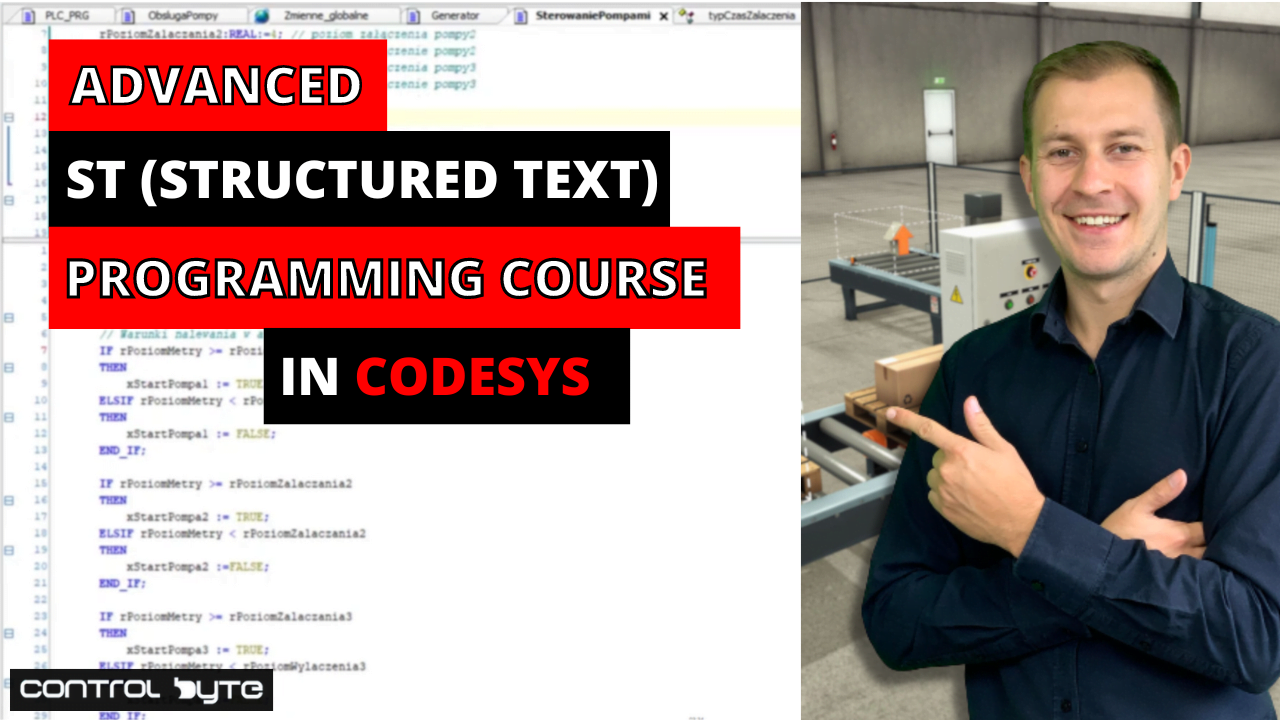

Advanced PLC Structured Text course in CODESYS

You will program a PLC controller in the text-based ST language in the CODESYS environment!

What makes the PLC ControlByte courses so popular?

-

You get access to video lessons on the e-learning platform

-

You perform programming exercises based on the provided project templates. All you need is your PC and a simulator!

-

You can take the course whenever and wherever you want.

-

You can start the course at a later date.

-

You will have homework to do on your own!

-

You get course support through Discord chat and live meetings.

“I believe that everyone in the 21st century should know the basics of programming and automation!”

Maciej Kurantowicz

Master of Engineering in automation and robotics, graduate of Wroclaw University of Technology. He also studied in England and Germany.

-

He gained experience in small start-ups, and then in international companies like: Bosch, Mitsubishi Electric or WAGO.

-

He specializes in programming PLC controllers in the Codesys environment in the Structured Text language.

-

He has already trained over 400 automation technicians in the field of PLC controller programming

What will you get after enrolling in this course?

