Modules: Provide central energy supply, with optional infeed and regenerative feedback for consistent DC link voltage and enhanced power stability.

- Motor Modules: Supply energy to motors via the DC link.

- AC/AC Units: Combine infeed and motor power functions into a single Power Module, available in blocksize and chassis configurations.

Flexible Combination of SINAMICS S120 Formats

The SINAMICS S120 system’s different formats can be freely combined, offering unparalleled adaptability. Thanks to the DRIVE-CLiQ interface, components like Line Modules in chassis format can seamlessly pair with Motor Modules in booksize format. This flexibility supports the creation of multi-axis systems with high total output tailored to specific requirements.ports the creation of multi-axis systems with high total output tailored to specific requirements.

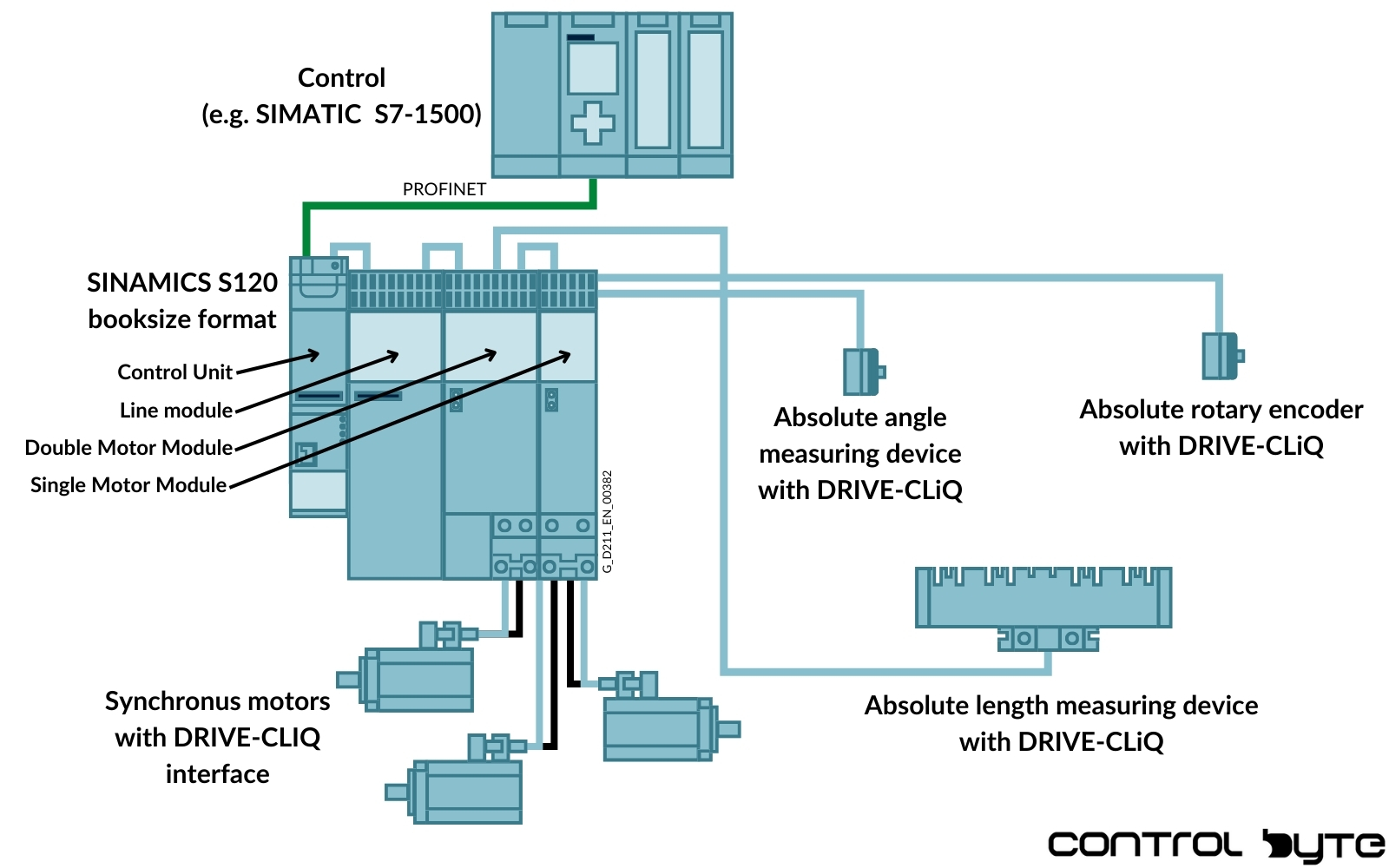

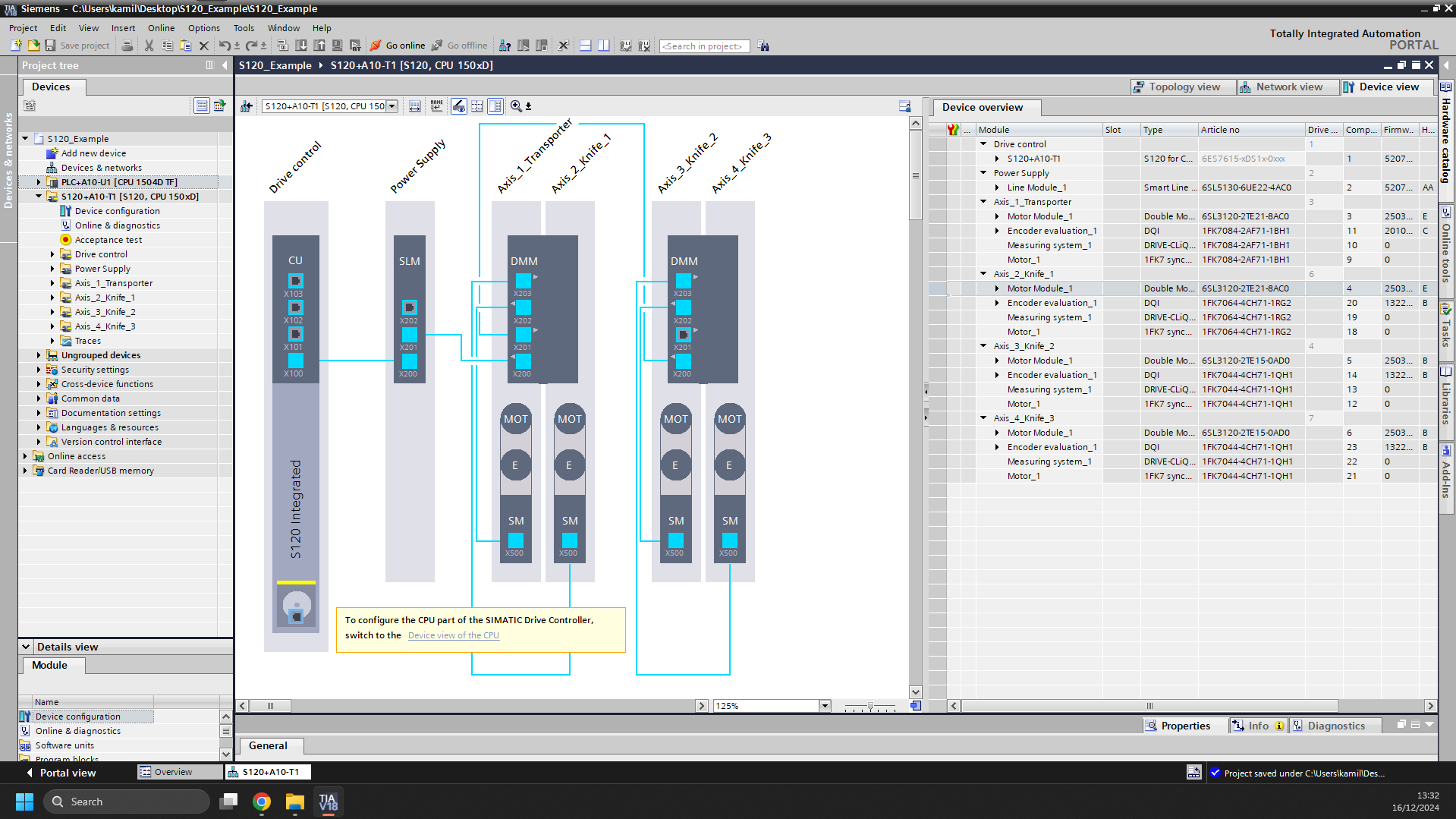

The diagram shows the configuration of the SINAMICS S120 drive system, including the central control unit, infeed (line module), and motor modules (inverters). The system integrates motors via DRIVE-CLiQ and supports communication with higher-level systems through PROFINET and PROFIBUS protocols. Digital and analog I/O modules expand connectivity options, making the setup suitable for precise motion control and versatile industrial applications.

The diagram illustrates the configuration of the SINAMICS S120 drive system in a booksize format, integrated with the SIMATIC S7-1500 controller via the PROFINET protocol. The system uses the DRIVE-CLiQ interface to connect power modules, synchronous motors, and measuring devices such as encoders and sensors for absolute length and angle measurement. This setup enables precise motion control, fast data processing, and flexible integration into advanced industrial applications requiring high performance and reliability.

