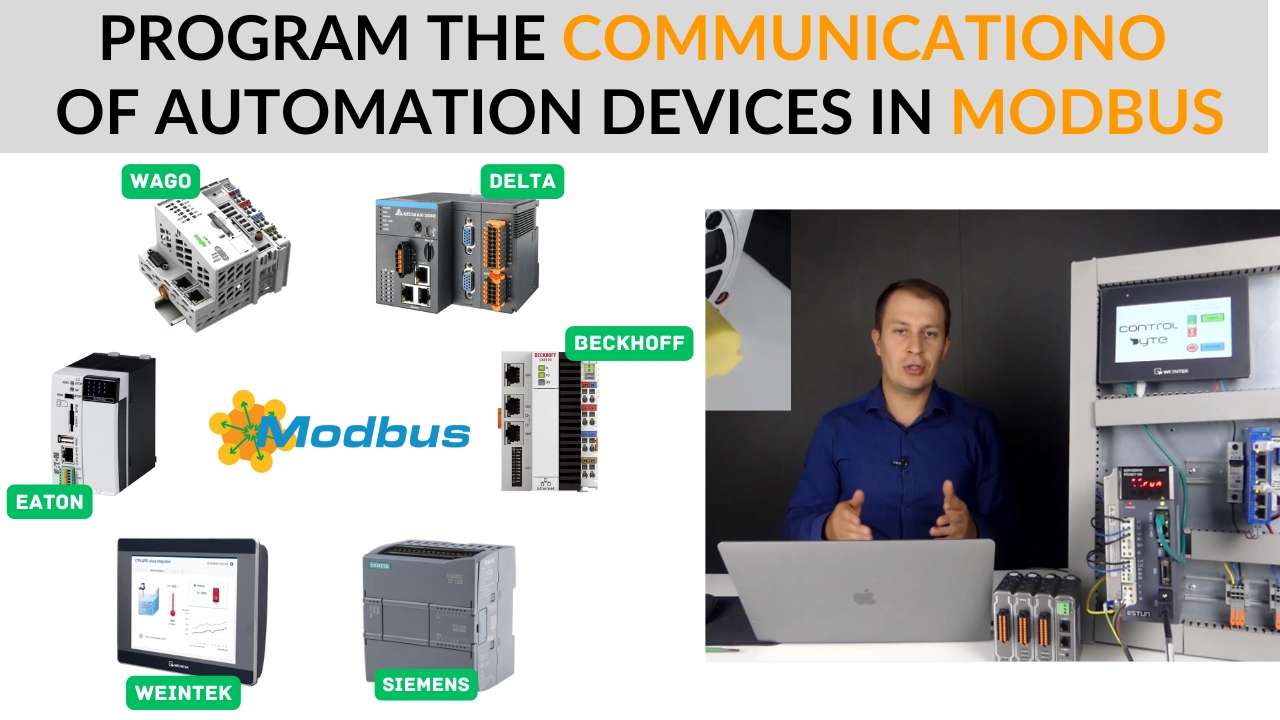

Modbus, Profinet, OPC UA Communication Training

You will program PLC communication in various industrial protocols, check what you will learn!

⏰Registration closes: Thursday, March 12th, 2026

Time left until the end of registration at a discounted price:

Video lessons

79

Duration

+15 hours

Skill Level

Intermediate

Students

368

Rating

4.9/5

Certificate Issued By

ControlByte

Trusted by Industry Leaders to Train Their Teams

What makes PLC ControlByte courses so popular?

-

You get access to video lessons on the e-learning platform.

-

You perform programming exercises based on provided project templates. All you need is your PC and a simulator!

-

You can take the training whenever and wherever you want. You can start the training at a later date.

-

You will have homework assignments to complete on your own!

-

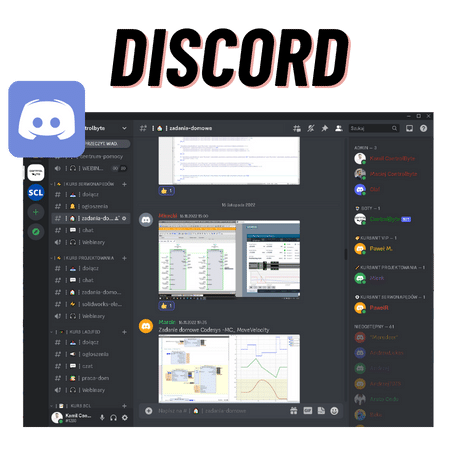

You receive course support through Discord chat and live meetings.

Course Content

79 lessons – 14 hours 54 minutes

1. Introduction

Introduction to the Course

0:57

Invitation to Discord

1:42

Which Simulators Will You Use?

0:53

Codesys Installation

3:25

Modbus TCP View Installation

0:47

Node-Red Installation

2:03

Launching Node-Red

8:08

Exercise: Writing to Modbus Coils (Write Multiple Coils)

