SINAMICS S120 Double MOMO 5A/5A (6SL3120-2TE15-0AD0) is an advanced inverter from Siemens’ SINAMICS S120 series, designed for applications requiring high precision, dynamics, and flexibility. With its capability to handle 5A/5A currents, this model is an ideal choice for a wide range of advanced industrial applications.

Technical Specifications: SINAMICS S120 Double MOMO 5A/5A

| Parameter | Value |

|---|---|

| Article Number | 6SL3120-2TE15-0AD0 |

| Product Series | SINAMICS S120 |

| Module Type | Double Motor Module |

| Input Voltage | DC 600V |

| Output Voltage | 3AC 400V, 5A/5A |

| Frame Size | Booksize D-Type |

| Cooling | Internal Air Cooling |

| Optimized Pulse | Optimized Pulse Sampling |

| Safety Features | Extended Safety Integrated Functions (incl. STO) |

| Communication | DRIVE-CLiQ |

| Additional Equipment | DRIVE-CLiQ Cable Included |

Purpose and Functionality of SINAMICS S120 Double MOMO 5A/5A

The SINAMICS S120 Double MOMO 5A/5A (6SL3120-2TE15-0AD0) is designed to precisely control various types of motors, including synchronous, induction, and servo motors. Key features include:

- Modular Design: Flexibility to adapt the system to specific application requirements.

- Multi-Axis Control: Enables simultaneous control of multiple motors, essential for synchronized motion applications.

- Integrated Safety Features: Safety Integrated technology, such as STO (Safe Torque Off), ensures safe system operation.

- Precise Regulation: Accurate torque, speed, and position control for motors.

Where Can SINAMICS S120 Double MOMO 5A/5A Be Used?