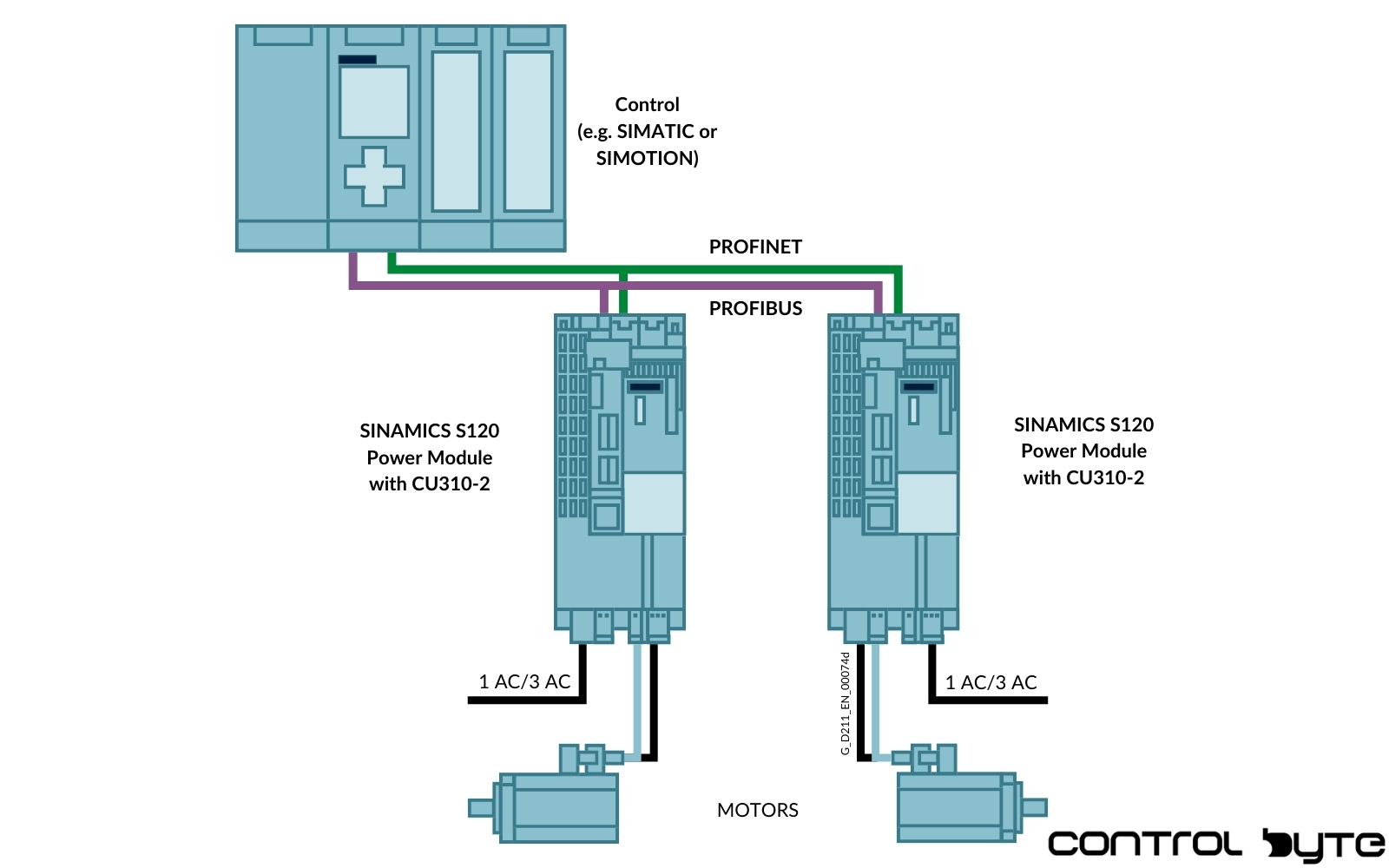

The diagram illustrates a configuration of SINAMICS S120 Power Modules with integrated CU310-2 control units. Each module is directly connected to motors and communicates with the higher-level control system (e.g., SIMATIC or SIMOTION) via PROFINET and PROFIBUS protocols. This setup enables precise, standalone motor control while maintaining seamless integration with industrial automation systems.

