This post is dedicated to the PROFINET network. I will cover two topics related to this network: the PROFIdrive standard and real-time communication modes – RT and IRT.

In the first part, I’ll describe the PROFIdrive Standard, focusing on Siemens controllers and drives. In the second part, you’ll learn about the types of communication in real-time mode.

1.1 PROFIdrive Standard

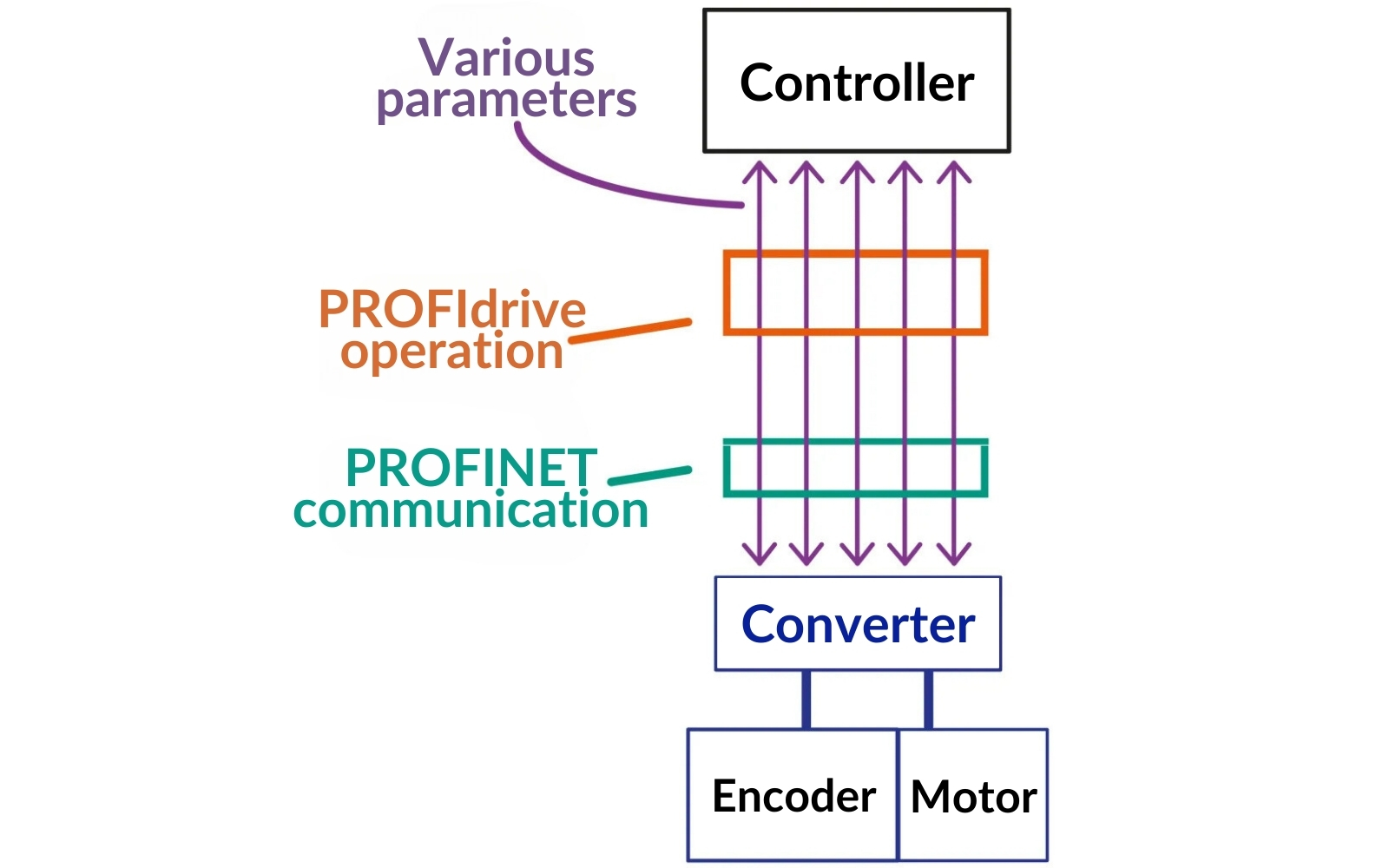

The prefix “PROFI” might remind you of PROFINET or PROFIBUS protocols. PROFIdrive standard uses these protocols for communication, but it is specifically designed for drives and encoders.