-

Over 120 practical video lessons

-

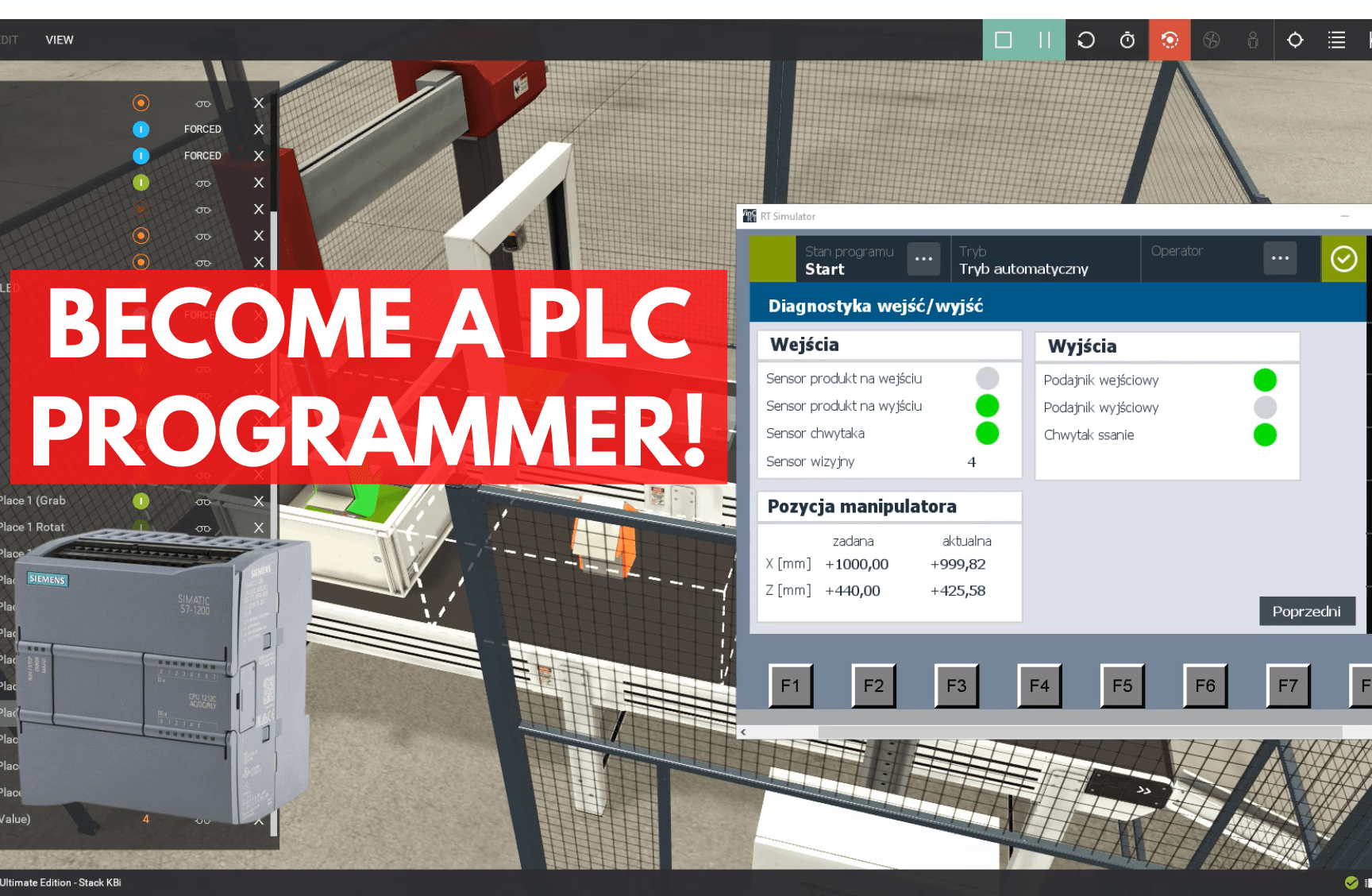

You will test your programs in the virtual Factory IO factory

-

Support from instructors in the form of Discord chat and live meetings

-

You will have homework to do on your own!

-

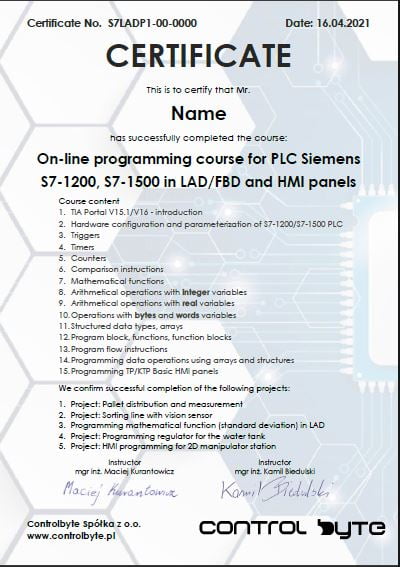

A certificate of completion of the course in Polish and English.

Program flow control

Module contents:

-

Conditional statement IF…ELSIF…ELSE

-

FOR…DO loop

-

WHILE…DO and REPEAT…UNTIL loop

-

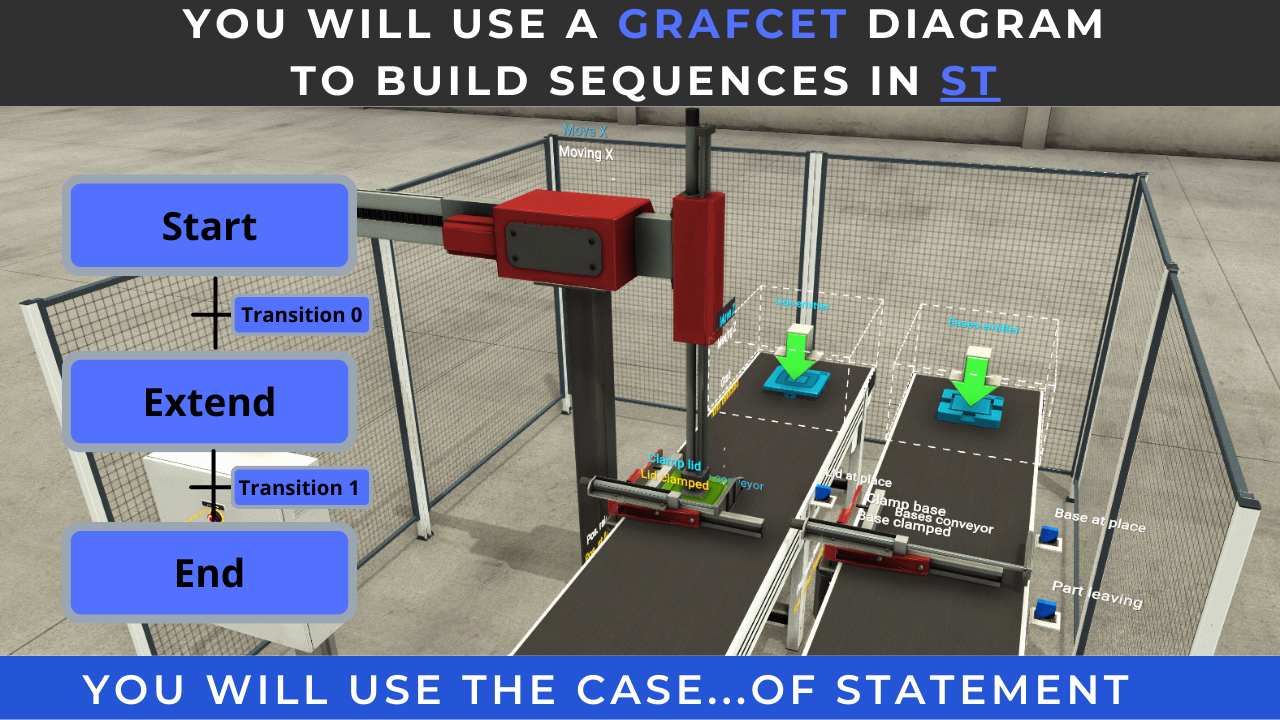

Conditional statement CASE…OF

-

Exercises on projects and contact with the instructor

Projects in the PLC simulator.

-

Temperature controller in a control cabinet (IF…ELSE)

-

Parcel weighing (CASE…OF)