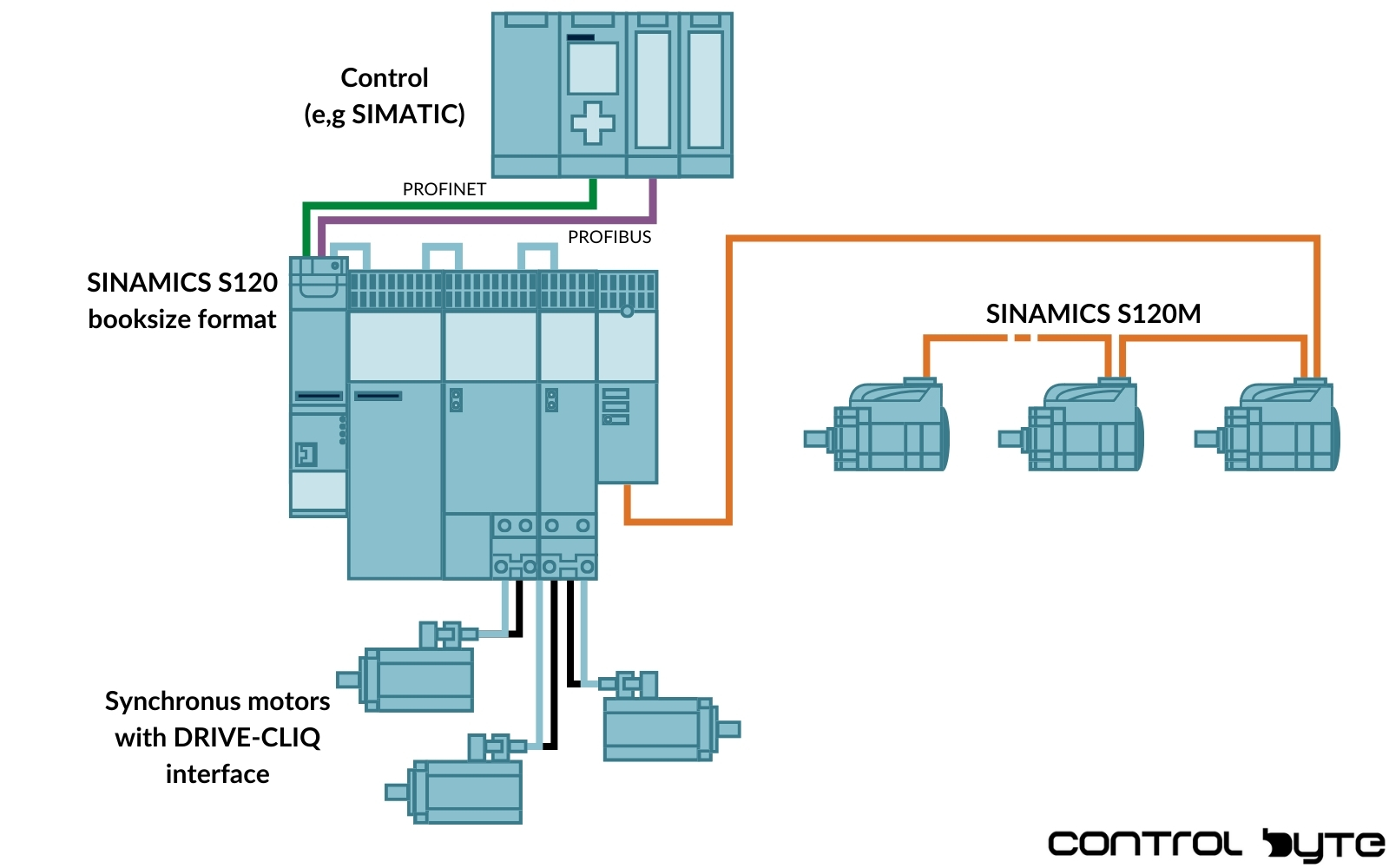

The diagram demonstrates the integration of SINAMICS S120 in booksize format with synchronous motors via DRIVE-CLiQ and additional SINAMICS S120M modules. The system communicates with a higher-level control unit, such as SIMATIC, using PROFINET and PROFIBUS protocols. This configuration ensures precise motor control and scalability for advanced industrial automation applications.