3:05

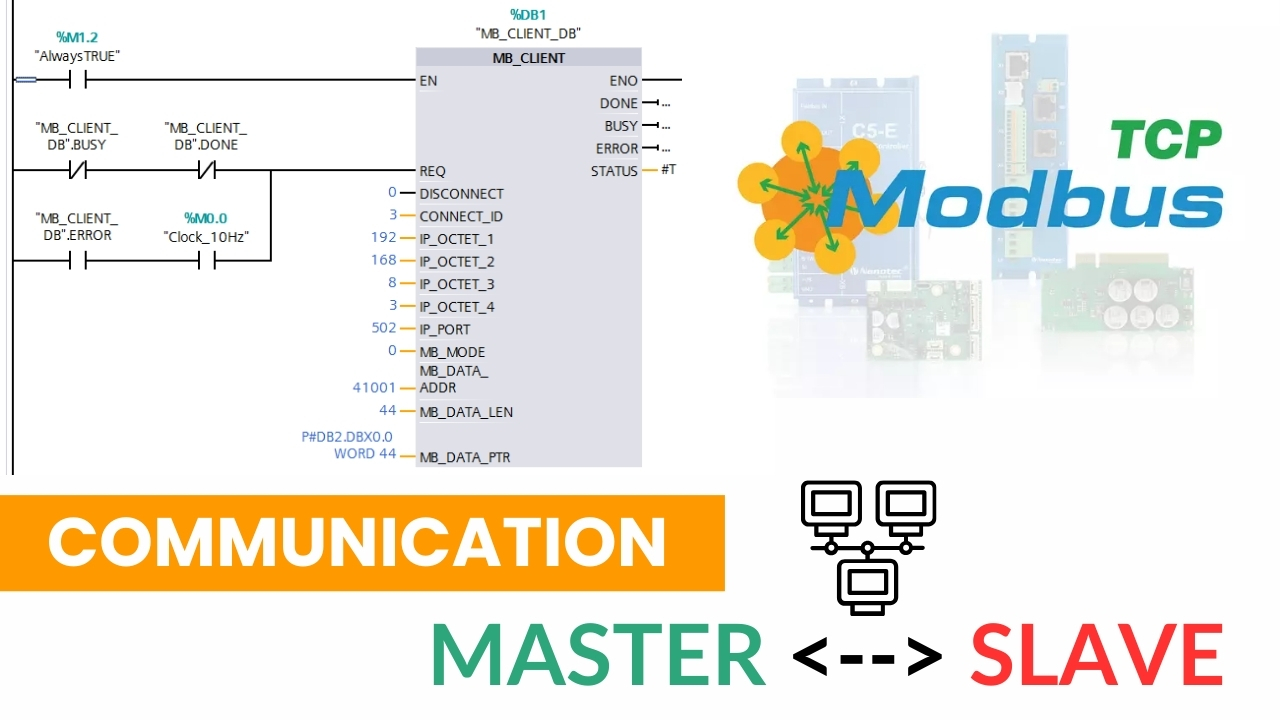

2. Modbus TCP Master on Siemens PLCs (S7-1200, S7-1500)

Installing TIA Portal and PLCSIM Advanced

3:37

Modbus TCP Programming for Siemens S7-1500 – Launching Node-Red and PLCSIM

18:15

Modbus TCP Programming for Siemens S7-1500 – Configuring the MB_Client Block

20:35

Parameterization of MB_MODE, MB_DATA_ADDR, and MB_DATA_LEN Based on the Modbus Device Memory Model

26:19

Programming a Sequence to Read Registers with Function 3 (Read Holding Registers) and Write with Function 15 (Write Multiple Coils) for Controlling the I/O Module

25:33

Programming Alarms and Diagnostics for Modbus Master – MB_Client

12:50

Implementation of Communication with Multiple Modbus Servers

19:05

Programming a Function Block for Communication with Multiple Modbus Servers

19:48

3. Modbus TCP Server on Siemens PLCs (S7-1200, S7-1500

Modbus TCP Server on Siemens PLC – First Startup

15:30

Modbus TCP Server on Siemens PLC – Configuring Access to Input, Output, and Holding Register Memory

12:20

Modbus TCP Server on Siemens PLC – Programming Access for Multiple Modbus Clients

18:04

4. Modbus RTU Master on Siemens PLCs (S7-1200, S7-1500)

Connecting the RS485 Converter and Testing Modbus RTU with the QModMaster Application

11:07

Programming the Modbus_Comm_Load Block – Initializing the RS485 Interface

13:22

Programming the Modbus Master with the Modbus_Master Block

20:50

5. Bonus: Modbus RTU Communication with Lenze i550 Inverter and Siemens S7-1200

Modbus RTU Communication, Lenze i550 Inverter, Siemens S7-1200 PLC

1:31:10

6. TCP and UDP Communication with Siemens PLCs (S7-1200, S7-1500)

TCP Communication with Siemens PLC

17:04

Bidirectional TCP Communication Between S7-1500 PLC and Node-Red (TRCV_C, TSEND_C)

20:13

7. TCP Communication: Siemens PLC -> ABB Robot Using XML Standard

Setting up the Project for TCP Communication between Siemens PLC and ABB Robot Using XML

15:42

Siemens PLC -> ABB Robot Using the XML Standard – LStream Library

14:39

8. TCP Communication: Hose Crimping Machine -> Siemens PLC Using XML Standard

Preparing the Project for Hose Crimping Machine -> Siemens PLC Communication Using XML (15:45)

15:45

Programming the XML Structure in TIA Portal

16:53

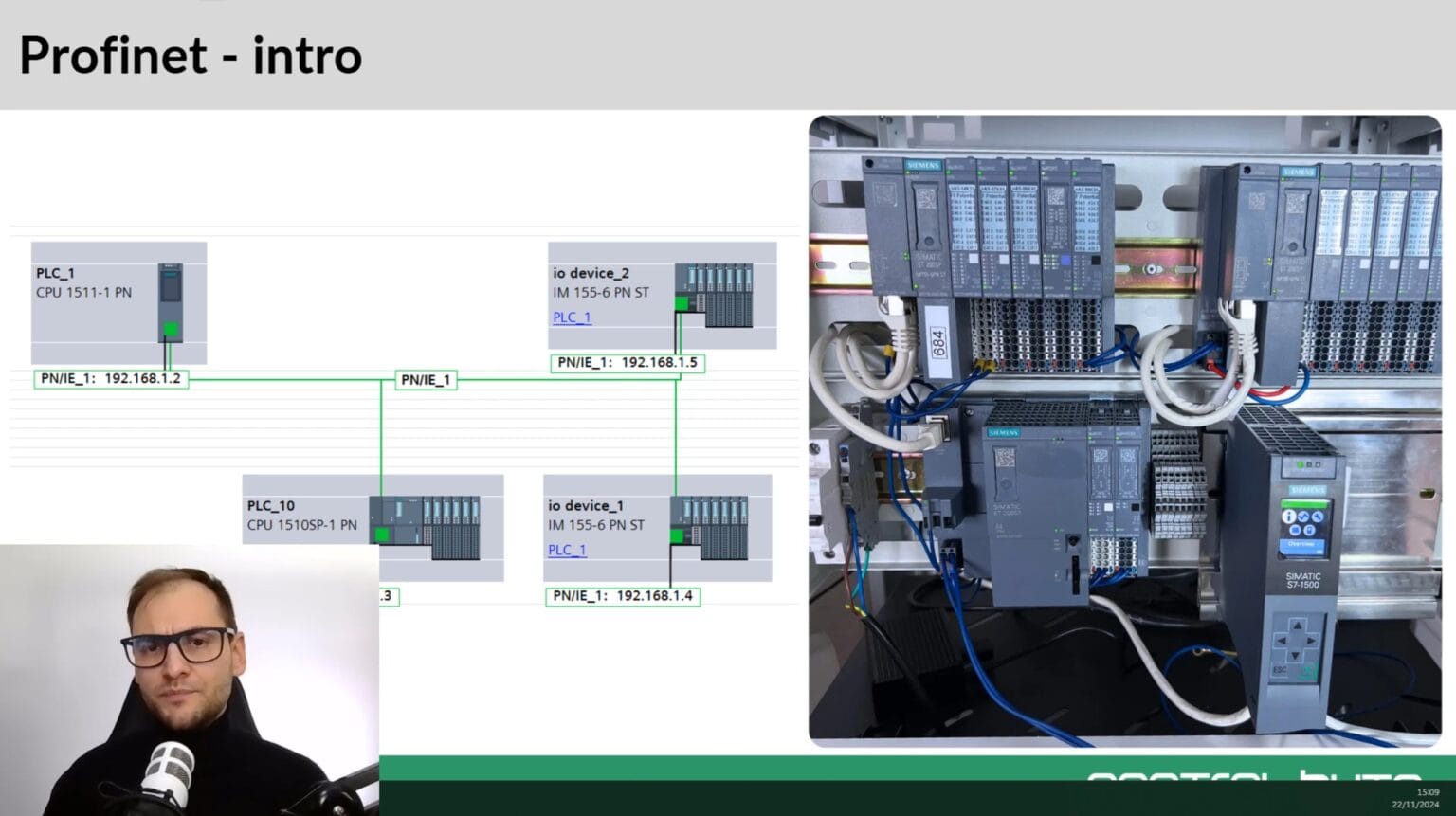

9. Profinet IO – Basics and Configuration

Introduction to Profinet

2:40

Searching Ethernet Network in TIA Portal – MAC and IP Addresses

17:29

Adding Devices to the Project – Network View: CPU S7-1500, ET200SP IO Modules

9:24

Profinet Name and Device Number

14:04

IO Device Configuration, Network Search

15:56

Network Topology Configuration – What is it? Introduction to Proneta

10:17

CPU-to-CPU Communication Configuration (iDevice) Between Separate TIA Portal Projects

15:04

Missing Hardware in the Library! How to Download GSDML Files from Siemens (HSP)?