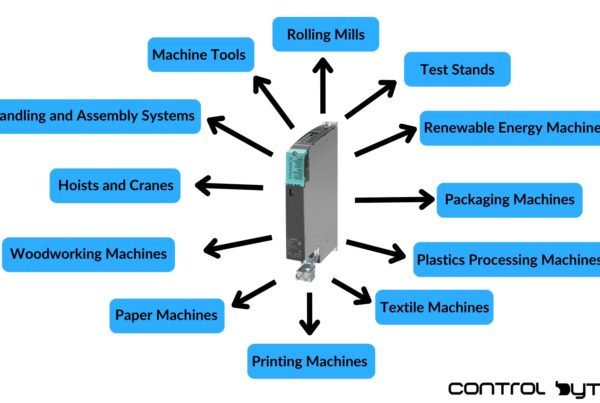

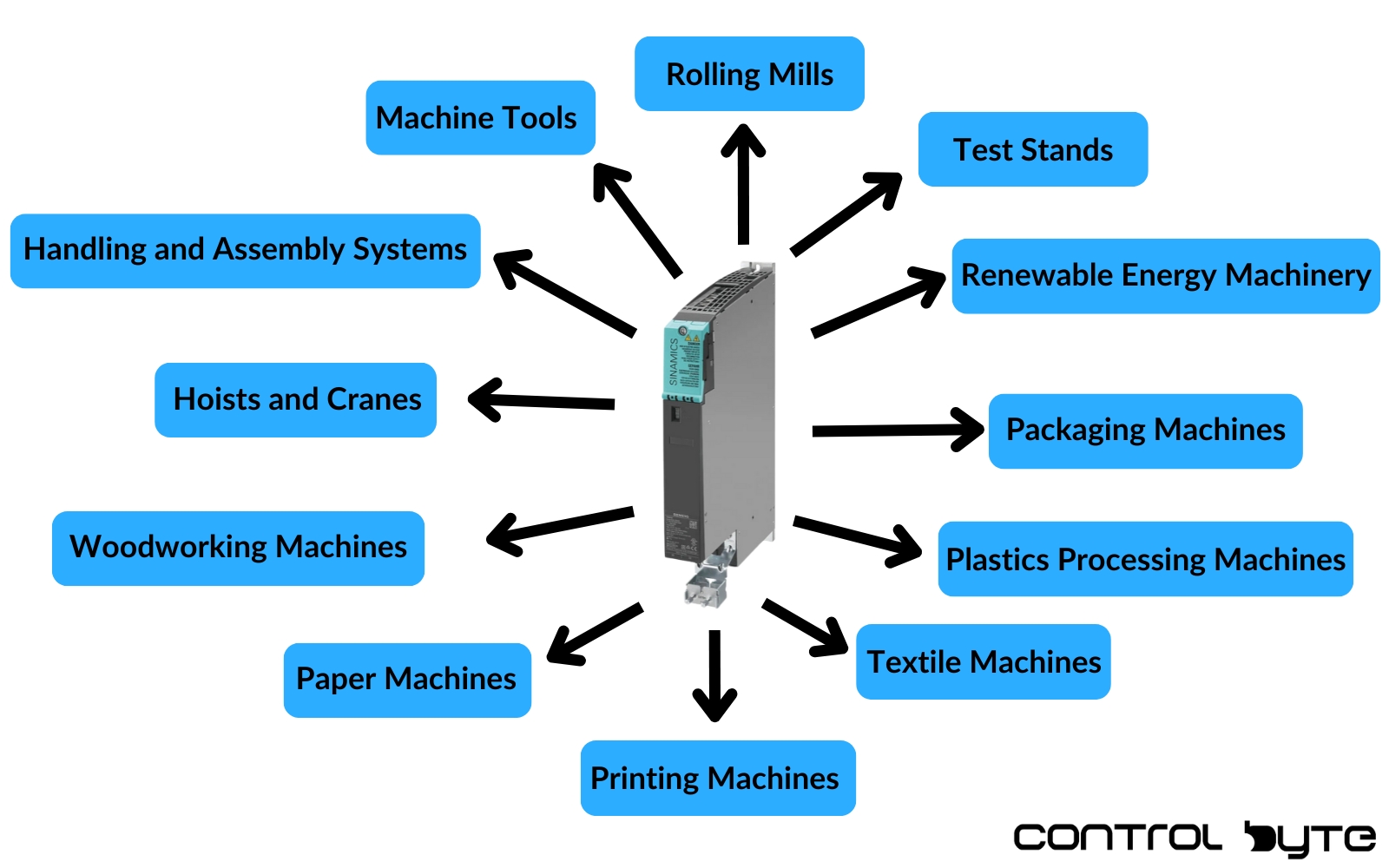

The SINAMICS S120 Double MOMO 5A/5A (6SL3120-2TE15-0AD0) is suitable for industries and applications that demand high precision and flexibility, including:

- Packaging Machines: Synchronization and motion control in packaging equipment.

- Plastics Processing Machines: Managing precise plastic processing operations.

- Textile Machines: Controlling weaving and spinning processes with precision.

- Printing Machines: Accurate control and synchronization in printing systems.

- Paper Machines: Managing complex paper production processes.

- Woodworking Machines: Control of advanced woodworking production lines.

- Hoists and Cranes: Precise control of lifting and transporting loads.

- Handling and Assembly Systems: Automation of industrial manufacturing processes.

- Machine Tools: Dynamic and multi-axis control for CNC machines.

- Rolling Mills: Control of rolling processes in metal production.

- Test Stands: Precision control in research and testing applications.

- Renewable Energy Machinery: Control of wind turbines and other renewable energy systems.

What Do You Need to Use SINAMICS S120 Double MOMO 5A/5A?

To fully utilize the SINAMICS S120 Double MOMO 5A/5A (6SL3120-2TE15-0AD0), the following components are required depending on the application’s needs:

- Control Unit (CU):

- CU320-2: For standard positioning and speed control tasks.

- SIMOTION D (e.g., D4x5-2): For demanding motion control tasks directly within the drive.