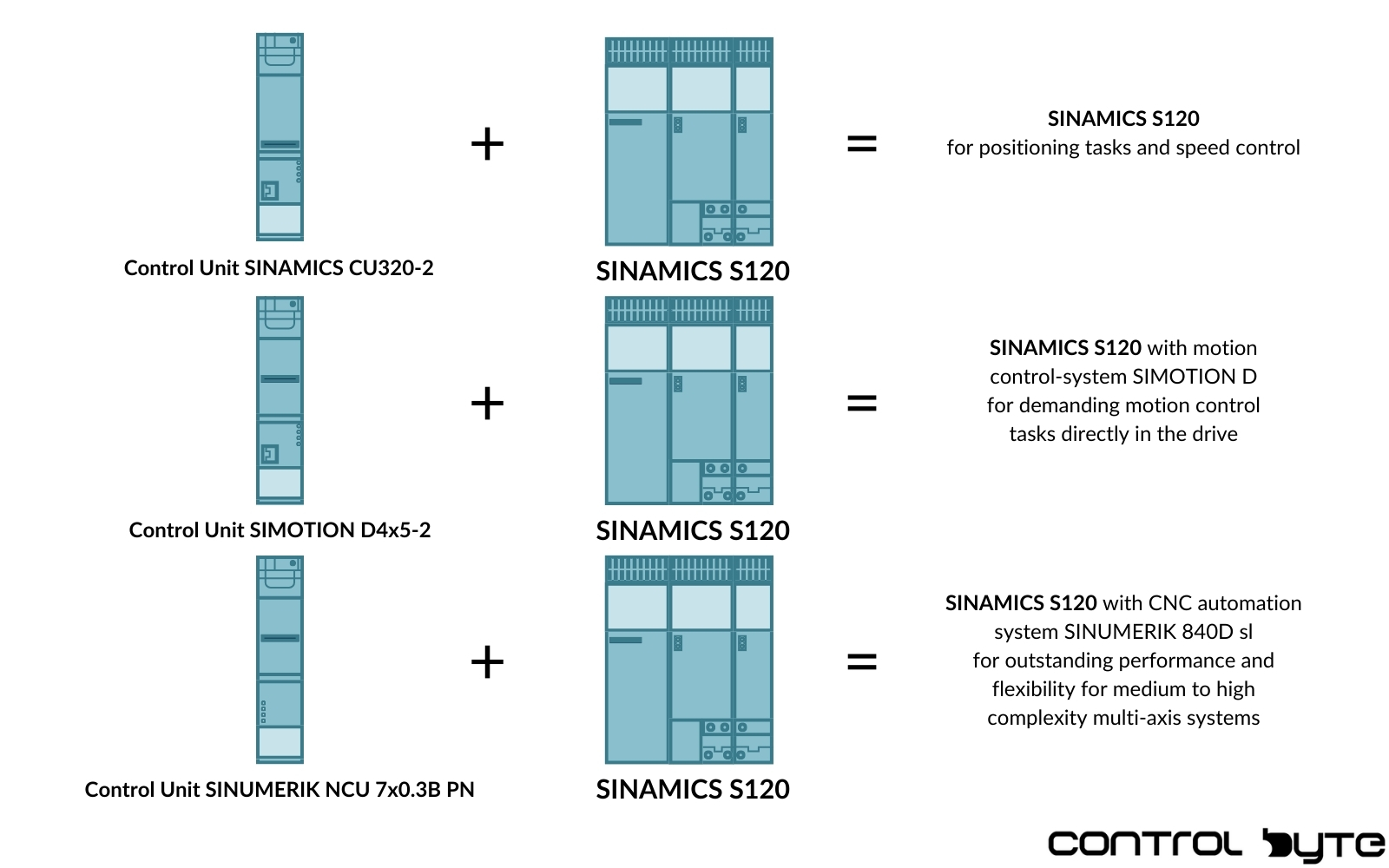

Select Control Unit for SINAMICS S120

The SINAMICS S120 drive system scales effortlessly to meet diverse performance and technological demands. For more sophisticated requirements, the Control Unit can be replaced by advanced drive-based motion controllers such as:

- SINUMERIK: Optimized for machine tools.

- SIMOTION D: Designed for production machinery and plant engineering.

Furthermore, SINAMICS S120 can integrate smoothly with higher-level SIMATIC S7 systems, leveraging their built-in technological capabilities for enhanced performance.

Motion Control Functions and Totally Integrated Automation (TIA)

Scalable Motion Control Functions

As a key element of Siemens’ Totally Integrated Automation (TIA) platform, SINAMICS S120 drives industry-specific solutions with precision. The TIA approach provides:

- Reduced operational life-cycle costs

- Faster time-to-market

- Enhanced productivity and secure investments

Simplified Automation with TIA

SINAMICS S120, in combination with SIMATIC, SIMOTION, and SINUMERIK, forms a cohesive part of the TIA ecosystem. By utilizing the STARTER commissioning tool, engineers can:

- Parameterize and program all automation components

- Achieve consistent data management

- Simplify project archiving and system-wide configuration

Advanced Communication with PROFINET and PROFIBUS

PROFINET for High Performance

All SINAMICS S120 variants support PROFINET, the Ethernet-based fieldbus of the TIA system. Key features include:

- Rapid data transfer with PROFINET IO using IRT or RT

- Seamless integration into top-tier multi-axis applications

- Compatibility with standard IT protocols (TCP/IP) for transmitting diagnostic and operational data to higher systems

This capability ensures SINAMICS S120 can connect effortlessly with factory IT networks for improved performance and data exchange.

PROFIBUS for Robust Networking

The SINAMICS S120 also supports PROFIBUS DP, enabling:

- High-performance communication across HMIs, controls, drives, and I/O devices

- Reliable system-wide integration for varied automation needs

This dual communication protocol support ensures the SINAMICS S120 remains versatile and adaptable for diverse industrial applications.

