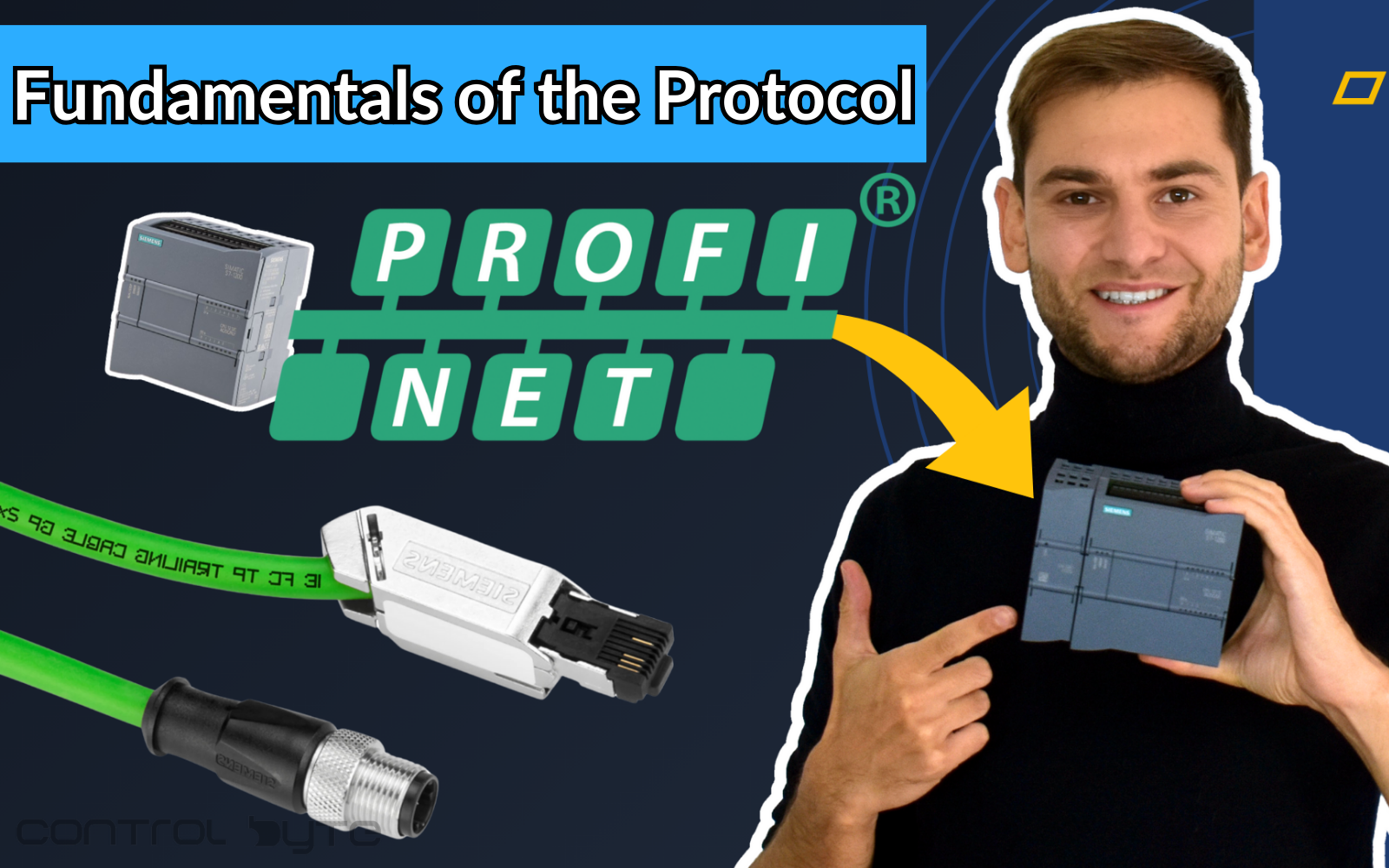

A Comprehensive Guide to PROFINET IO: Everything You Need to Know About Theory, Topologies, and Practical Applications

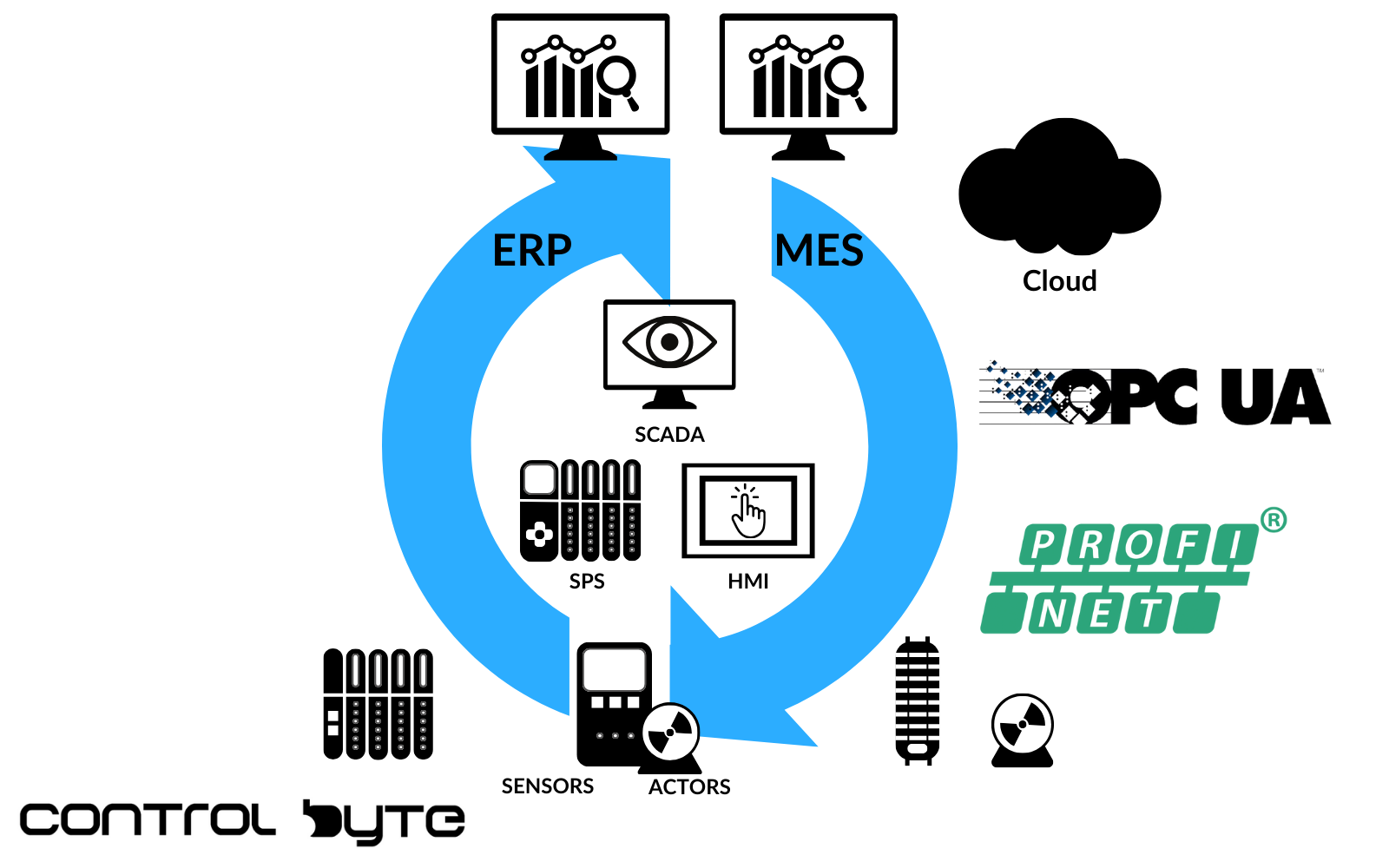

PROFINET IO is an automation standard based on Industrial Ethernet that has become the cornerstone of modern industrial automation. It bridges the IT world with industrial demands, offering unmatched performance and reliability in production environments. Below, you’ll find a comprehensive guide explaining what PROFINET is, its benefits, and how to implement it in practice.