7:34

Installing GSDML Files from Third-Party Hardware Manufacturers

7:18

10. Profinet – S7-1200 PLC Communication with Sinamics V90 in RT Mode

Configuring Profinet Communication between S7-1200 PLC and Sinamics V90 in RT Mode Using V-Assistant

15:12

Configuring Profinet Communication between S7-1200 PLC and Sinamics V90 in RT Mode in TIA Portal

25:10

11. Profinet – S7-1500 PLC Communication with Sinamics V90 in IRT Mode

Configuring Profinet Communication between S7-1500 PLC and Sinamics V90 in IRT Mode

13:43

12. Profinet – S7-1200 PLC Communication with Lenze i550 Inverter (Acyclic Communication)

Configuring Profinet Communication between S7-1200 PLC and Lenze i550 Inverter (Acyclic Communication)

19:25

13. Profinet IO – Diagnostic Tools: Proneta, TIA Portal, HMI Tools, Webserver

Introduction to Profinet IO Diagnostic Methods

9:53

Profinet IO Diagnostics – LED Indicators and Displays

6:57

Profinet IO Diagnostics – TIA Portal

8:31

Profinet IO Diagnostics – Webserver

7:17

Profinet IO Diagnostics – HMI Panel

4:19

Profinet IO Diagnostics – Proneta

9:12

14. Modbus TCP in Codesys

Codesys Modbus Configurator (Write Single Coil)

7:12

Codesys Modbus Configurator – Task (Function 5)

2:04

Codesys + Universal Modbus Library

1:16

Universal Modbus Library + Node-Red

10:52

Homework: Modbus Library + Output Sequence

7:20

Solution: Modbus Library + Output Sequence

3:05

Codesys Modbus TCP + Weintek HMI + Float Variable

7:37

Homework: Codesys + Weintek HMI + Float Variable

2:24

Task Solution: Float Variable

1:50

Modbus Diagnostics Codesys Configurator

10:02

Wireshark – Diagnostic Tool

6:28

Homework: Multiple Modbus TCP Devices in Codesys

9:56

15. Codesys OPC UA Communication

Codesys OPC UA Server – UA Expert

6:02

Codesys OPC UA – Task

00:59

Python Installation

2:28

Python Libraries Installation

1:27

VS Code Installation

1:16

Codesys OPC UA Server – OPC UA Client Python Script

18:19

Task – Python and Automated Testing of PLC Program via OPC UA

9:36

16. RS-232 Communication with Siemens S7-1200 PLC

RS-232 Communication with Siemens S7-1200 PLC

30:20

17. IO-Link Communication with Siemens PLCs

IO-Link Communication with Siemens PLCs, Turck IO-Link Master, Lenze i550 Inverter Protec

13:55

IO-Link Communication with Siemens PLCs, Turck IO-Link Master, Turck RGB KP50 Signal Light

13:59

IO-Link Communication with Siemens PLCs, Turck IO-Link Master, Turck UPROX Sensor

10:24

18. Broadcast/Multicast Communication in Codesys

UDP_Peer (FB)

20:12

19. Bonus #1: WAGO CC100

WAGO Modbus TCP Master + Opta Slave

15:11

WAGO + Opta Visualization and Tests

5:33

WAGO + Weintek Remote IO – WagoAppModbus Library

18:16

WAGO OPC UA Server

12:43

WAGO Modbus RTU Master – USB/RS485

5:22

WAGO + Weintek HMI

11:32

20. Bonus #2: Finder Opta

Finder OPTA and Weintek HMI Panel – Modbus TCP

14:11

Finder Opta Energy Consumption Measurement

18:00

Finder OPTA – Connection to Ignition SCADA

12:16

21. Bonus #3: Remote Access to Machines and Devices

IXON + PLC WAGO

7:12

“Discover communication in automation and learn to program PLC controllers, even if you’re just starting out. With a carefully planned learning path, you’ll acquire practical skills that will help you master key technologies like Modbus, Profinet, and recording PLC data to SQL databases.”

Kamil Biedulski

M.Sc. in Automation and Robotics, graduate of Wrocław University of Science and Technology

-

He gained his first experience in the maintenance department. Later, he worked in a machine design office.

-

Currently, he runs his own integration company. He designs and programs control systems for machines and robotic stations in the automotive and wood processing industries.

-

He has trained over 1,000 automation engineers in PLC and servo drive programming.

What will you get after enrolling in this course?

-

Over 79 practical video lessons (more than 15 hours)

-

You will test communication in a PLC simulator

-

You will receive project templates for Siemens and other devices

-

Devices: WAGO, RPi, Finder, Weintek

-

Instructor support via Discord chat and live meetings

-

You will have homework assignments to complete on your own!

-

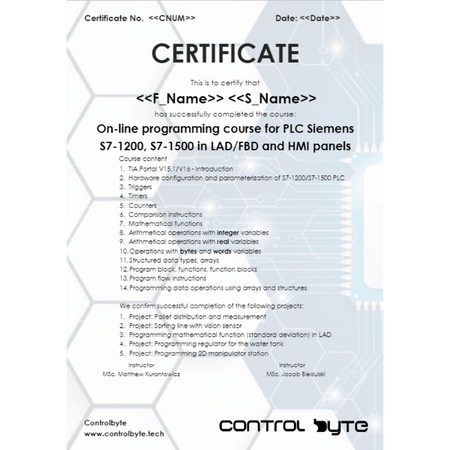

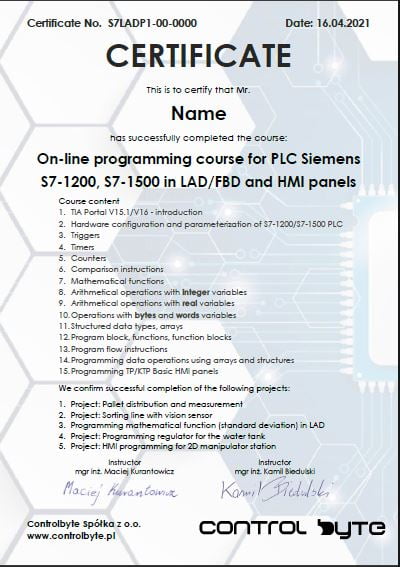

Certificate of course completion in Polish and English.