Example Configuration SINAMICS S120

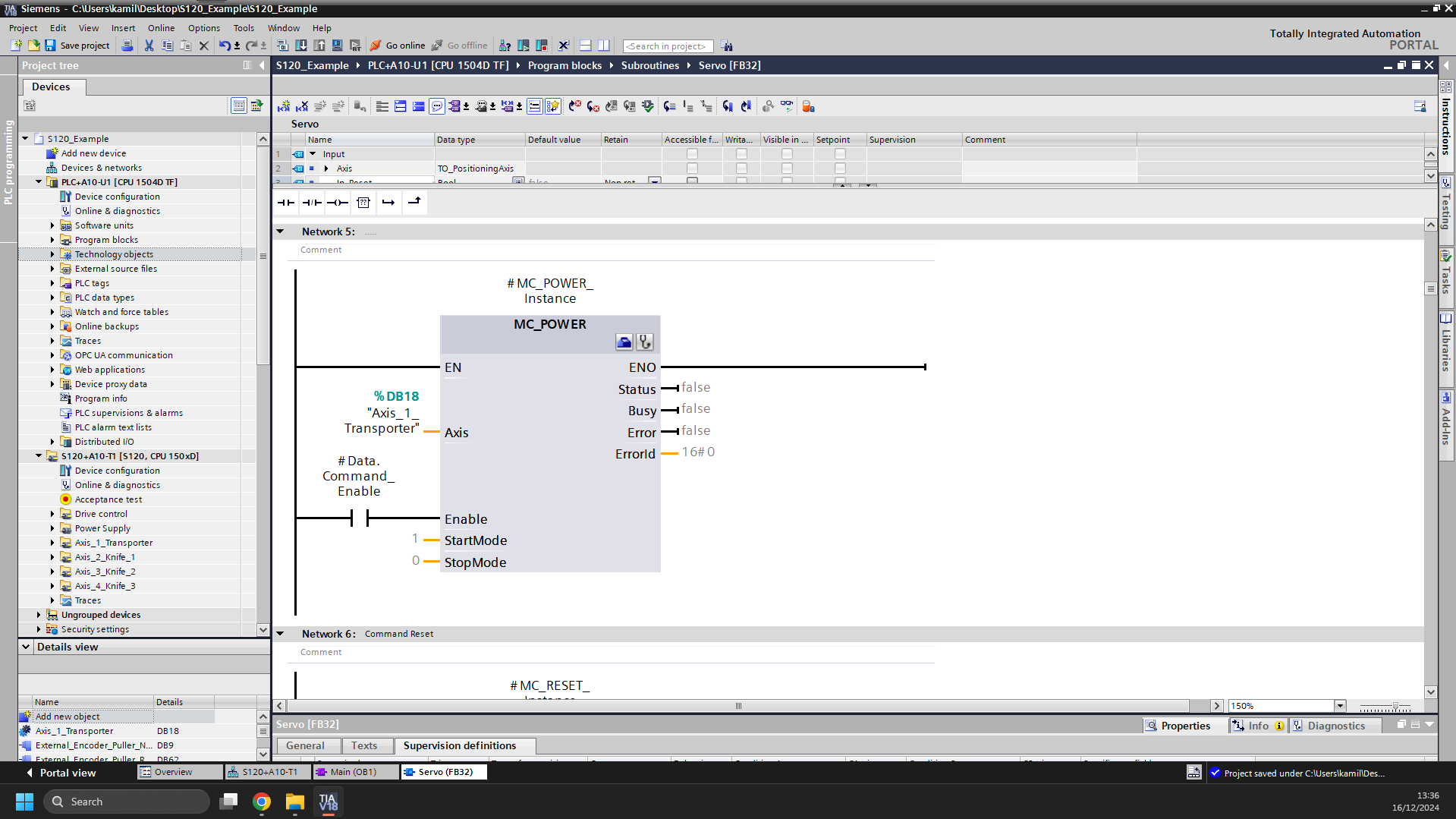

Follow these steps to configure SINAMICS S120 in TIA Portal:

- Add the PLC Controller: Select a compatible controller, such as SIMATIC S7-1500.

- Configure SINAMICS S120 in HW Config:

- Add the control unit (e.g., CU320-2) and power modules.

- Virtually connect the components according to the physical setup.

- Create a Technological Object: Set up an “Axis” object in TIA Portal for axis management.

- Program Motion Sequences: Use pre-configured PLCopen blocks for motion control.

- Testing and Commissioning: Simulate and test the configuration in TIA Portal.

Summary

The SINAMICS S120 drive system offers unmatched flexibility, scalability, and precision for industrial automation. Through seamless integration with control systems like SIMATIC and SIMOTION, advanced communication via PROFINET and PROFIBUS, and compatibility with DRIVE-CLiQ-enabled motors and modules, it enables efficient and reliable motion control. Its modular architecture and diverse configurations make it the ideal solution for a wide range of applications, from single-axis setups to complex multi-axis systems, ensuring optimal performance and adaptability in modern industrial environments.