PROFINET IO – What Is It, and Why Is It Revolutionary in Industrial Automation?

PROFINET IO was developed as a logical evolution of PROFIBUS DP technology, bringing Ethernet to industrial environments. Its main objectives include:

IT Integration: Enabling collaboration with management and data analytics systems.

Real-Time Operation: Supporting deterministic industrial applications.

Interference Resistance: Adapting to harsh working conditions such as electromagnetic interference and humidity.

With PROFINET, automation devices can interact with IT systems, enabling more efficient production management.

PROFINET Explained: How the Interface Revolutionizes Industrial Communication

In the fast-evolving world of industrial automation, PROFINET stands out as a game-changer in enabling seamless and efficient communication across devices. Designed to integrate industrial equipment with IT systems, this Ethernet-based protocol simplifies complex processes while ensuring real-time data exchange.

The PROFINET interface allows for flexible system configurations, providing manufacturers with the ability to design scalable and robust networks. By leveraging its capabilities, industries can achieve enhanced synchronization, streamlined diagnostics, and improved reliability—even in the most demanding environments.

From reducing downtime to fostering interoperability between devices from different manufacturers, the PROFINET interface offers a powerful solution for the challenges of Industry 4.0. Whether you’re upgrading an existing system or building a new network from scratch, understanding PROFINET’s fundamentals is key to unlocking its full potential in industrial communication.

Why Is Standard Ethernet Insufficient for Industrial Environments?

Office Ethernet, despite its popularity, does not meet the demands of production environments. Key limitations include:

Lack of Determinism: Office Ethernet cannot guarantee stable response times, which are critical in motion control.

Insufficient Durability: High temperatures, humidity, and electromagnetic interference are challenges office Ethernet cannot withstand.

Complex Integration: Connecting IT systems to automation previously required complicated gateways and converters.

The solution to these problems is Industrial Ethernet, with PROFINET as a flagship example.