-

Pneumatic hose cutting station

-

PI controller for a liquid tank

-

Pallet buffering line

-

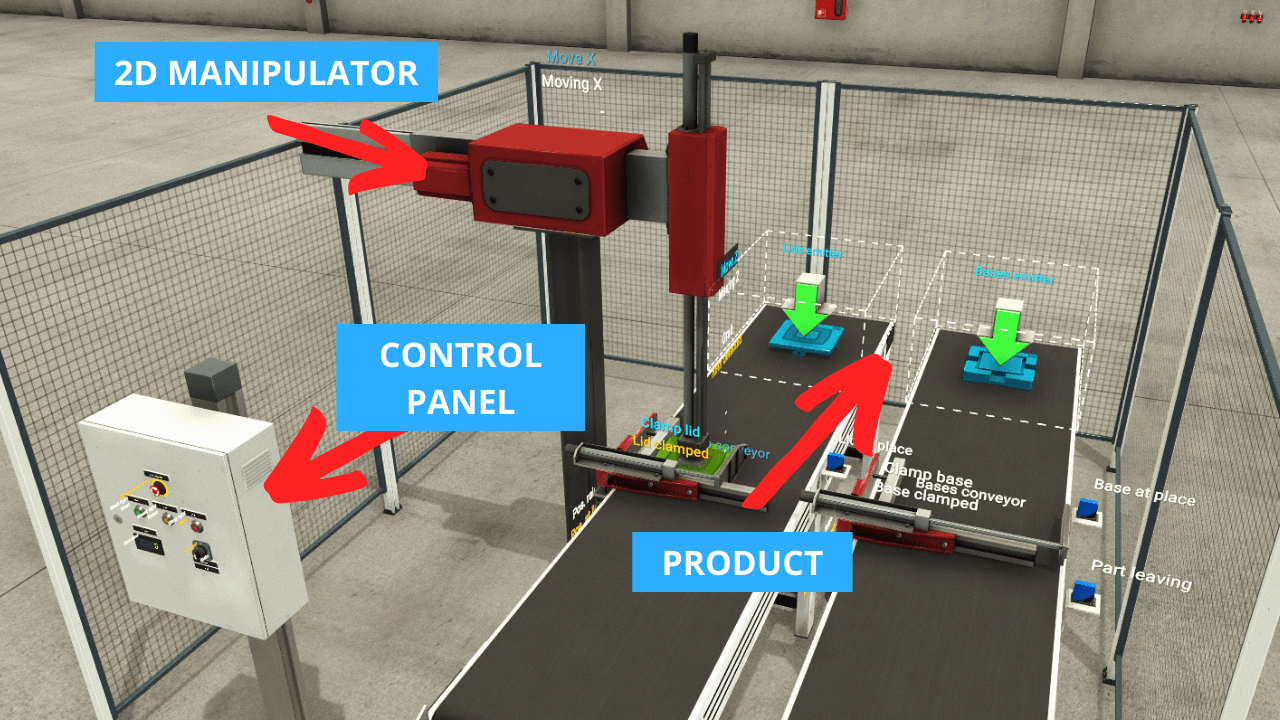

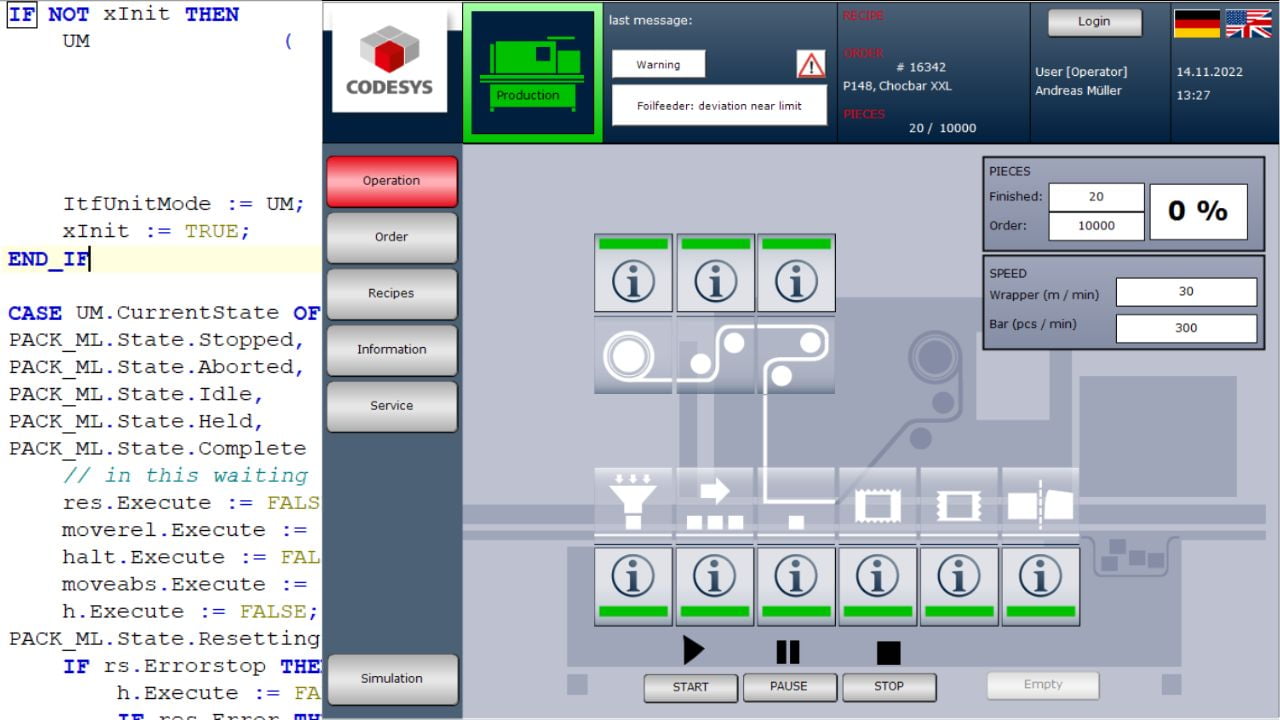

2D manipulator and visualization in Codesys

-

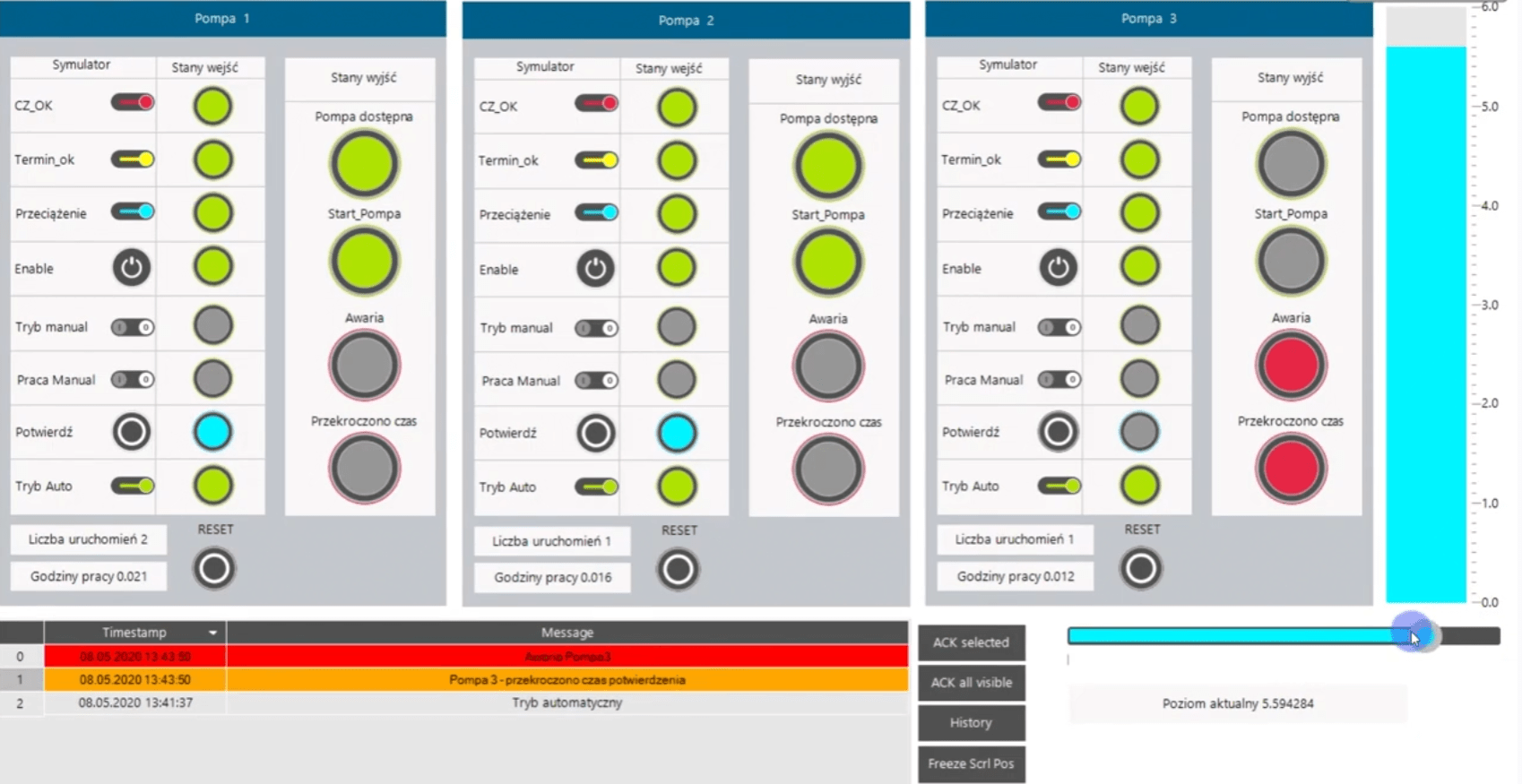

Pumping station

Handling PLC equipment in the course

-

WAGO 750-8202 PLC controller

-

Turck TX707 HMI panel

-

Weintek CMT2078X panel

-

Raspberry PI as a PLC

-

Communication with external Modbus devices

Visualization in Codesys

-

Basic elements: lights/buttons/actuators

-

Handling of alarms and animations

-

Visualization templates for download

-

How to display web visualization in the browser

-

Uploading visualization to the HMI panel

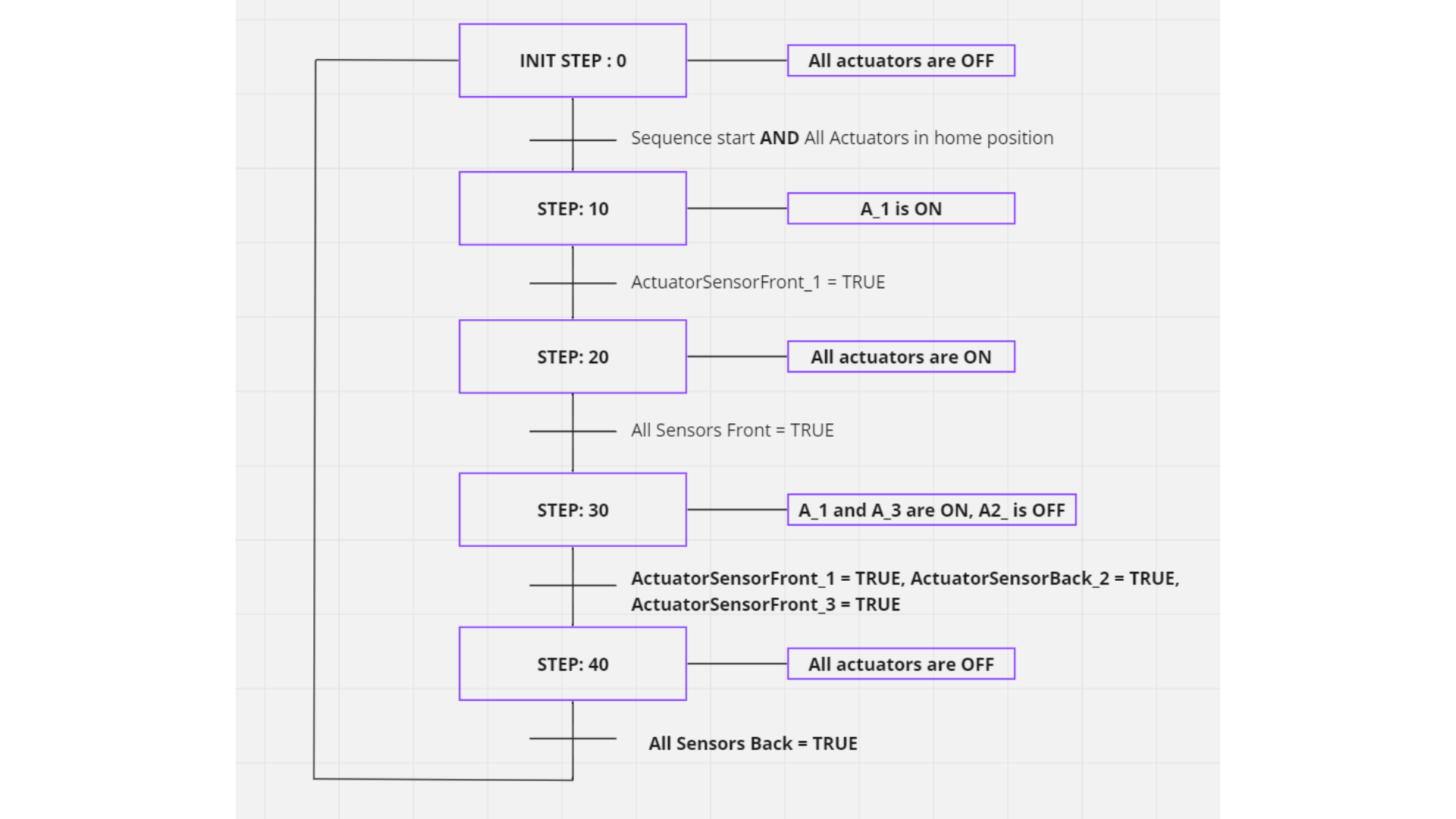

Programming sequences for machines

-

Analysis of the scene with a 2D manipulator in Factory IO

-

Designing sequences on a Grafcet diagram

-

Programming function blocks for feeders

-

Handling machine sequence steps

-

Designing visualizations and testing

Course content

1. Introduction to the course

1.1 How to use the course

1.2 Knowledge Forum – Discord Group

1.3 How to remake a module: Introduction to the course

1.4 Introduction to ST language

1.5 Codesys environment installation (8 min)

1.6 First ST program

1.7 ST language – knowledge test

1.8 Simple visualization in Codesys

2. Variables

2.1 Memory units, variable and constant definition

2.2 How to name variables, type BOOL

2.3 BOOL variable declaration