- SINUMERIK NCU 7×0.3B PN: Ideal for CNC systems such as SINUMERIK 840D sl, providing outstanding performance for medium-to-high complexity multi-axis applications.

- Power Module: SINAMICS S120 Double MOMO inverter, which works seamlessly with the selected control unit.

- Application-Specific Solutions:

- CNC Systems: Use SINUMERIK NCU for machine tools and multi-axis machines.

- Advanced Motion Control: Use SIMOTION D for production engineering.

- Standard Speed and Position Control: Use CU320-2 for simpler applications.

Documentation and Technical Support

To take full advantage of the SINAMICS S120 Double MOMO 5A/5A (6SL3120-2TE15-0AD0), refer to the following documentation:

- SINAMICS S120 Documentation: Link to Documentation

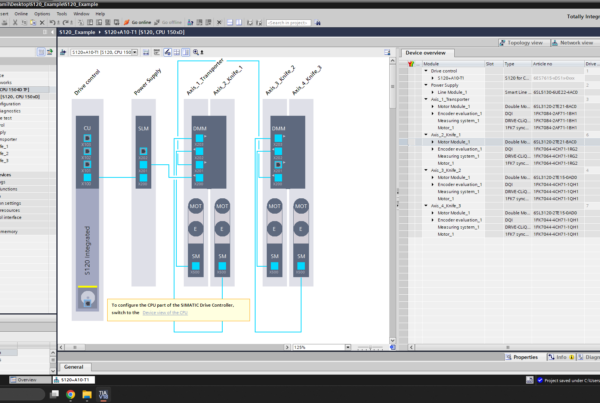

Example Configuration in TIA Portal

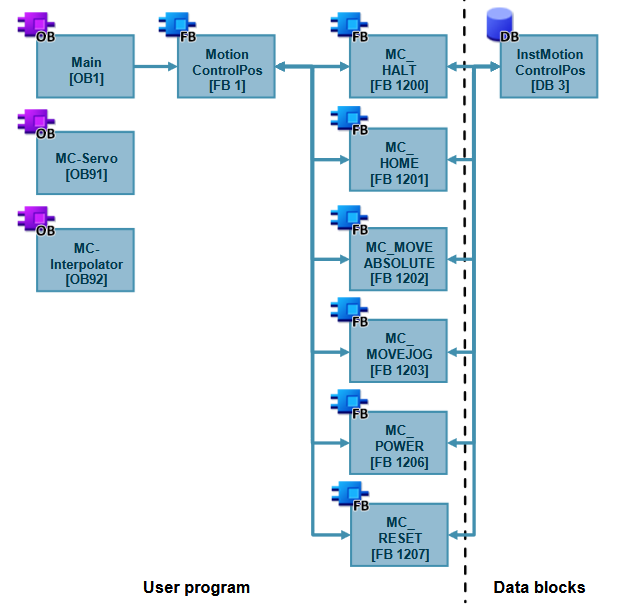

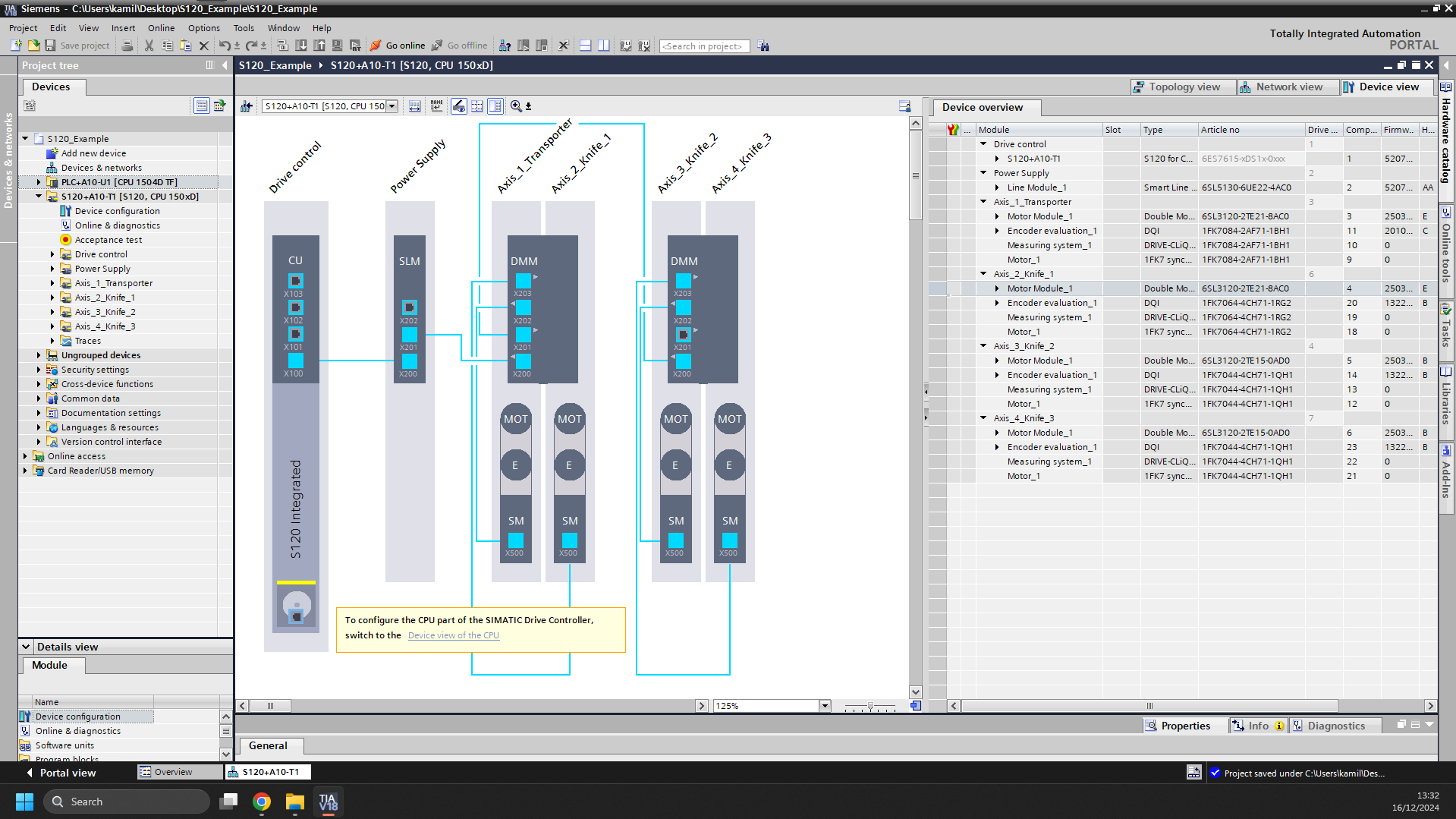

Follow these steps to configure SINAMICS S120 Double MOMO 5A/5A in TIA Portal:

- Add the PLC Controller: Select a compatible controller, such as SIMATIC S7-1500.

- Configure SINAMICS S120 in HW Config:

- Add the control unit (e.g., CU320-2) and power modules.

- Virtually connect the components according to the physical setup.