Key Features of PROFINET IO That Make It a Leader in Industrial Automation

Real-Time Communication

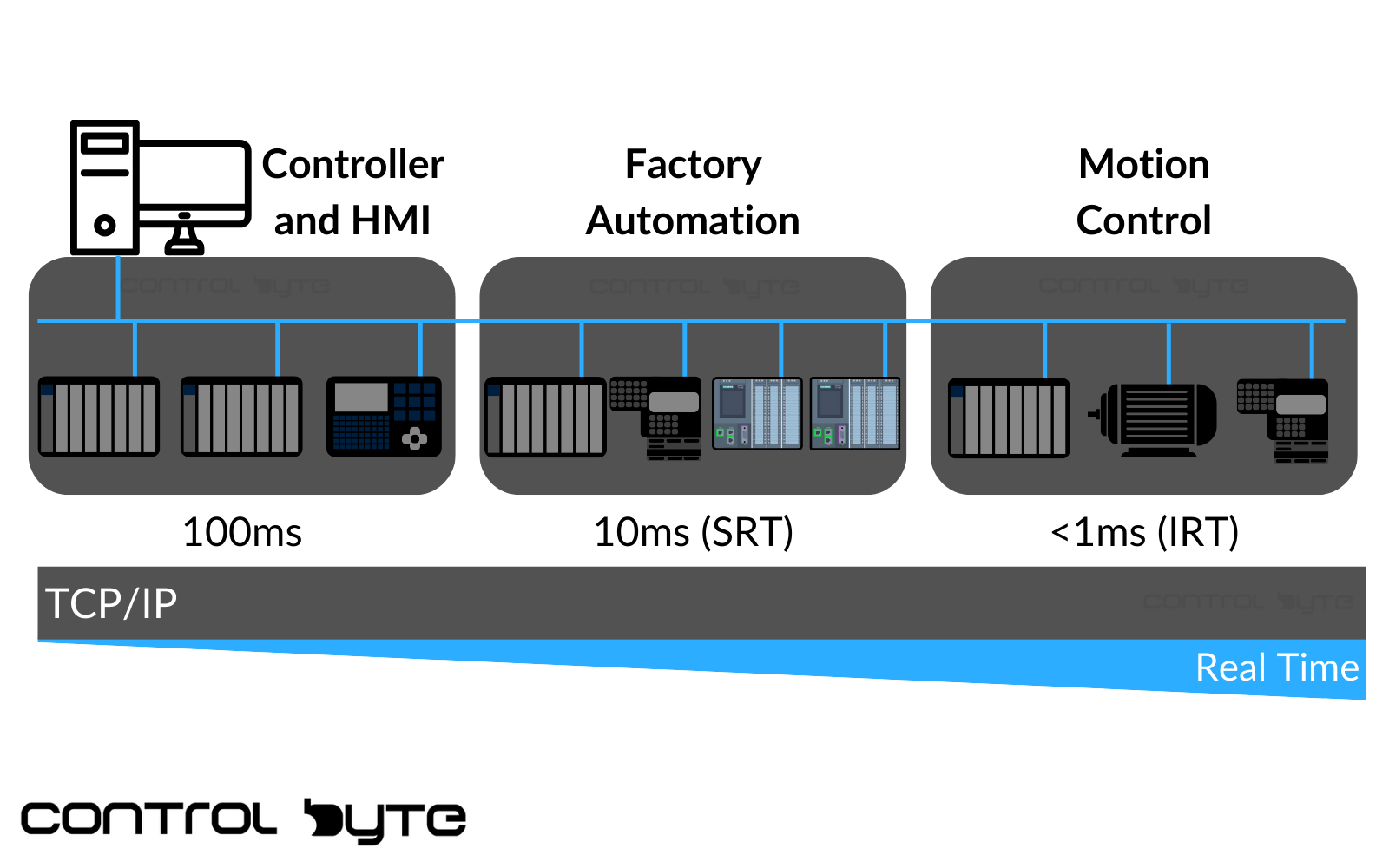

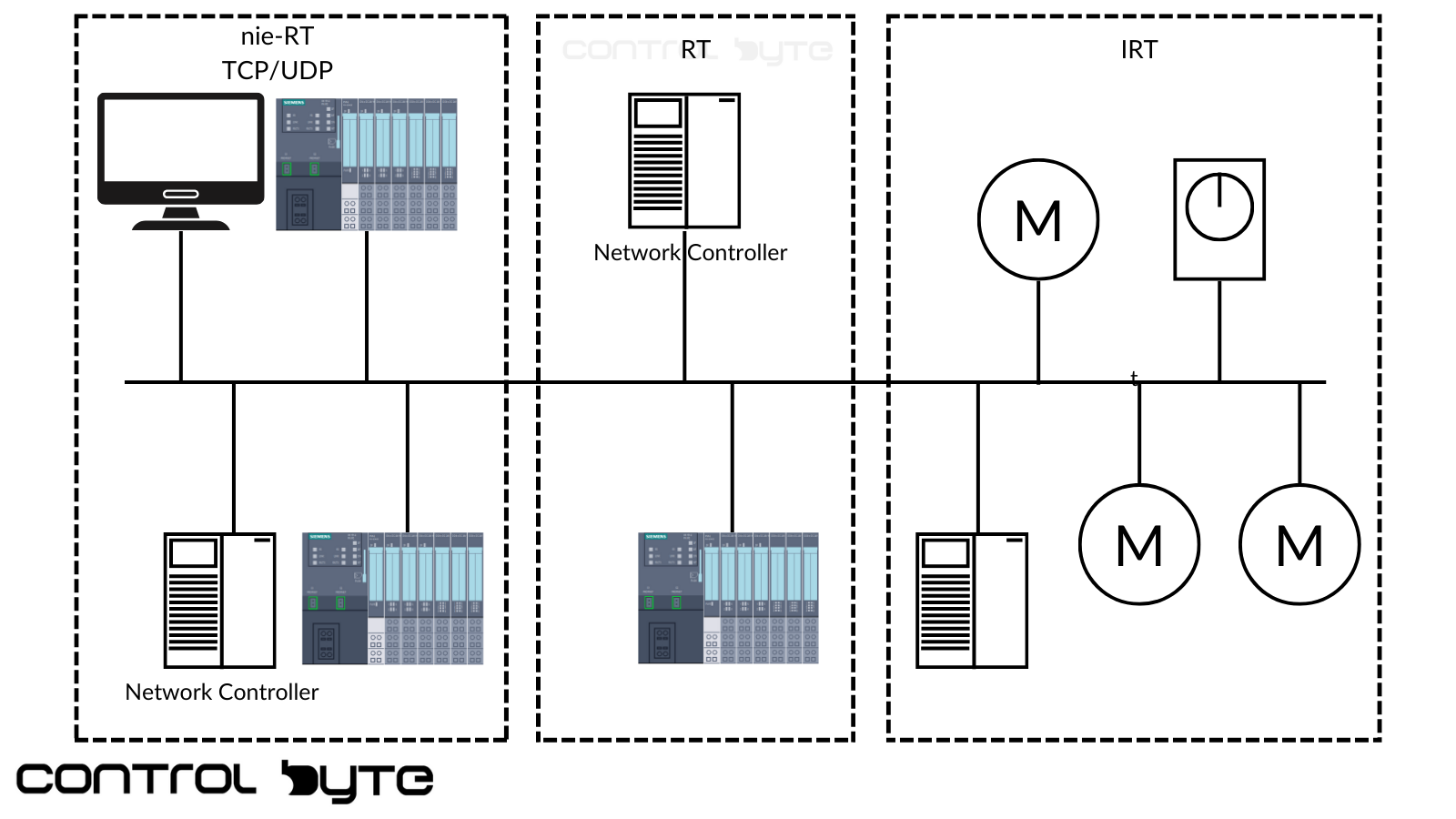

PROFINET IO supports three communication modes:

- TCP/IP: For non-deterministic functions such as reporting and management.

- Real-Time (RT): Deterministic data transfer with a refresh rate of 1–10 ms.

- Isochronous Real-Time (IRT): Microsecond-level synchronization, ideal for motion control and robotics.