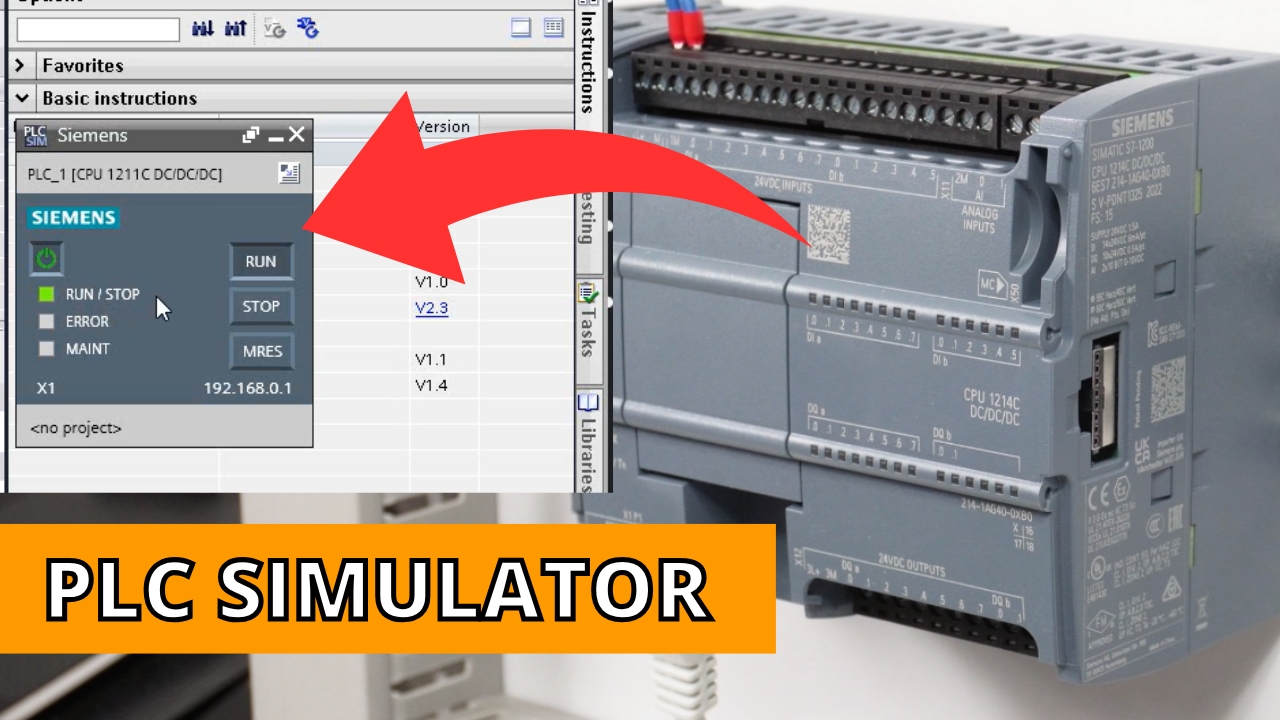

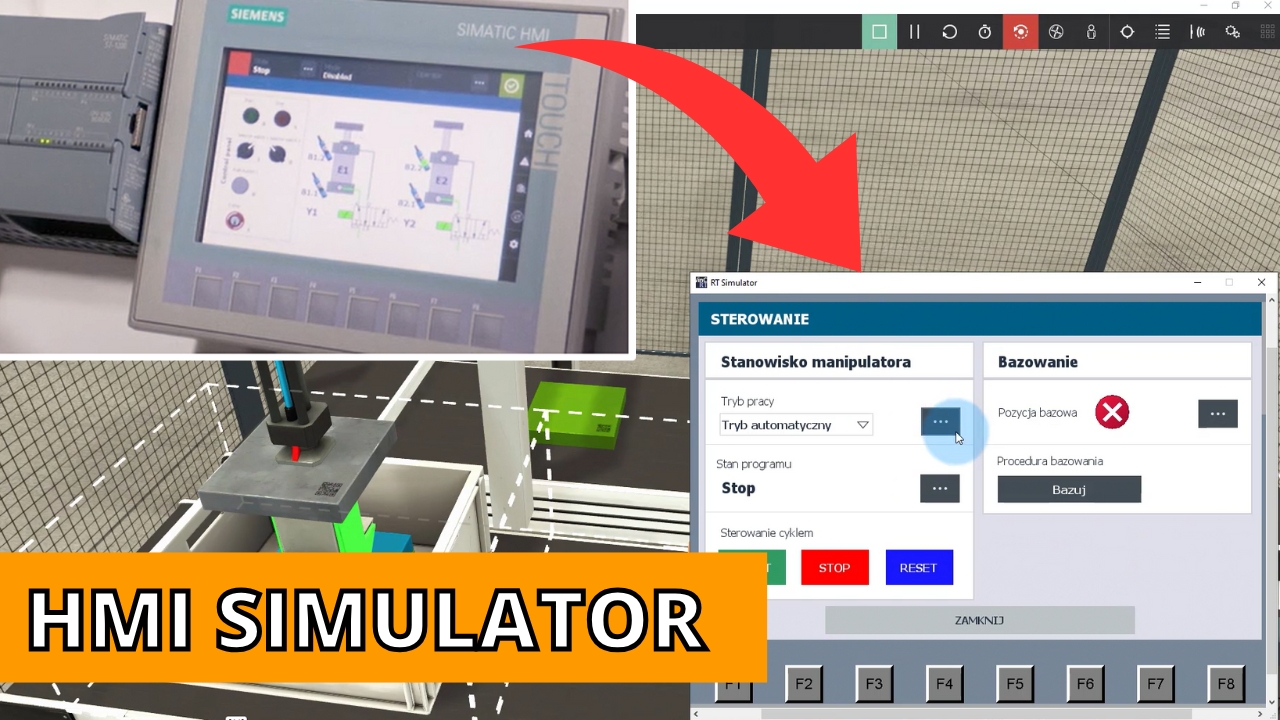

PLC Controller Simulator S7-1200/S7-1500

-

In the course, you will use PLC simulators (Siemens + Codesys)

-

We will show you how to install and set it up

-

The PLC simulator is free and fully functional!

-

We also demonstrate how to work with real hardware

-

You will learn about free Modbus communication simulators

Siemens HMI Panel Simulator

-

You don’t need physical hardware to complete the course

-

All functionality will be programmed on the PLC simulator and communication simulation tools

-

On your PC, you can freely test communication with panels and even SCADA systems!

-

The PLC simulator is free and fully functional!