2.4 Integer variables – introduction

2.5 Integer variables – exceeding the range

2.6 Real variables

2.7 Tables

2.8 Structured type

2.9 Enumeration type

2.10 Local and global variables

2.11 Variables – Knowledge Test

2.12 Variables Homework

3. Operators

3.1 How to use the module: Operators

3.2 Assignment operator

3.3 Arithmetic operators

3.4 Logical Operators

3.5 Comparison operators

3.6 Operator Priorities

3.7 Operators – Knowledge Test

3.8 Project: Cutting station – declaration of variables

3.9 Project: Cutting station – visualization

3.10 Project: Cutting station – program testing

3.11 Project: Cutting Station – Homework

4. Program flow control instructions

4.1 IF statement

4.2 IF, ELSIF, ELSE statement

4.3 CASE…OF statement

4.4 WHILE loop

4.5 FOR loop

4.6 Program flow control instructions – knowledge test

4.7 Introduction to the design of the controller in the control cabinet

4.8 Project: Three-position temperature controller in the control cabinet

4.9 Visualization: Three-position temperature controller in the control cabinet

4.10 Graph for temperature controller

4.11 Project – Loading packages into container p1

4.12 Project – Loading packages into p2 container

4.13 Installing Factory IO

4.14 Program and configuration of Codesys communication with Factory IO

4.15 Conveyor simulation in Factory IO (15 min)

4.16 Project – Proportional Regulator for Liquid Tank – Introduction

4.18 Project – Proportional Regulator for Liquid Tank – Homework