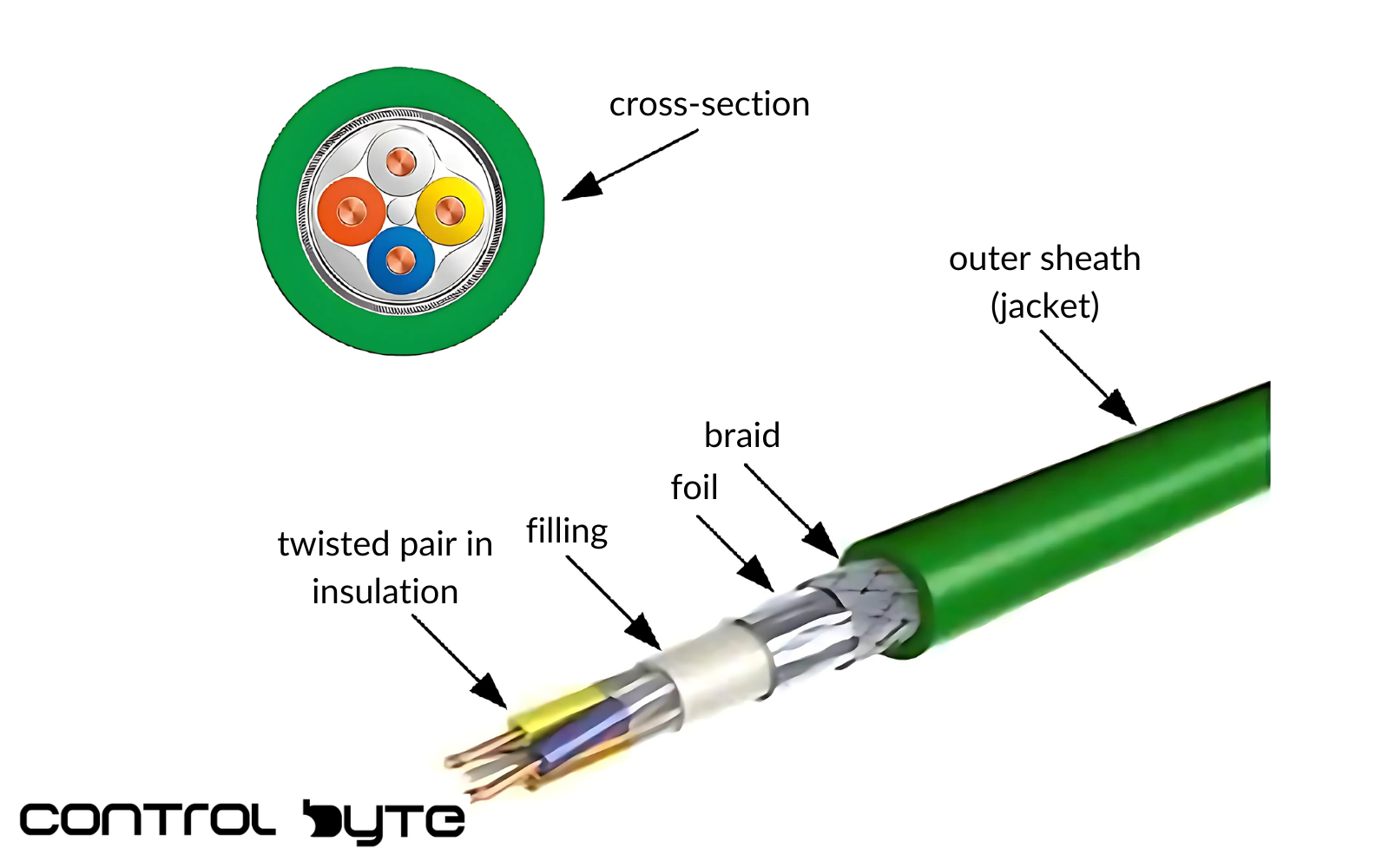

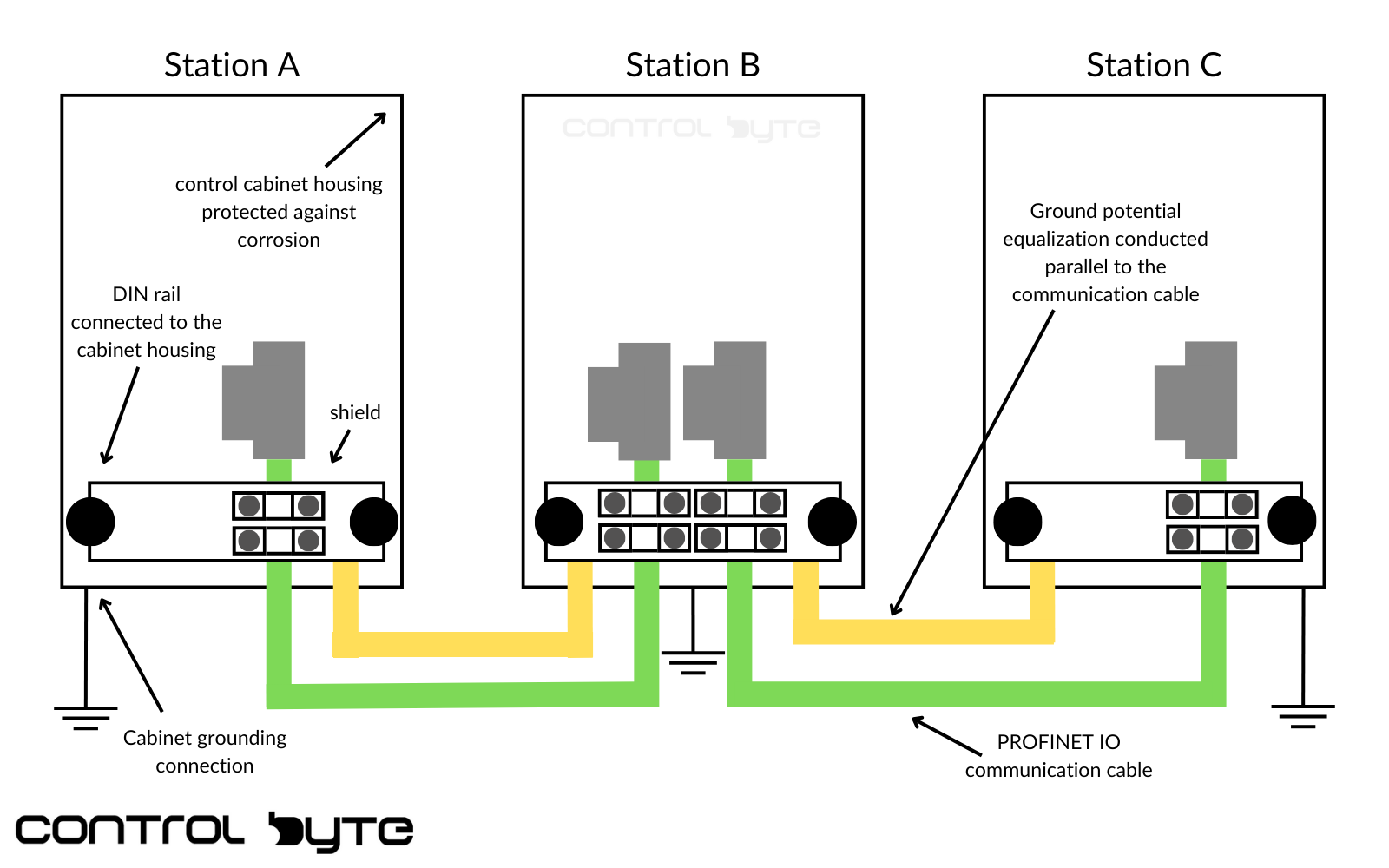

Interference Resistance

Shielding and grounding of PROFINET cables eliminate electromagnetic interference, ensuring stability and reliability in harsh conditions.

Compatibility with Ethernet

PROFINET operates alongside office Ethernet on the same infrastructure, allowing seamless IT and OT integration.