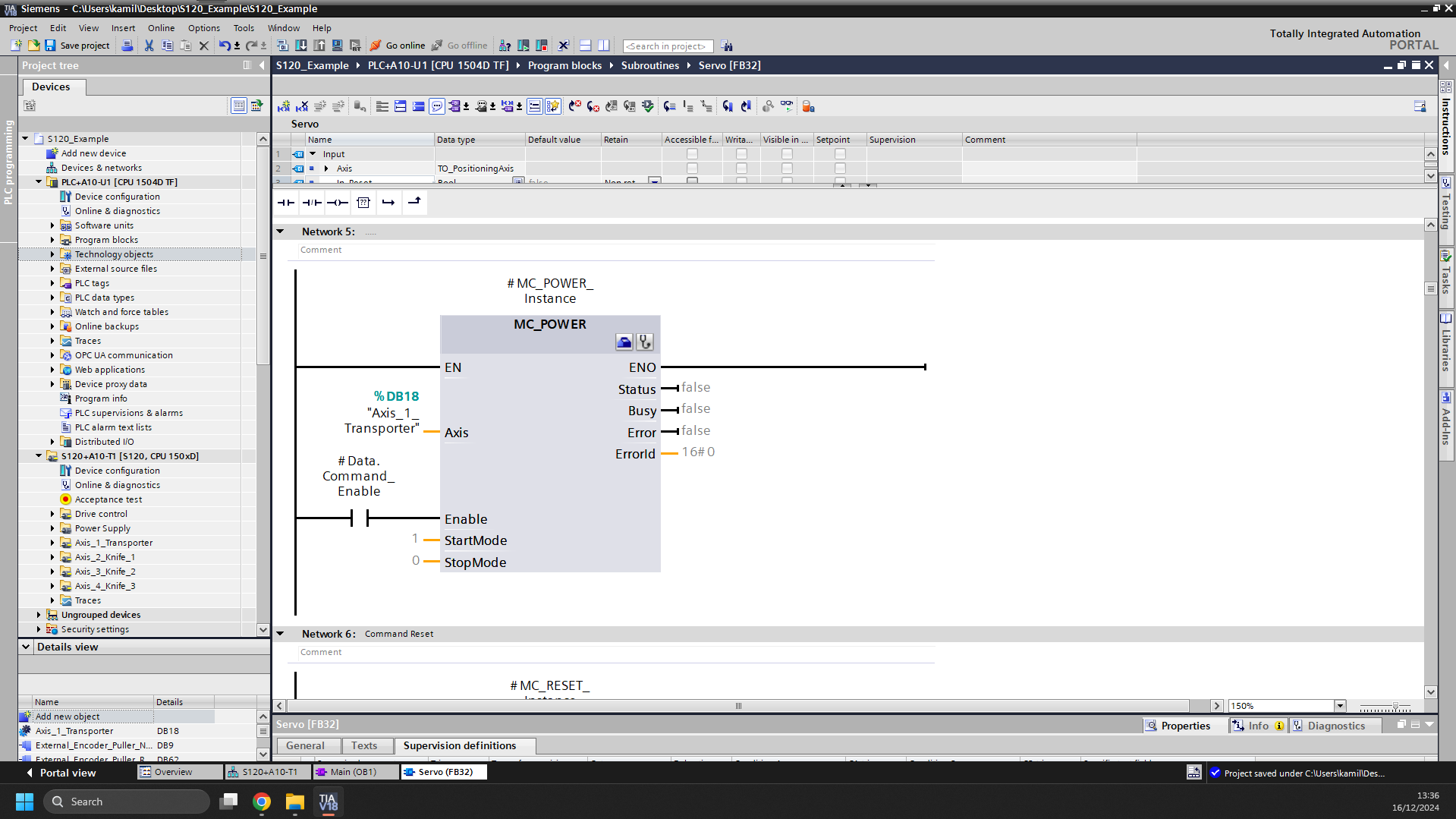

- Create a Technological Object: Set up an “Axis” object in TIA Portal for axis management.

- Program Motion Sequences: Use pre-configured PLCopen blocks for motion control.

- Testing and Commissioning: Simulate and test the configuration in TIA Portal.

Example Application

An example of a SINAMICS S120 Double MOMO 5A/5A application, including configuration in TIA Portal, can be found here:

1. Example SINAMICS S120 Application.

2. Example SINAMICS S120 Application.