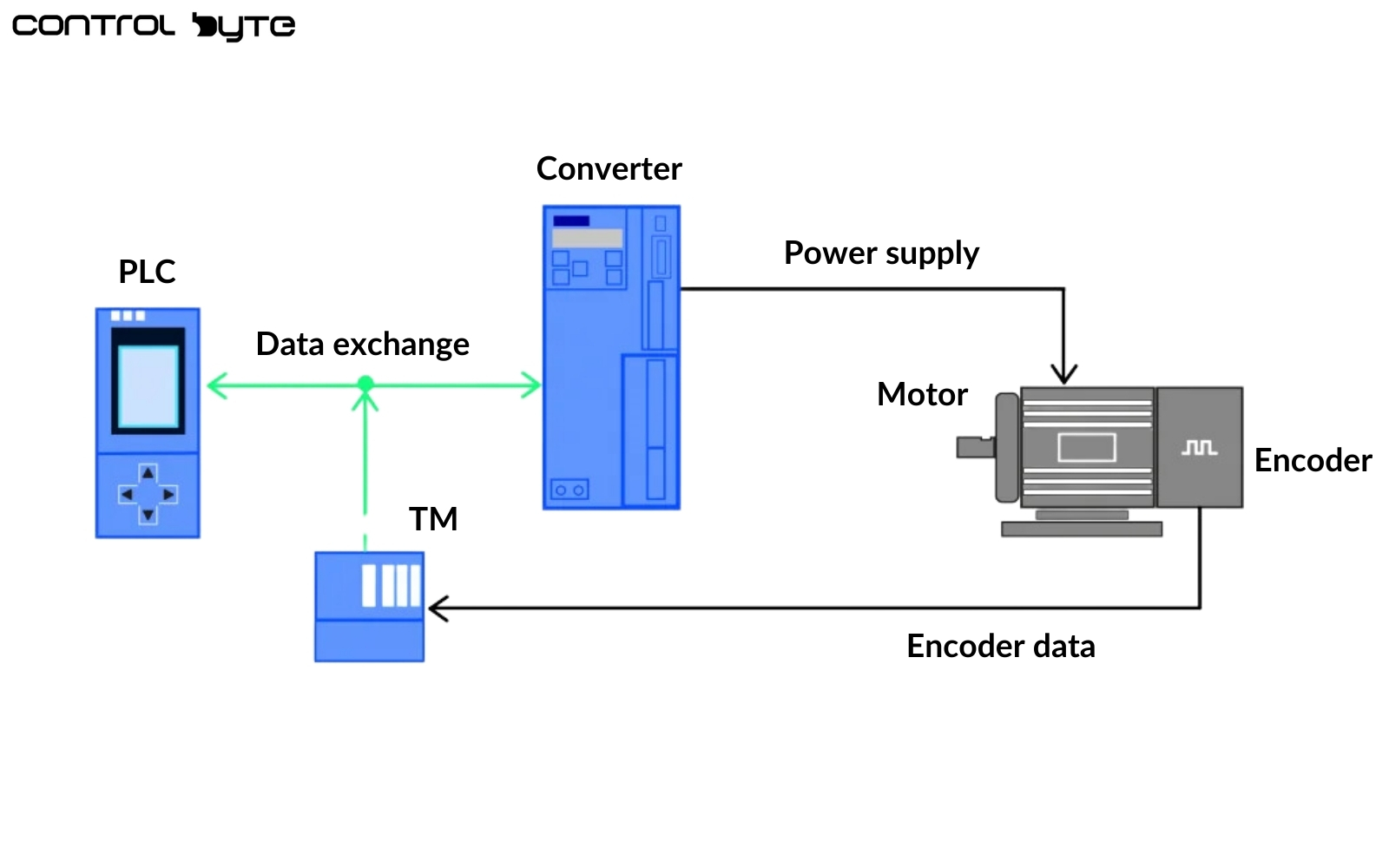

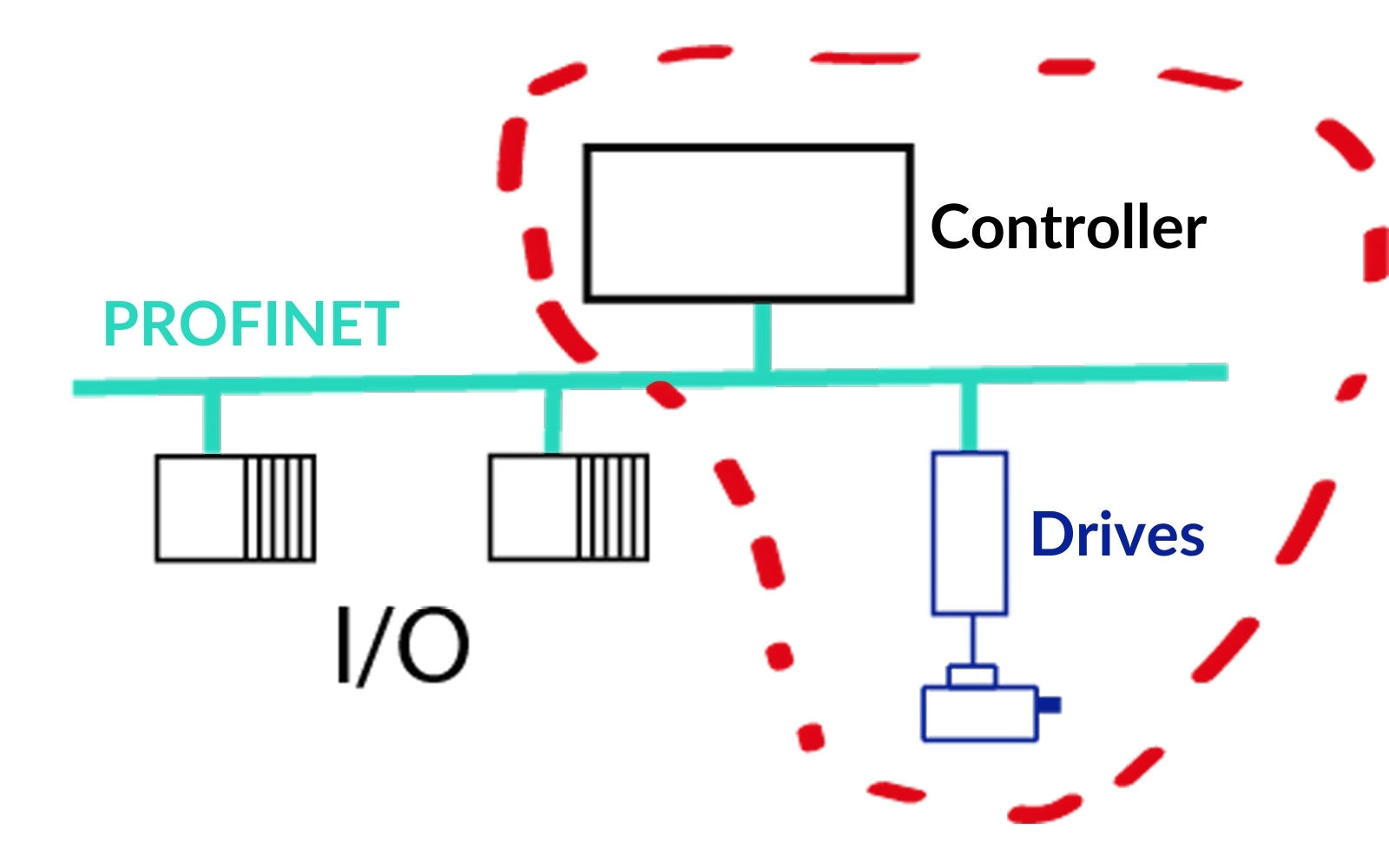

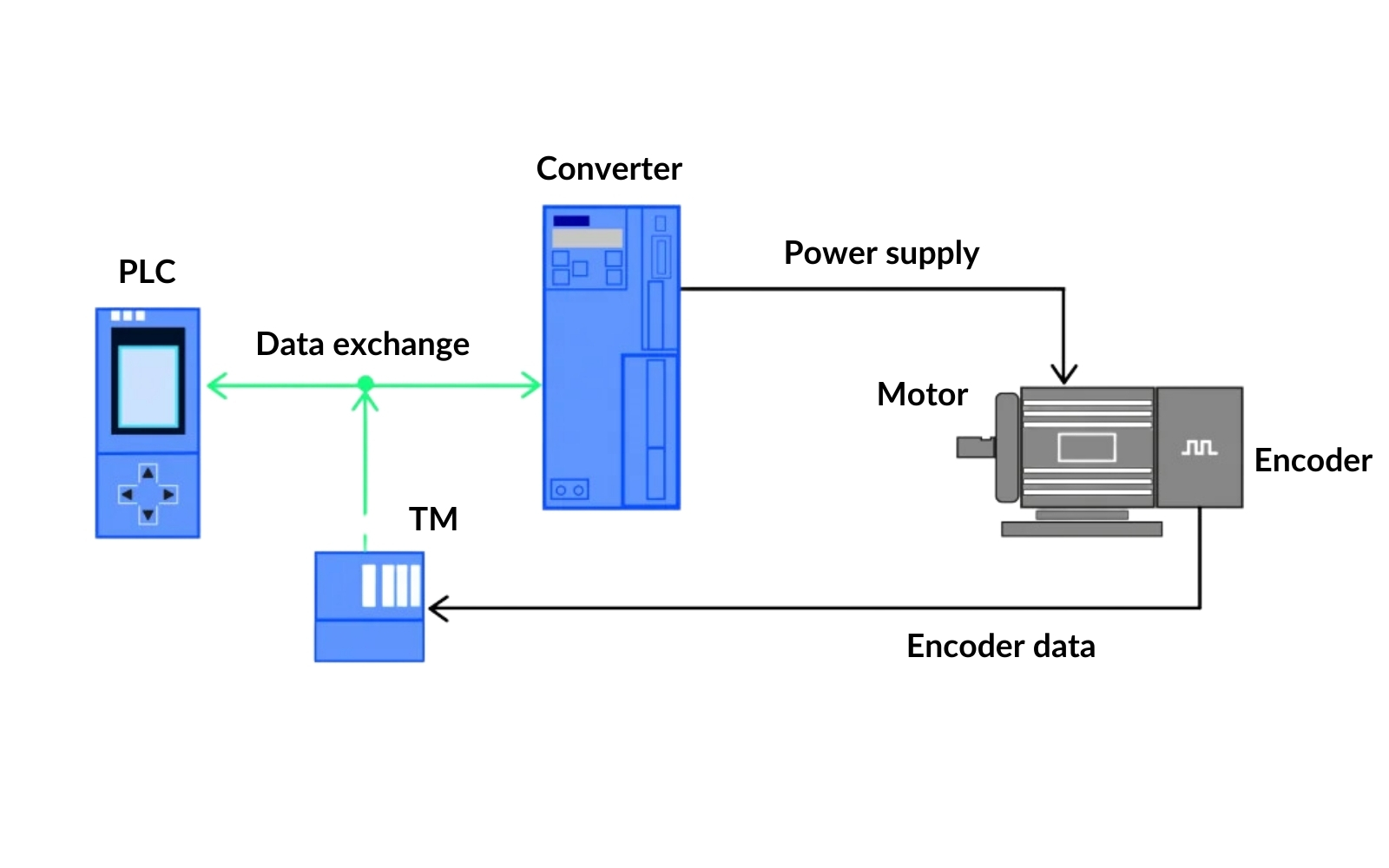

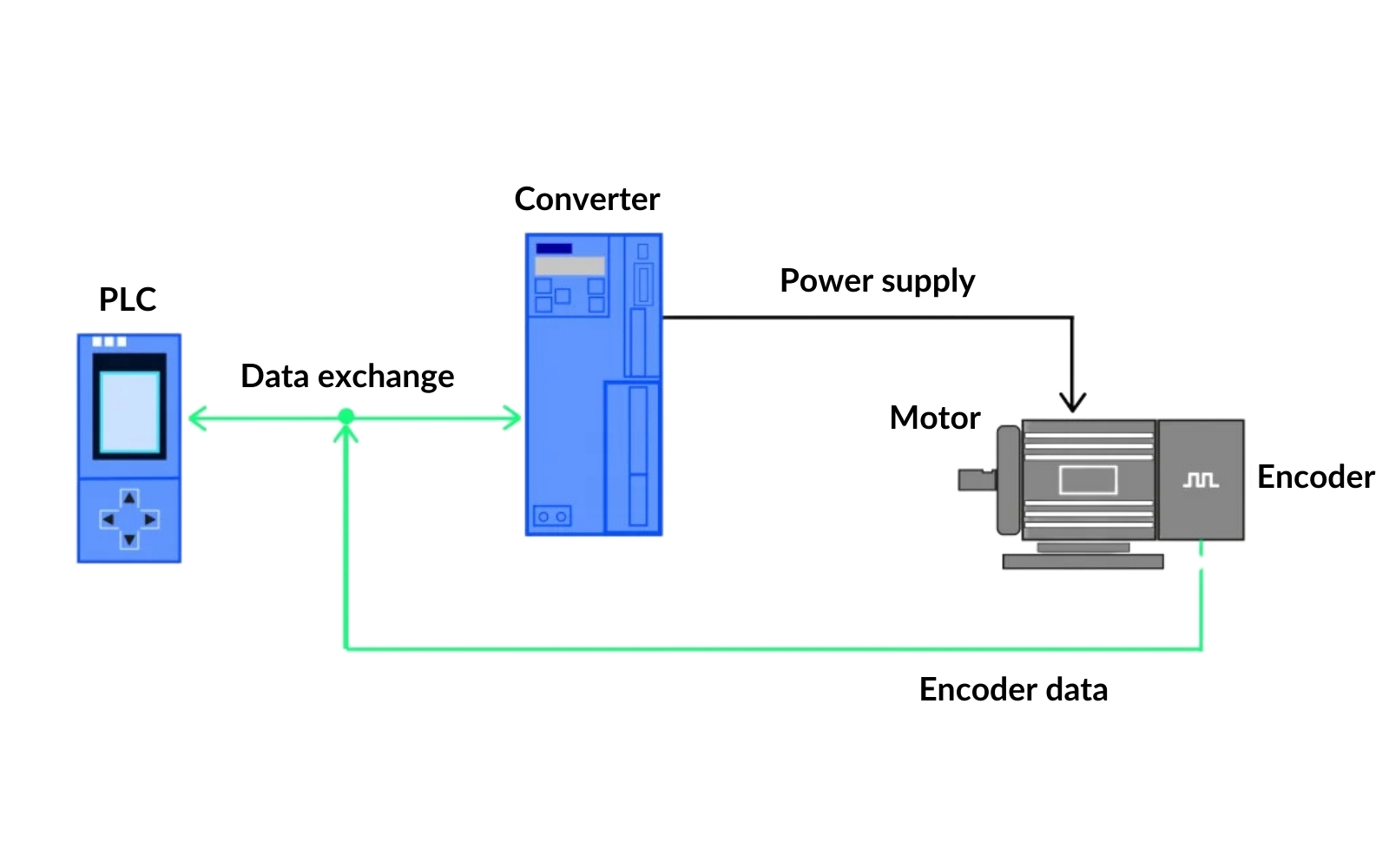