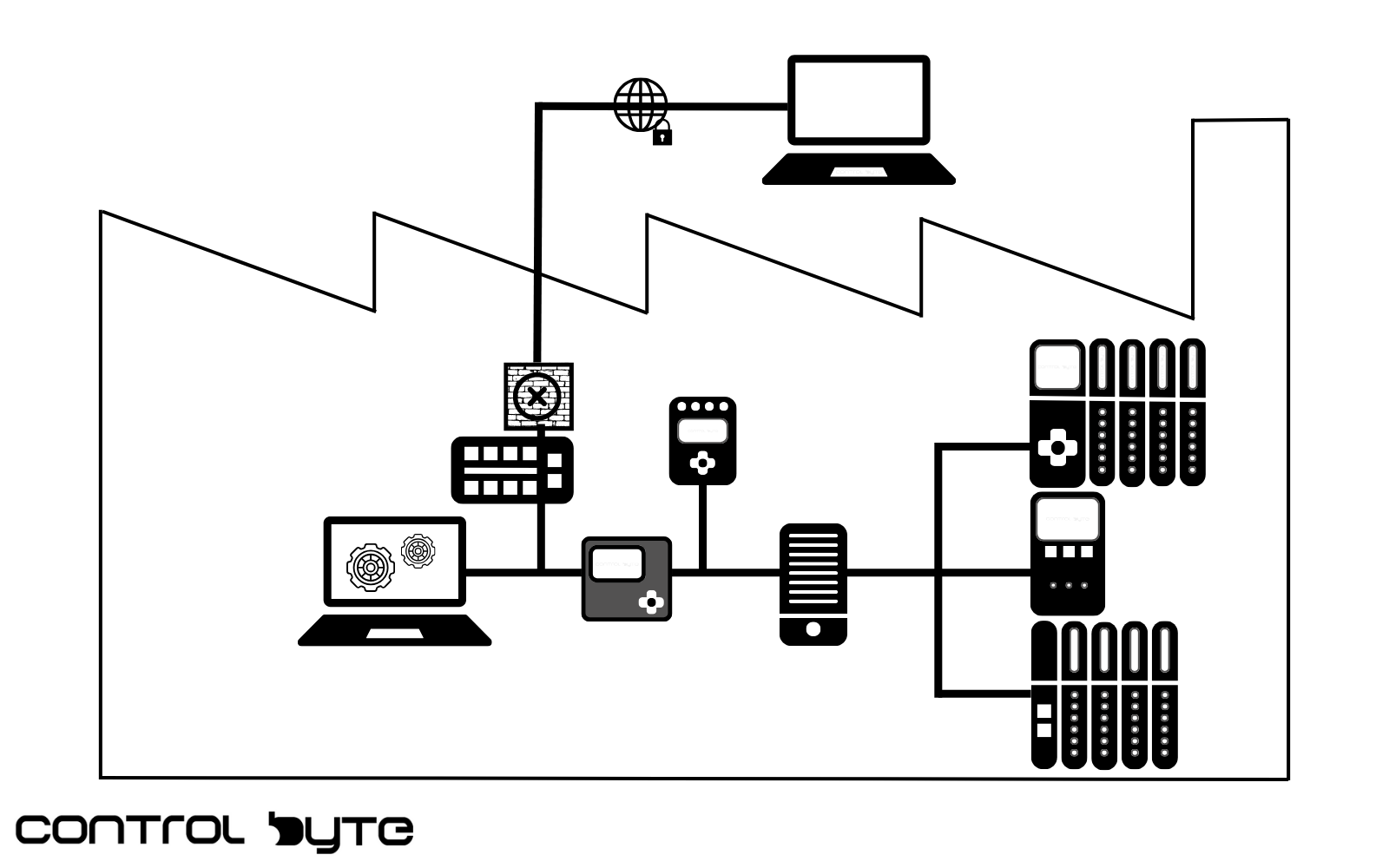

PROFINET Network Topologies: How to Design a Network for Your Plant

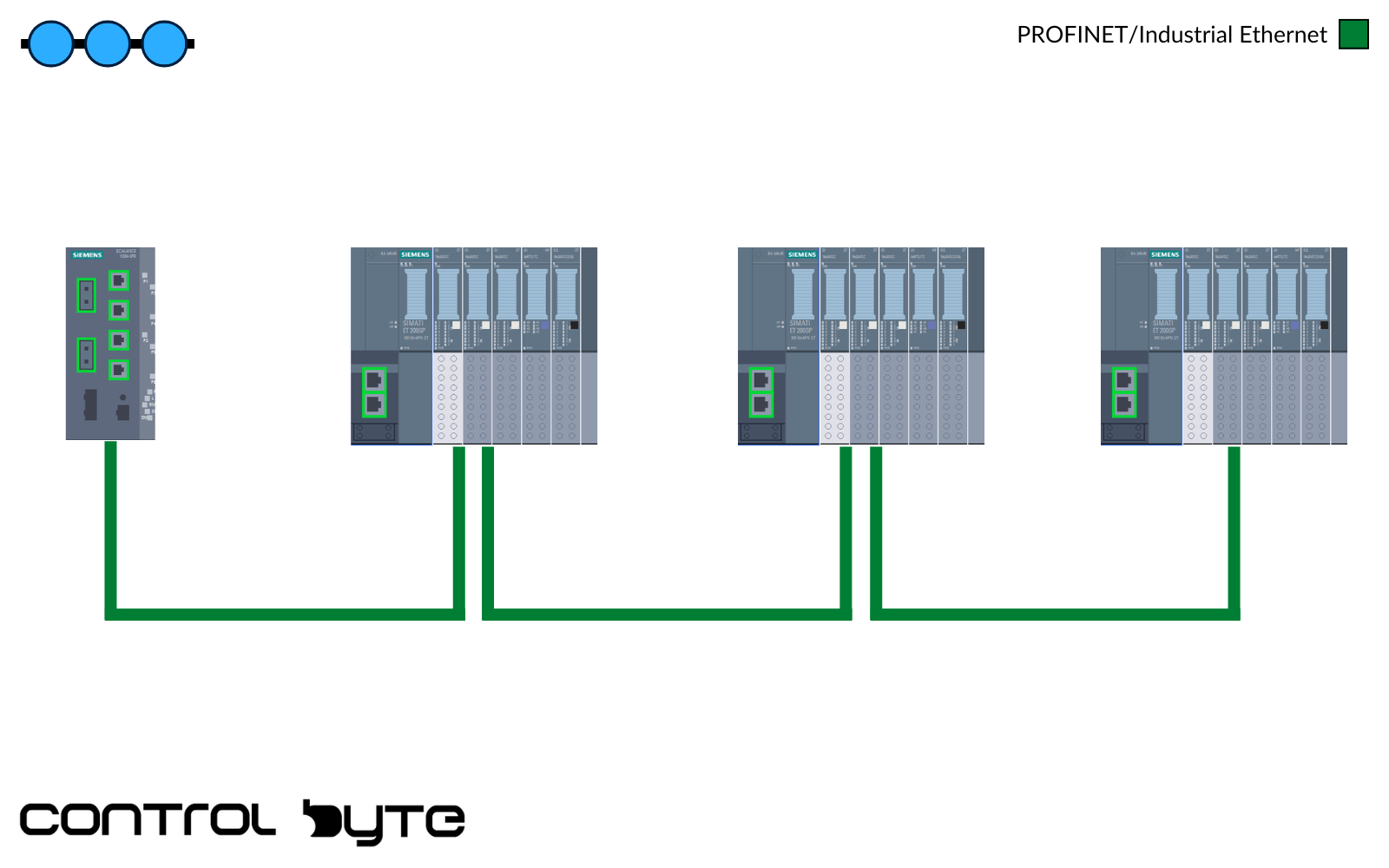

Linear Topology

The simplest solution requiring minimal cabling but susceptible to outages if one device fails.

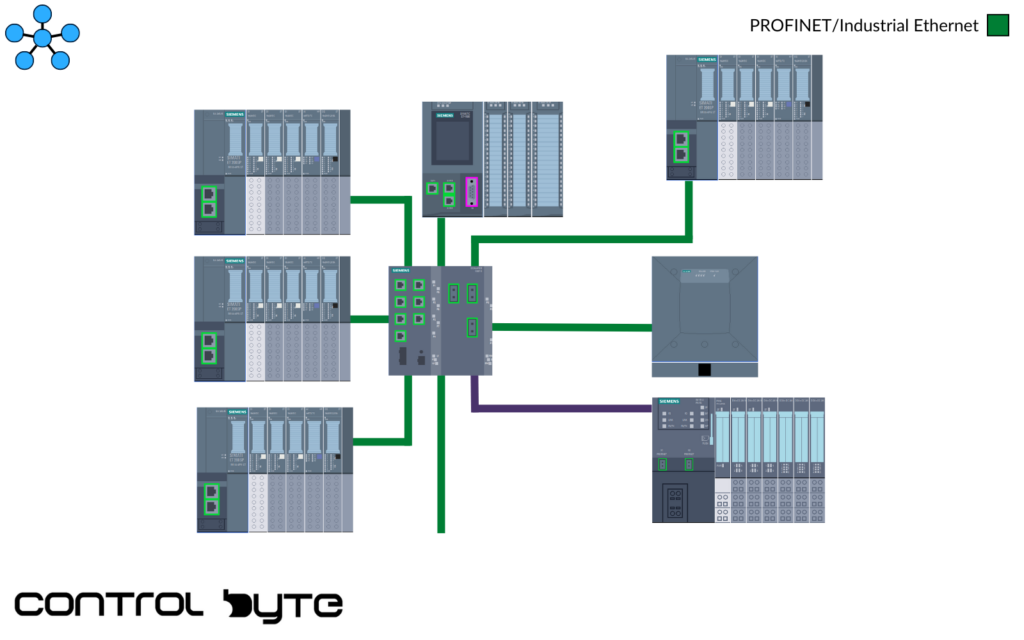

Star

Devices connect to a central switch, offering greater reliability than linear setups.