Modbus RTU

Module Content:

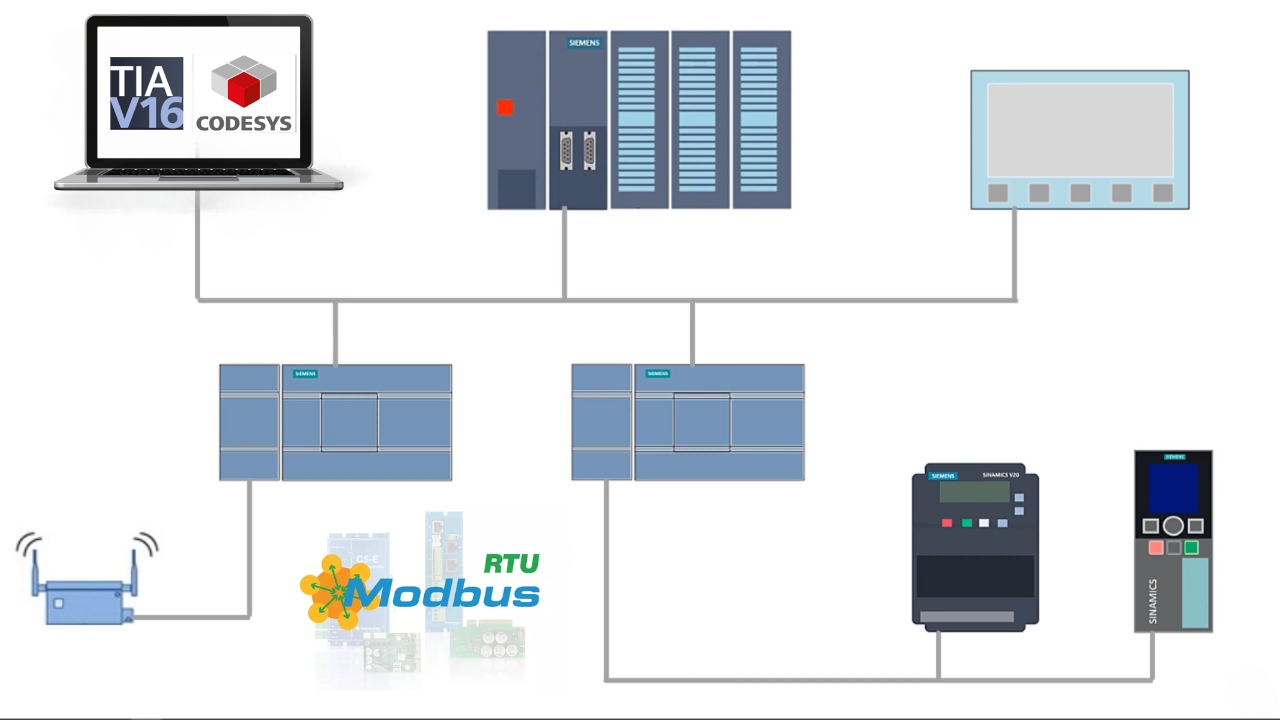

Modbus TCP

Module Content:

-

What is Modbus TCP

-

Sending a Communication Frame – MODBUS TCP

-

Simulator: MODBUS TCP Query and Response

-

What Network Structure for Modbus TCP

EtherCAT protocol

Module Content:

-

HMI Weintek <–> Servo Drive via EtherCAT

-

Lenze Inverter <–> Codesys

-

Inovance Multi-Axis Drive <–> Codesys

-

Homework Assignment for Independent Completion

Profinet Communication

Module Content:

-

What is Profinet Communication

-

Siemens PLC <–> HMI Communication

-

Siemens PLC <–> Inverter Communication

-

Siemens PLC <–> SCADA Communication

-

How to Add Multiple Devices in the Profinet Standard

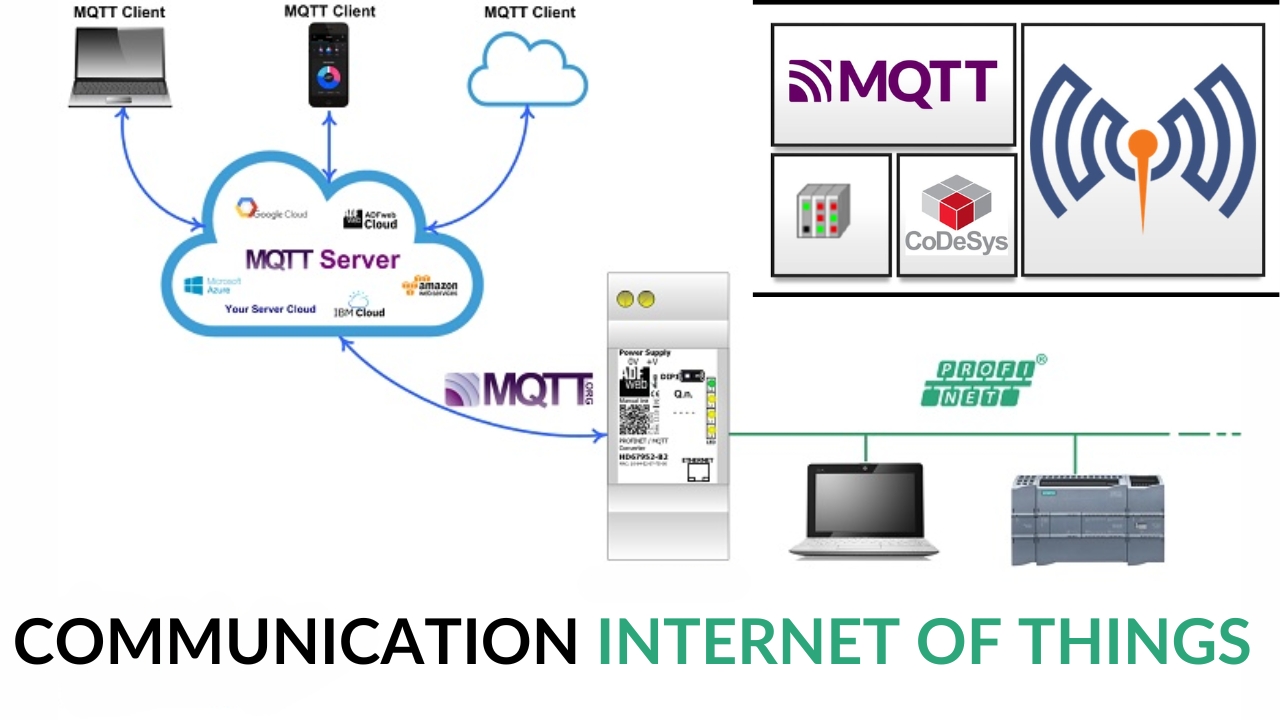

MQTT

Module Content:

-

M2M Communication (Machine to Machine)