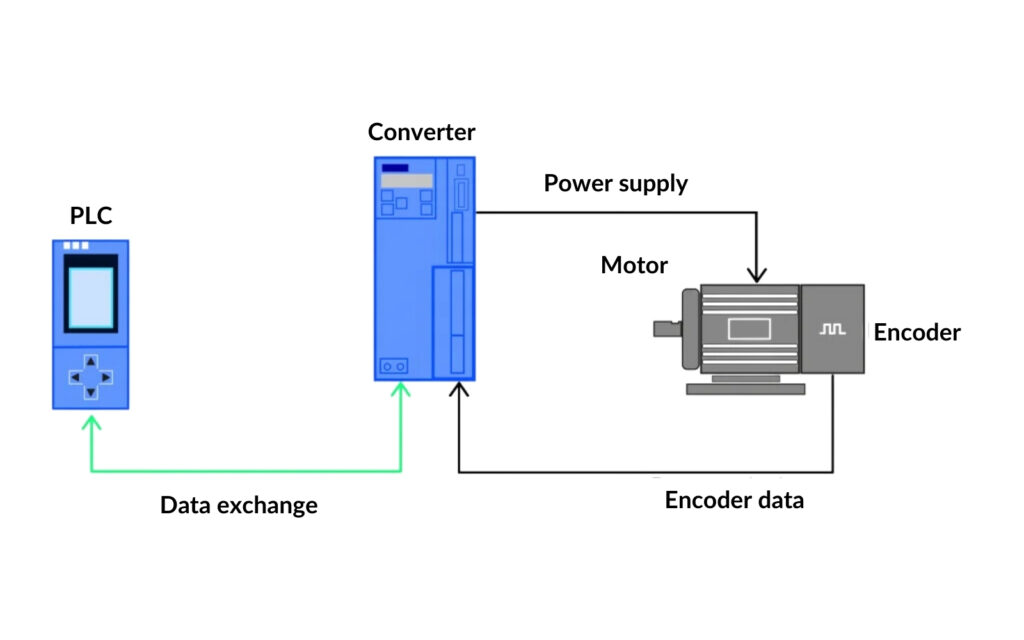

Let’s assume we have a simple setup of a controller, converter, motor, and I/O modules. They communicate via the PROFINET protocol. The red dashed line in the image below highlights the elements that PROFIdrive manages.

Communication involves sending so-called PROFIdrive frames, which include telegrams explained in more detail in the next section. Moreover, communication between the controller and the converter is bidirectional; in particular, the controller sends commands in frames while simultaneously receiving status information about the motor, along with current position values.