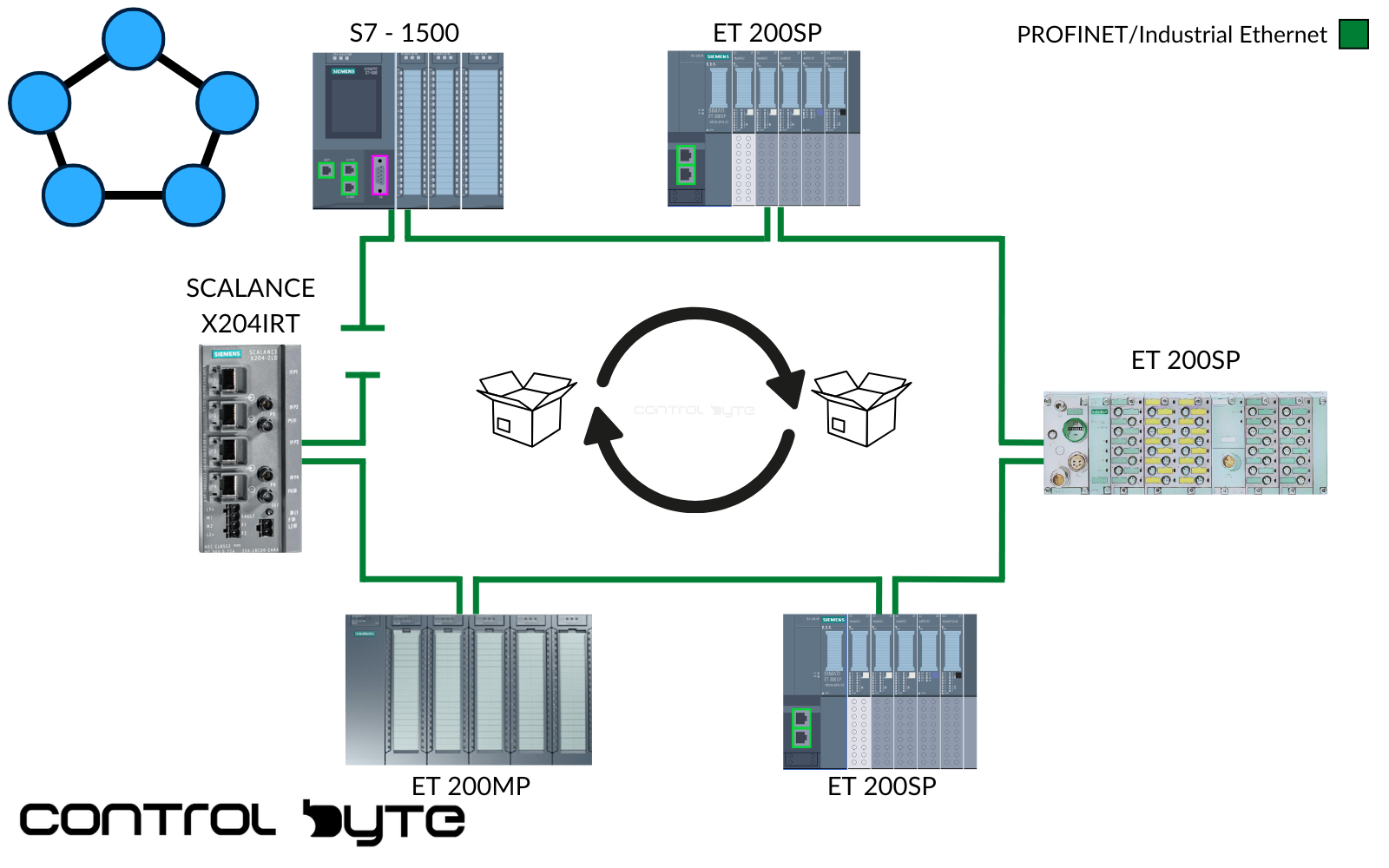

Ring

Provides the highest reliability through redundancy mechanisms. In case of a single connection failure, data is rerouted.