-

Subscriber <–> Broker <–> Publisher Data Exchange

-

Practical Communication in Codesys

- MQTT for WAGO, RPi, Siemens, PLCnext

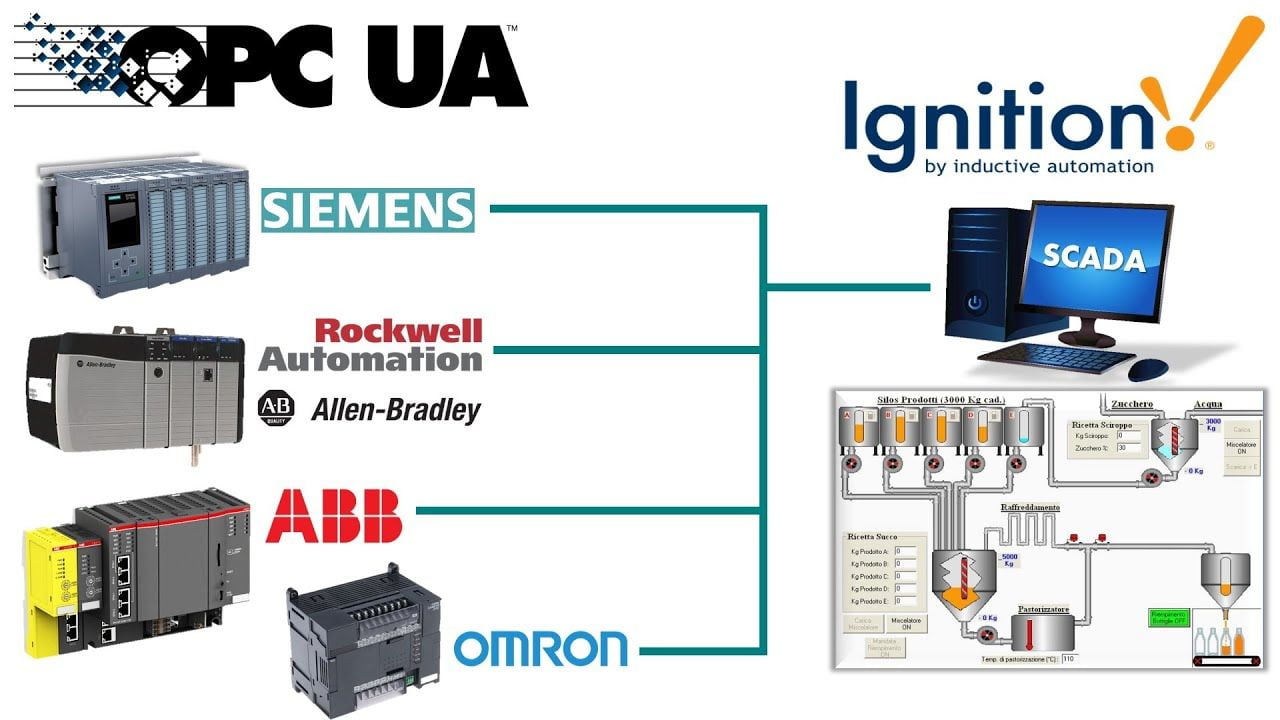

OPC UA Communication

Module Content:

-

Standardization of OPC UA Communication

-

OPC UA Server <–> OPC UA Client Communication

-

WAGO PLC <–> UA Expert Simulator Communication

-

Homework Assignment for Independent Completion

Remote Access to Machines and Devices

Module Content:

-

How to Program PLCs Remotely?

-

Establishing a VPN Connection with PLC

-

HTTP, FTP, SSH Protocols

-

Homework Assignment

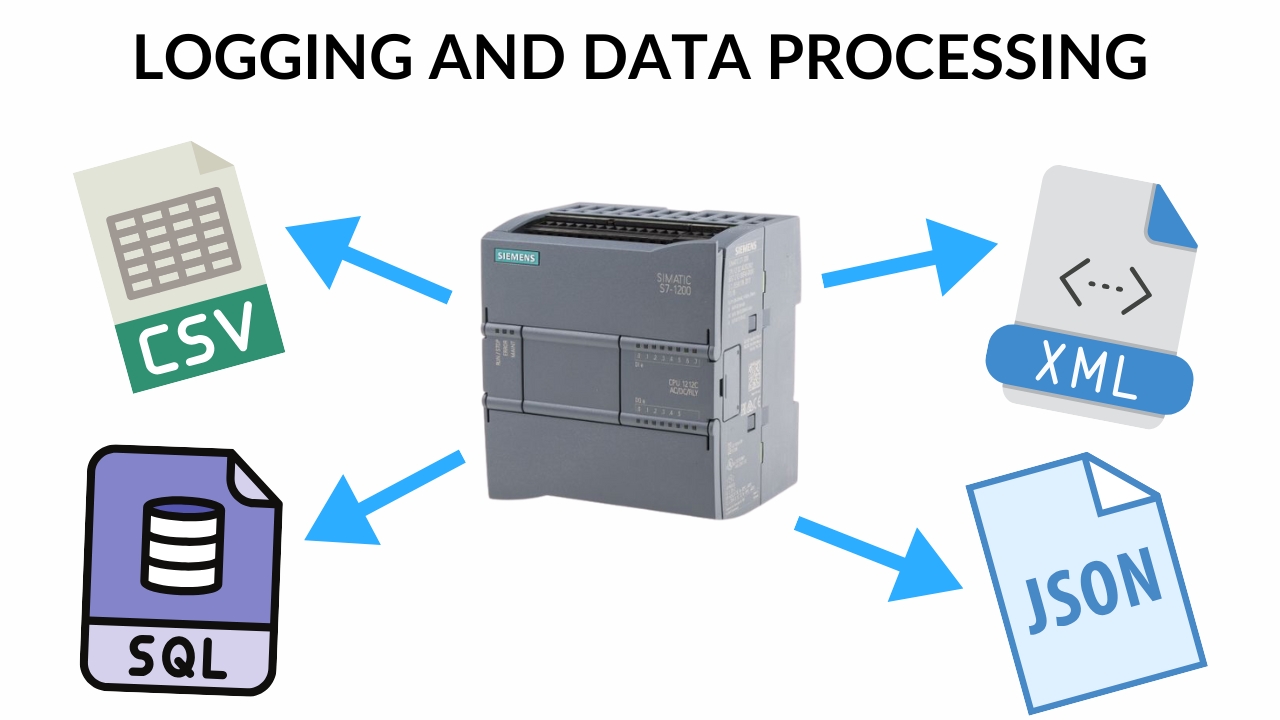

Data Processing and Archiving

Module Content:

-

CSV – Writing and Reading to a File

-

XML, JSON – File Formatting

-

Saving Data from PLC to an SQL Database

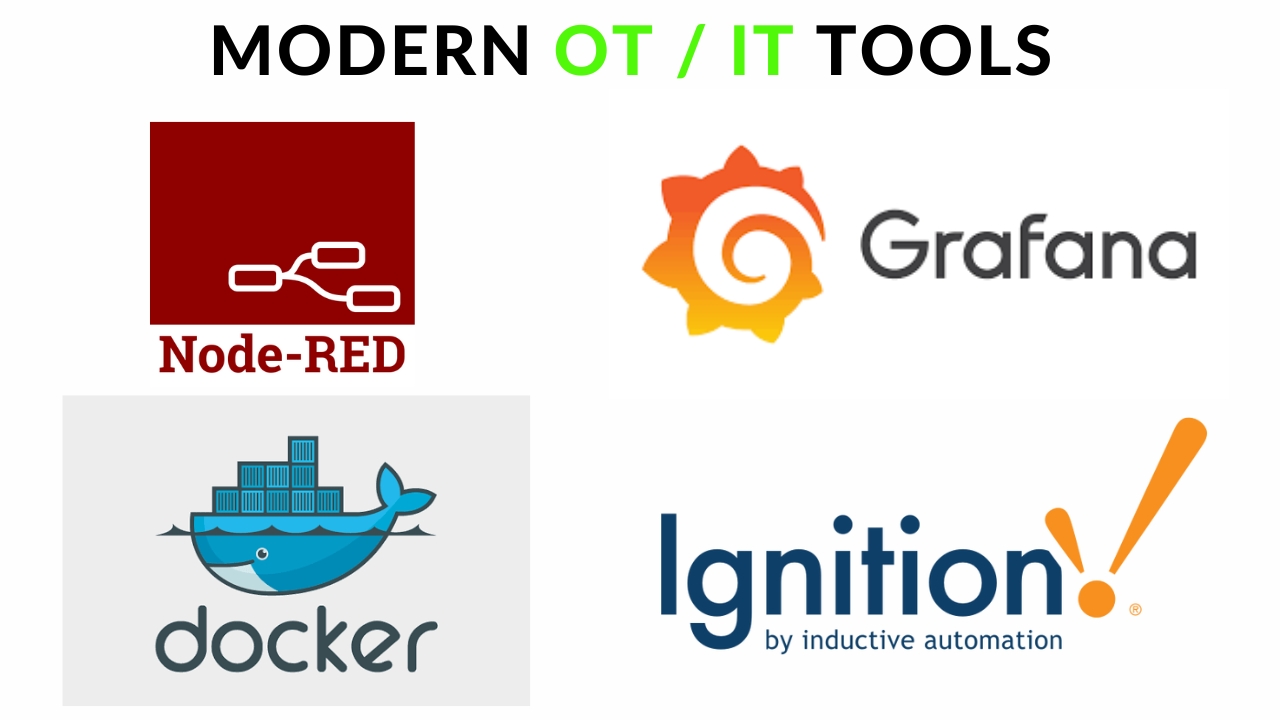

Modern OT/IT Tools

Module Content:

-

Node-RED – Browser-Based Programming

-

Grafana – Modern Visualization

-

SCADA Ignition

-

Docker – Application Containers

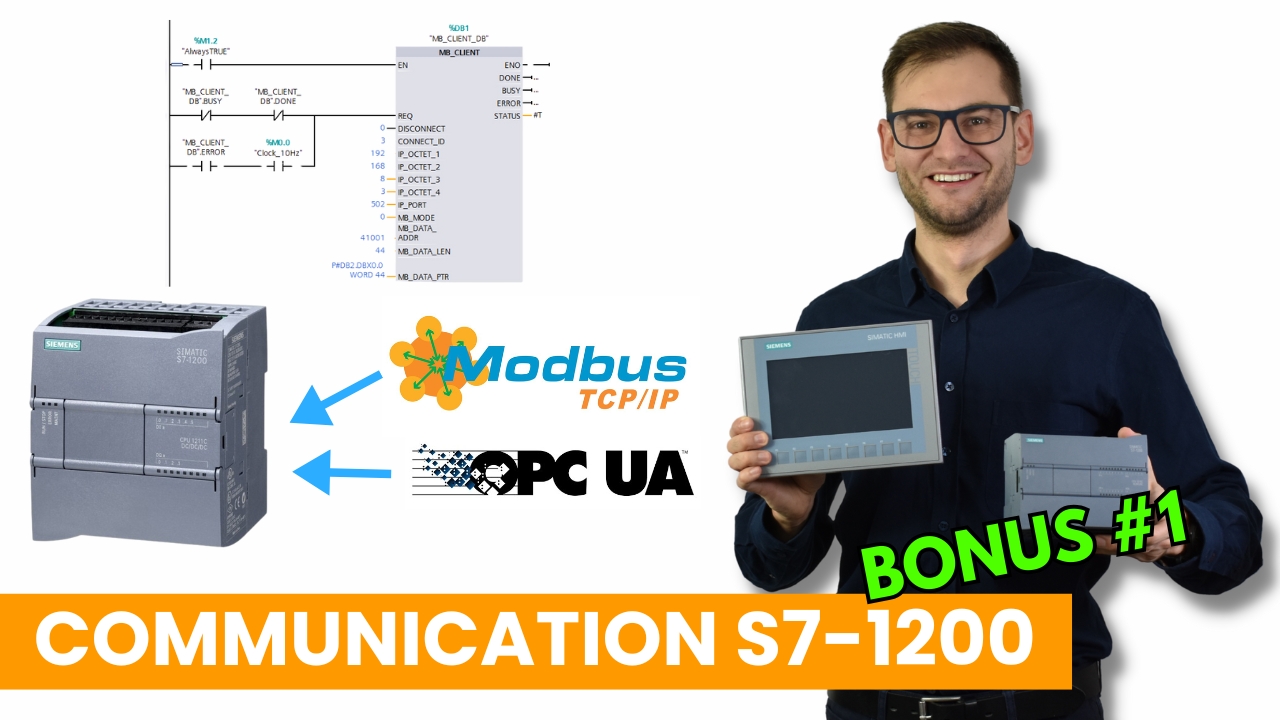

Bonus #1: Siemens Communication

Module Content:

-

Siemens S7-1200 Communication

-

Modbus RTU, Modbus TCP IP – Blocks in TIA Portal

-

OPC UA – Communication with SCADA

-

S7-1500 Communication

-

Homework Assignment

Bonus #2: WAGO Communication

Module Content:

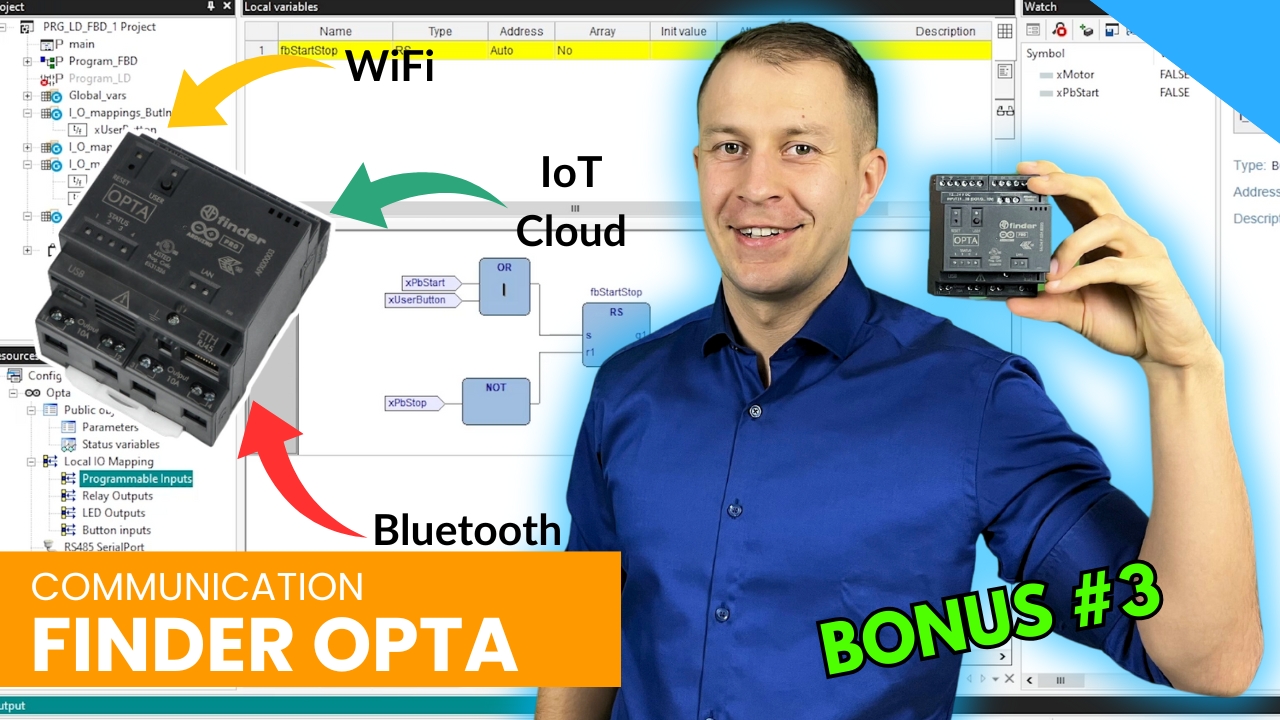

Bonus #3: Finder Opta Communication

Module Content:

-

WiFi Connection with Controller

-

Bluetooth Communication

-

Modbus, MQTT

Why you should join this course?

-

You gain a skill highly valued by employers.

-

You can showcase your certificate on LinkedIn, Goldenline, and of course on your CV!

-

If you want to change your job and pursue a career as an automation engineer, you are in the right place!

-

Hundreds of students have already taken this learning path, ask around what they say about us in the industry!

-

You get lifelong access to the course materials on our platform. You can revisit them whenever you want.

-

You will test all your written code in a virtual factory in Factory IO.

-

You do not need any equipment for the course. A PLC simulator and Factory IO are enough. The code you write can be used in real-life projects.

-

Hundreds of students have already taken this learning path, ask around what they say about us in the industry!

-

You receive course support through Discord chat and live meetings.

-

We will provide you with your code reviews by Discord channel!

-

You can chat with other aspiring PLC programmers!

-

You can showcase your certificate on LinkedIn, Goldenline, and of course on your CV!

-

You can get better job!

-

You can start working as PLC programmer

Training price

Before I show you the price, see exactly what you will get by joining the LAD/FBD course:

Educational materials, over 70 video lessons explaining communication and data processing in industrial and building automation. Through video materials, we will guide you step by step from simple concepts to advanced projects.

Value: 200€

Tasks to complete on your own – you will need to show creativity! Not everything in the course will be shown directly! For some solutions, you will have to figure it out on your own.

Value: 50€

Analysis of your homework – feedback from instructors. We review your homework and provide comments to help improve your programs!

Value: 100€

Contact with instructors through the e-learning platform and Discord. Feel free to write if you have any issues! We will address your concerns in real time.

Value: 100€

Consultations in the form of weekly live webinars. You will be able to ask questions live and engage in discussions.

Value: 50€

Closed discussion forum for trainees. You will join the PLC programming community and be able to share your thoughts.

Solving problems through group work is much faster!

Solving problems through group work is much faster!

Value: PRICELESS

Satisfaction Guarantee – 14 days to return the product. We guarantee that you will be satisfied with participating in our course.

If you are not happy with our training, you have 14 days to return the product – we will refund the full amount for the course. So far, no one has returned any of our courses!

If you are not happy with our training, you have 14 days to return the product – we will refund the full amount for the course. So far, no one has returned any of our courses!

Value: PRICELESS

Proven educational path followed by over 1000 trainees. Our training program has already been completed by over 1000 automation engineers in previous editions.

Value: PRICELESS

Thanks to the proven formula of our training and cost optimization, you can purchase this training for:

400€

99€

📚 Buy now and save 301€!

Join now for 99€

Remaining time until the end of enrollment for the course

⏰Registration closes: Thursday, March 12th, 2026

Safe transaction and 14-day money back guarantee!

-

Secure Transactions: we assure that your transactions are safe and secure.

-

Trusted Payment Gateways: We partner with trusted payment gateways for a seamless payment experience – powered by Stripe and PayPal

-

14-Day Money Back Guarantee: Enjoy peace of mind with our 14-day money back guarantee.

-

Risk-Free Enrollment: Enroll with no risk and explore the course before making a commitment.

-

Customer Satisfaction: We prioritize your satisfaction and are here to support you.

-

Transparent Refund Process: Our refund process is simple and transparent.

-

Invest with Confidence: Secure your future with confidence in our PLC course.

Opinions from Students

FAQ

How can I sign up for the course?

Use the “Join the Course” button on this website or send us an inquiry at: contact@controlbyte.tech

Will I receive support from the instructors for this training?

Yes! We stay in touch with you through Discord channel – chat for participants, forums, and live meetings – webinars.

Will I receive a certificate upon completion of the training?

After submitting all projects from homework assignments and having them checked by the instructors, you will receive a certificate of completion for the training.

Will I need a PLC controller during the course?

No! In the course you will use advanced PLC simulator, so you won’t need a real PLC controller. The Factory I/O environment simulates automation systems such as conveyors, manipulators, actuators, robots, etc. The PLC controller’s operation is simulated using the Siemens S7-PLCSIM environment.

Do I need to purchase a license for Siemens TIA Portal software?

No! You only need a free license.

What if it turns out that the course is not for me? Can I return the course?

You have 14 days to return the course, counting from the start date of the course. We guarantee a safe purchase.

Do I need to purchase a license for Factory I/O software?

No! To participate in the course, a free license is sufficient.

Is the course suitable for me if I have no prior experience with programming?

Yes. This is a basic course, designed in such a way that even someone without any experience with PLC controllers will be able to learn programming in LAD/FBD language.

How long will I have access to this course?

Access to the course is lifetime! As long as the ControlByte company exists in the automation market.

What does an online course on the ControlByte platform look like?

You get access to video materials with lessons explaining programming concepts. Participants follow exercises according to guidelines from the videos.

They also have homework assignments to solve independently. Homework projects are uploaded to the portal, where instructors check the tasks and provide feedback.

I would like to purchase training for my company. I need an official offer.

Please send an email with the information needed for the offer. We will send the offer to the indicated address. Upon receiving the order, we will grant you access to the course. Payment can be made according to the agreed commercial terms.

contact@controlbyte.tech

Can I receive an invoice?

No problem, please send us an email.

contact@controlbyte.tech

What if I have a problem or something is unclear?

Send us e-mail: contact@controlbyte.tech

Course on Communication and Data Processing in Automation

WITH A 14-DAY MONEY-BACK GUARANTEE

PRICE:

400 €

99 €

Remaining time until the end of enrollment for the course

⏰Registration closes: Thursday, March 12th, 2026