4.17 Project – Proportional controller for liquid tank – implementation

5. Software Organizational Units (POUs)

5.1 What is a program?

5.2 Function vs Function Block

5.3 Examples for FUN and FB

5.4 Action

5.5 Software Organizational Units (POU) – knowledge test

5.6 POU – homework

6. Operations on strings

6.1 String operations – theoretical introduction

6.2 Testing functions from the STANDARD library

6.3 Installing the OSCAT BASIC library

6.4 String operations – knowledge test

6.5 Project: Label for Zebra printer – introduction

6.6 Project: Label for Zebra printer – declaration of necessary functions and data structures

6.7 Project: Label for Zebra printer – Project: Label for Zebra printer – preparation of the date in the correct format

6.8 Project: Label for Zebra printer – preparing the time in the appropriate format

6.9 Project: Label layout programming

6.10 Project: Zebra Printer Label – Homework

Sending a label to a Zebra printer over TCP

7. Floating point operations and analog scaling

7.1 Functions: ROUND, CEIL, FLOOR, TRUNC

7.2 Operations with floating point numbers – knowledge test

7.3 Scaling an analog quantity – program

7.4 Scaling an analog quantity – visualization

8. Edge detection - triggers

8.1 R_TRIG, F_TRIG instructions

8.2 Edge detection – knowledge test

9. Timing instructions - Timers

9.1 TP Timer

9.2 TON Timer

9.3 TOF Timer

9.4 SR, RS flip-flops

9.5 Time instructions – Timers – knowledge test

9.6 Line protection – TON timer