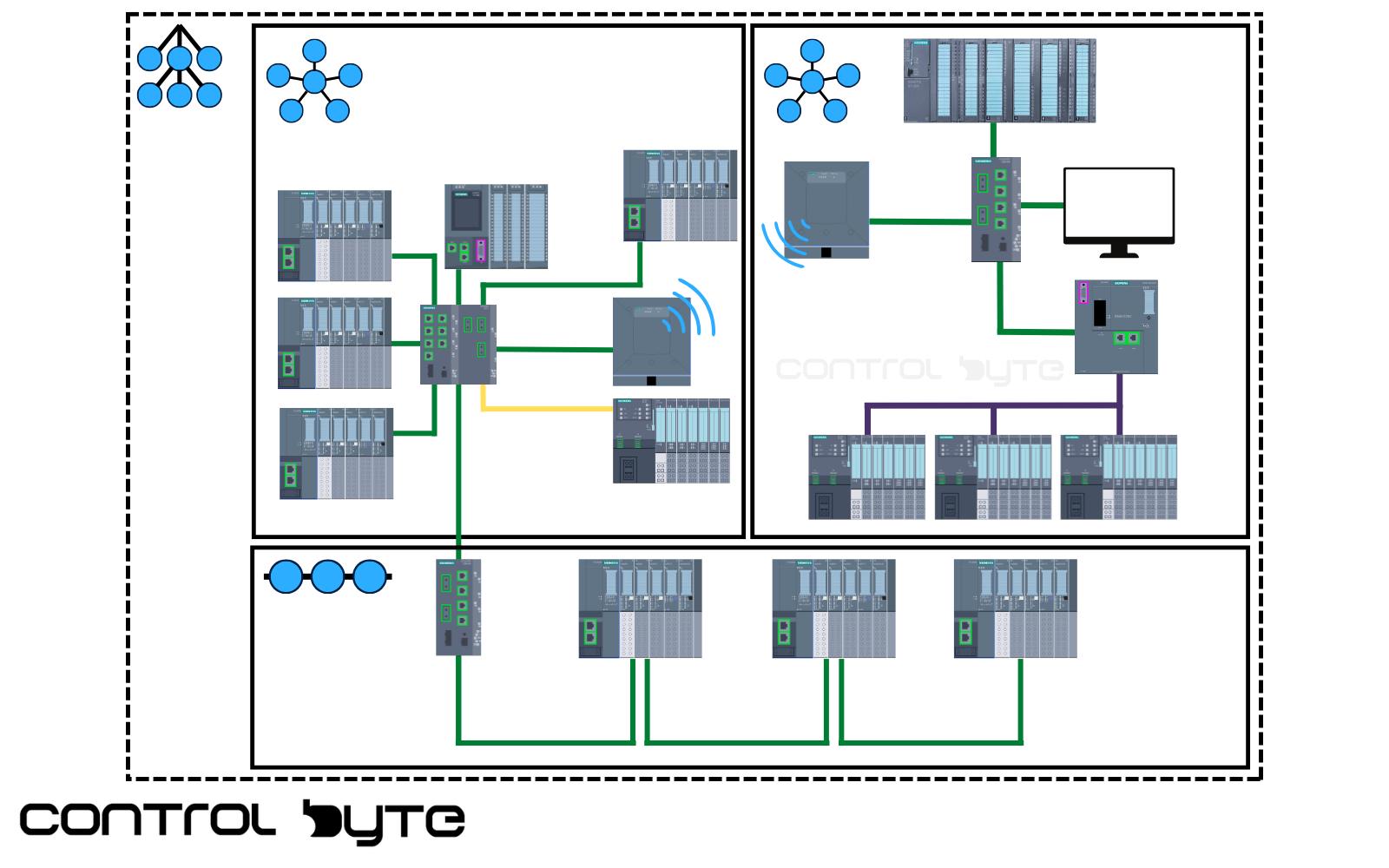

Tree

Combines multiple stars into a hierarchical structure, ideal for large networks.

Installation Tips: How to Build a Reliable PROFINET IO Infrastructure

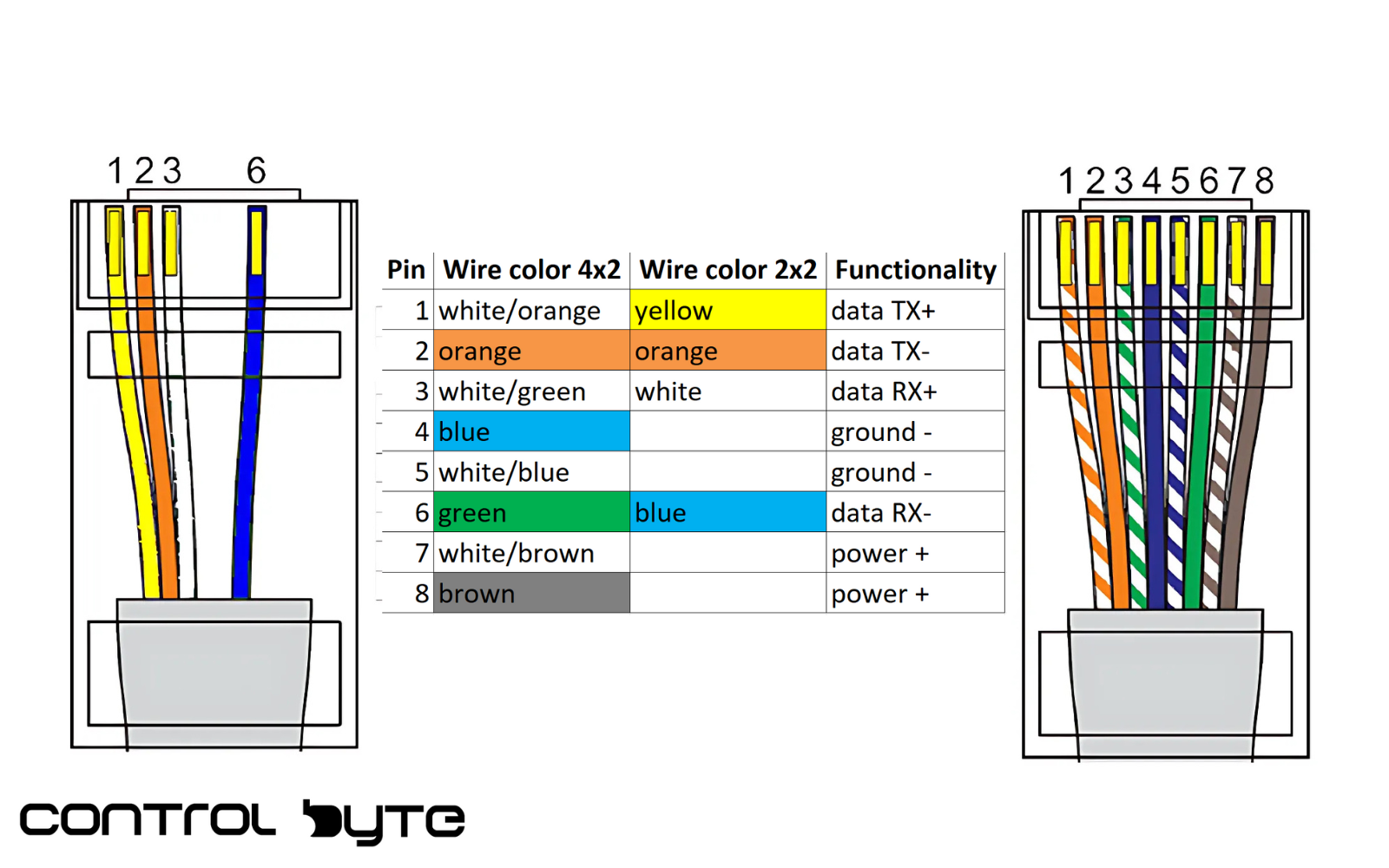

Cable Selection

- Copper Cables (CAT5): For standard applications.

- Fiber Optics: For environments with high electromagnetic interference.

Installation Guidelines

- Limit connections to six to avoid signal attenuation.

- Ground cables at both ends.

- Use shielded connectors in harsh conditions.

Compliance Classes

- Class A: For simple applications.

- Class B: For devices with management functions.

- Class C: For demanding applications with redundancy.

Diagnostic Tools and Network Management in PROFINET

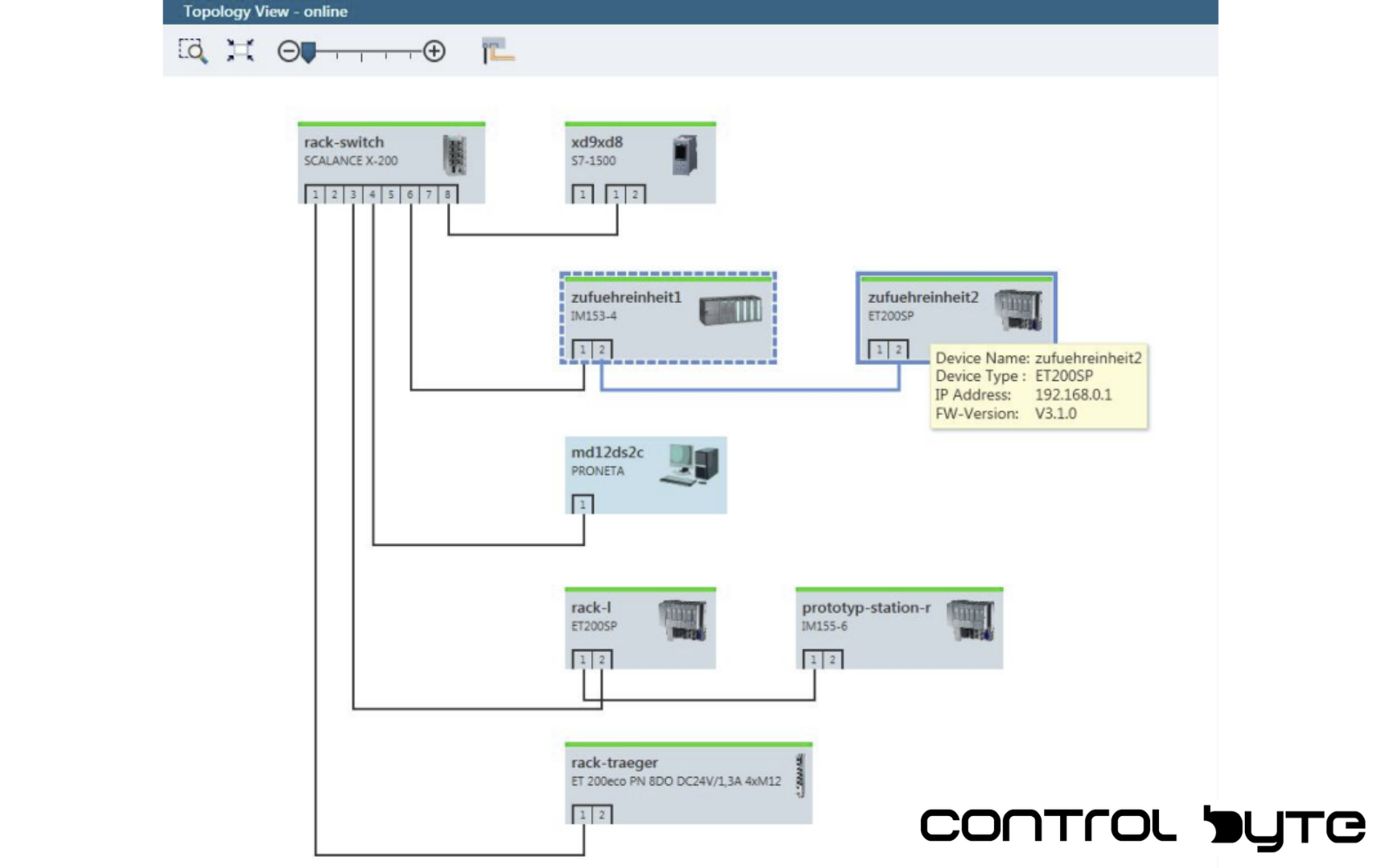

PRONETA

A tool for automatic device detection, I/O testing, and performance monitoring.

LLDP Protocol

Allows automatic network topology mapping, simplifying diagnostics and management.

TIA Portal – Diagnostic Features

TIA Portal offers advanced diagnostic features for easy network monitoring and management. Users can dynamically map network topology, diagnose devices in real time, and quickly locate and resolve issues. The tool supports LLDP for automatic device detection and network structure analysis. Process data monitoring further simplifies the identification of I/O errors. An intuitive interface and integration with tools like PRONETA make diagnostics fast, accurate, and cost-effective. TIA Portal is an indispensable support for managing modern automation systems.

PROFINET IO Applications: Industries and Use Cases

PROFINET is used in:

- Production Automation: Precise synchronization of machines and devices.

- Motion Control: Enabled by IRT mode.

- IT and OT Integration: Facilitating smooth data exchange between production processes and management systems.

The Perfect Foundation for Industrial Automation

PROFINET IO harmoniously combines Ethernet’s flexibility with the reliability and resilience required in industrial environments. With real-time operation, durability in harsh conditions, and IT integration capabilities, It is a key component of modern automation systems. Its use not only boosts efficiency and reduces downtime but also paves the way for process digitalization, offering better control, precision, and readiness for Industry 4.0 challenges. Choosing PROFINET IO is an investment in the future and technological advancement of your facility.

Practical Examples of PROFINET IO Configuration – How to Implement It in Your Plant

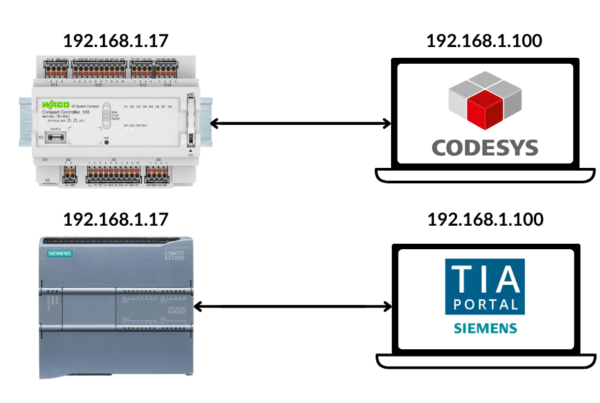

Configuring PROFINET Devices

A key step in implementation is correctly configuring IO devices. Assigning IP addresses, device names, and identification numbers enables easy network recognition. Examples include:

- PLC Controllers: Configuring communication between PLCs and field devices using PROFINET IO.

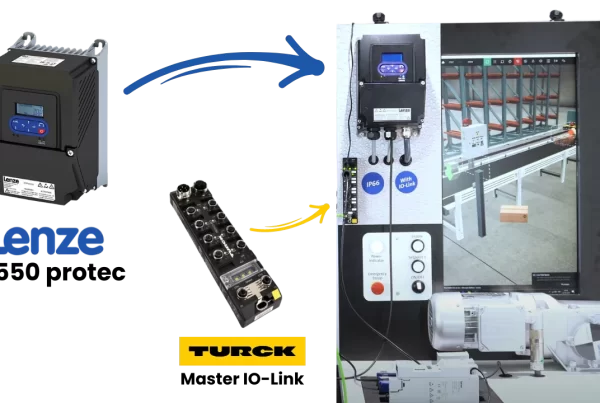

- Drives: Integrating drives like Lenze i550 with control systems through parameter channels.

Implementing Redundancy and Topology Management

To ensure network reliability, a ring structure with redundancy mechanisms is recommended. This setup reroutes data automatically in case of device or cable failure.

Configuration Tools

- PRONETA: Simplifies I/O testing and device diagnostics.

- STEP 7: PLC programming software for seamless integration with PROFINET devices.

Benefits of Implementing PROFINET IO in Modern Industrial Facilities

Increased Efficiency and Productivity

Real-time data transfer eliminates downtime and enhances machine productivity. Process synchronization enables more precise control.

Cost Reduction

- Reduced Cabling: Leverages existing Ethernet infrastructure.

- Ease of Configuration and Diagnostics: Tools like PRONETA minimize system setup time and costs.

Future-Readiness

PROFINET supports technologies like Industry 4.0 and the Internet of Things (IoT), making it essential for digital transformation in production facilities.

Conclusion: Why PROFINET IO Is the Future of Industrial Automation

PROFINET IO is not just advanced communication technology but the foundation of modern manufacturing. Its real-time capabilities, resilience in industrial environments, and integration with IT systems make it the ideal solution for any company striving for enhanced efficiency, flexibility, and reliability.