9.7 Timing Instructions – Factory I/O Homework

10. Counters

10.1 CTU Counter

10.2 CTU – homework

10.3 CTD Counter

10.4 CTUD Counter

10.5 Counters – knowledge test

10.6 Project: Queuing Packets in Factory I/O – Homework

11. Indicators

11.1 Pointers in Codesys

11.2 Pointers: Array operations

11.3 Pointers: String operations

11.4 Modbus Master – float variable reading

11.5 Arrays of various sizes

11.6 Indicators – knowledge test

11.7 Indicators Homework

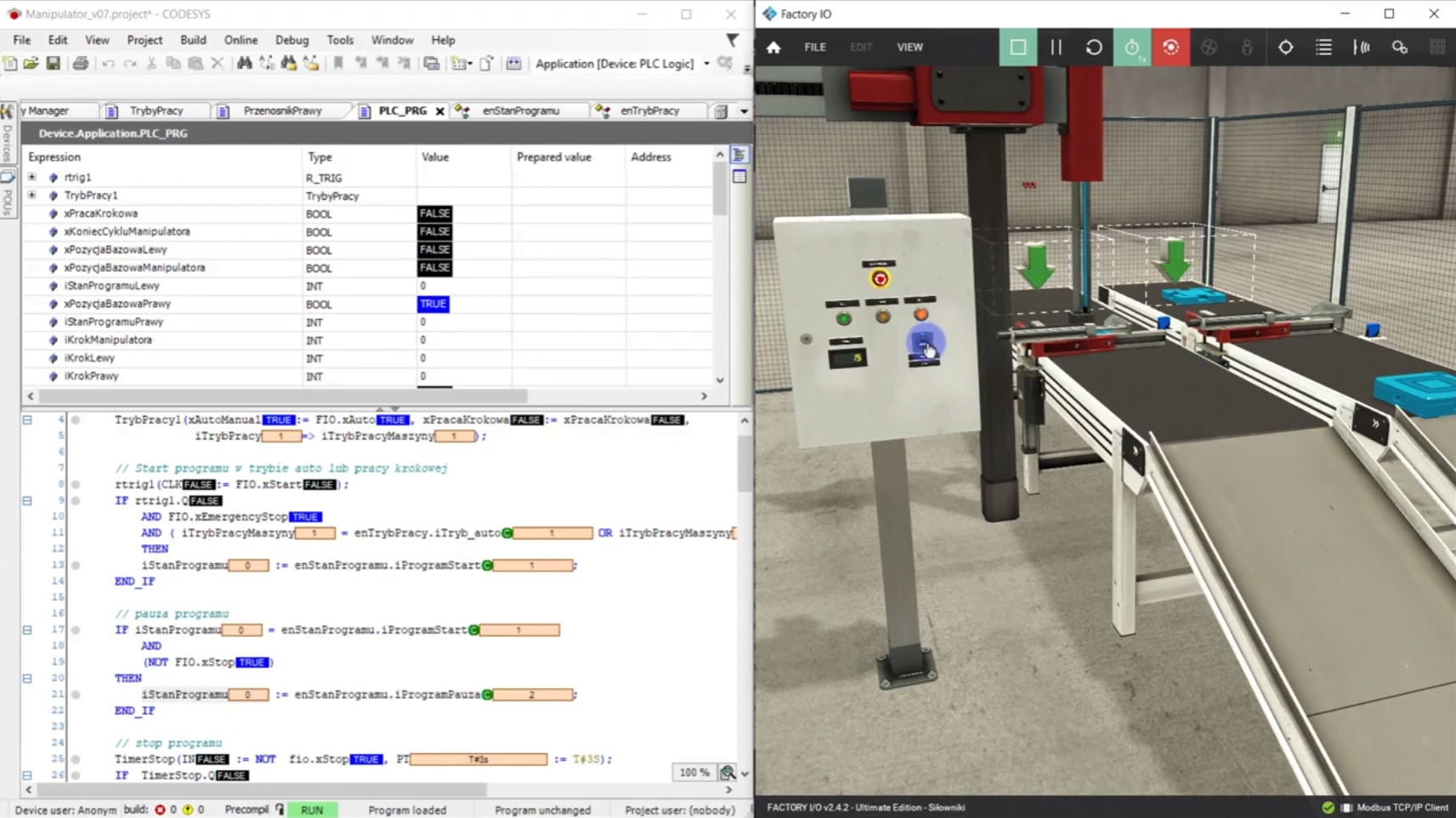

12. Project: 2D manipulator - programming a sequential control system

12.1 Project description

12.2 Variable mapping

12.3 Object analysis – how to program parallel sequences?

12.4 Sequence of objects – grafcet

12.5 Simulation of limit sensors for an axis

12.6 Manipulator sequence program

12.7 Sequence feeder left program

12.8 Conveyor sequence right program

12.9 Keypad auto/manual/step modes

12.10 Operating modes for conveyors

12.11 Main Program and Function Blocks

12.12 Program tests

12.13 Alerts

12.14 Visualization

12.15 Visualization and program tests

2D manipulator – sequential control system programming – homework

13. Project: Factory I/O pumping station

13.1 Project description

13.2 Function blocks: generator, pump control

13.3 Function block: pump operation

13.4 Main program

13.5 Visualization pattern

13.6 Visualization project

13.7 Alarm programming

13.8 Program and visualization tests

3D simulation of the HOME IO smart home (Module available from April 23)

Project description

HOME IO and Connect IO installation

Codesys Connect IO communication, test program

Homework: garage gate control

Homework: garage control panel

Nav bar on visualization

User login on visualization

Weather forecast panel

PID temperature controller for living room

PID support for all rooms

Visualization for temperature controller

Downloading the current date and time

Energy consumption monitoring program

Energy consumption monitoring visualization

Device scheduler

Web visualization

Bonus Module 1

1. Configuration and programming of the PLC/HMI controller part 1TURCK TX707-P3CV01

2. Configuration and programming of the PLC/HMI TURCK TX707-P3CV01 part 2

3. Description of the WAGO modular automation system

4. Designing a WAGO node – Smart Designer

5. Establishing connection with the WAGO controller

6. Preparing the PFC200 controller to work in Codesys

Equipment in the course

To complete the course, the CODESYS environment simulator is sufficient.

As a bonus, we will show you how to configure the controller.

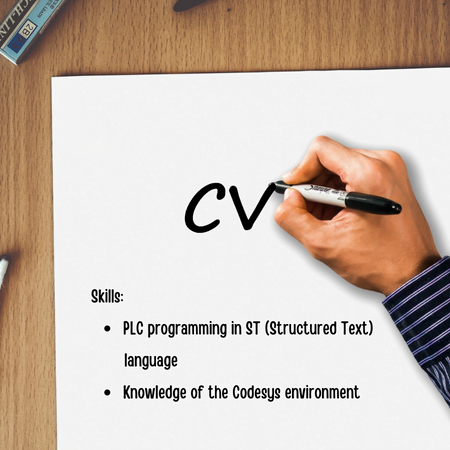

Why should you join this course?

-

You gain a skill highly valued by employers. You can showcase your certificate on LinkedIn, Goldenline, and, of course, in your CV!

-

If you want to change your job and take on a position as an automation engineer in a company, you are in the right place!

-

You receive lifetime access to the course materials on our platform. You can revisit them whenever you want.

-

You can test all your written code in the virtual factory in Factory IO.

-

In the course, you don’t need hardware. Simulators like PLC and Factory IO are sufficient. The code you write can be used in real projects.

-

Hundreds of students have verified this learning path. Ask them what they say about us in the industry!

Course price

Before I show you the price, see what exactly you get when you join the ST course:

Thanks to the proven formula of our training and cost optimization, you can purchase this training for:

199 $

Join now for 199$

Course currently unavailable...Kliknij w przycisk i odbierz zniżkę (nawet 300zł)!

Kliknij tutaj i odbierz zniżkę na kurs!Start PLC programming today!

Opinions from Students

FAQ

How can I sign up for the course?

Use the “Join the Course” button on this website or send us an inquiry at: contact@controlbyte.tech

Will I receive support from the instructors for this training?

Yes! We stay in touch with you through Discord channel – chat for participants, forums, and live meetings – webinars.

Will I receive a certificate upon completion of the training?

After submitting all projects from homework assignments and having them checked by the instructors, you will receive a certificate of completion for the training.

Will I need a PLC controller during the course?

No! In the course you will use advanced PLC simulator, so you won’t need a real PLC controller. The Factory I/O environment simulates automation systems such as conveyors, manipulators, actuators, robots, etc. The PLC controller’s operation is simulated using the Siemens S7-PLCSIM environment.

Do I need to purchase a license for Codesys software?

No! Codesys it is a free software.

What if it turns out that the course is not for me? Can I return the course?

You have 14 days to return the course, counting from the start date of the course. We guarantee a safe purchase.

Is the course suitable for me if I have no prior experience with programming?

Yes. This is a basic course, designed in such a way that even someone without any experience with PLC controllers will be able to learn programming in LAD/FBD language.

How long will I have access to this course?

Access to the course is lifetime! As long as the ControlByte company exists in the automation market.

What does an online course on the ControlByte platform look like?

You get access to video materials with lessons explaining programming concepts. Participants follow exercises according to guidelines from the videos.

They also have homework assignments to solve independently. Homework projects are uploaded to the portal, where instructors check the tasks and provide feedback.

I would like to purchase training for my company. I need an official offer.

Please send an email with the information needed for the offer. We will send the offer to the indicated address. Upon receiving the order, we will grant you access to the course. Payment can be made according to the agreed commercial terms.

contact@controlbyte.tech

Can I receive an invoice?

No problem, please send us an email.

contact@controlbyte.tech

What if I have a problem or something is unclear?

Send us e-mail: contact@controlbyte.tech

PLC Programming course in text language ST

WITH 14-DAY RETURN GUARANTEE