1.2 Telegrams – General Information

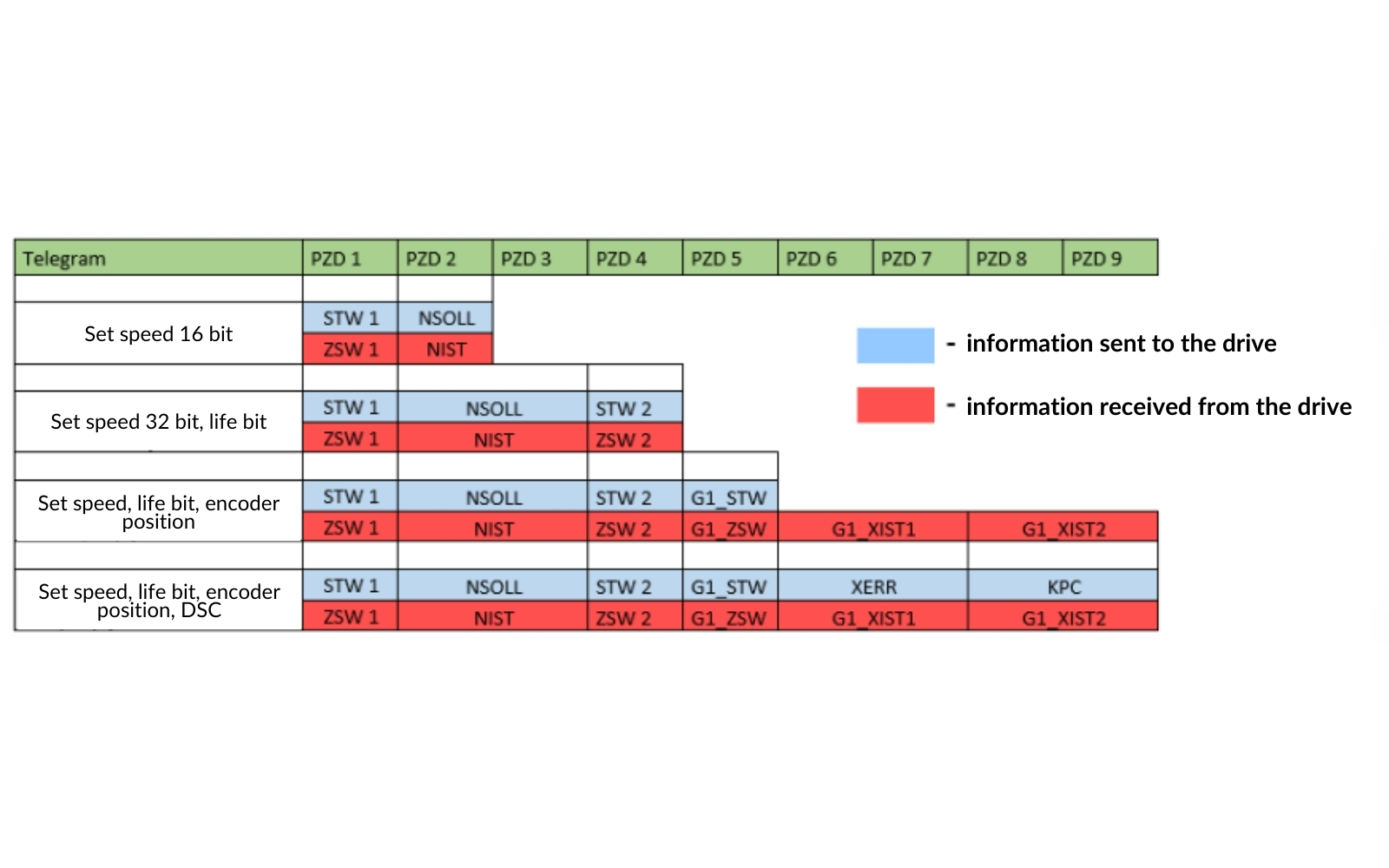

As previously mentioned, PROFIdrive frames include telegrams. A telegram is information sent to the converter as a “Process Data Word” – essentially a bit sequence. A single “Process Data Word” consists of 16 bits or 2 bytes. Below is a table illustrating what a Telegram is:

Fig. 3 Example Telegrams

“PZD” stands for the previously mentioned “Process Data Word.” As shown, a single Telegram can consist of multiple such words. On the left side of the table, basic Telegrams 1-5 in the PROFIdrive standard are displayed. Each of these Telegrams has different functions.

To better understand, below are the expanded abbreviations used in the table:

- STW – Control Word

- ZSW – Status Word

- NSOLL – Set Speed

- NIST – Actual Speed

- G1_STW – Control Word Encoder 1

- G1_ZSW – Status Word Encoder 1

- G1_XIST – Current Position Encoder 1

- XERR – Position Deviation

- KPC – Position Controller Gain

Information sent from the controller to the converter is a control signal. Information received from the converter includes, for example, the motor shaft’s speed and current position.

1.3 Basic Telegrams

You may wonder what determines the choice of a Telegram. The selection depends on the desired function – whether it should set and read the shaft speed or also transfer shaft position via an encoder.

Choosing the right Telegram is one part; hardware configuration is also important. Below are configurations for basic Telegrams 1-5.

The setup for Telegram 2 provides functions similar to those of Telegram 1, with the added feature of synchronizing the drive with the real-time clock.

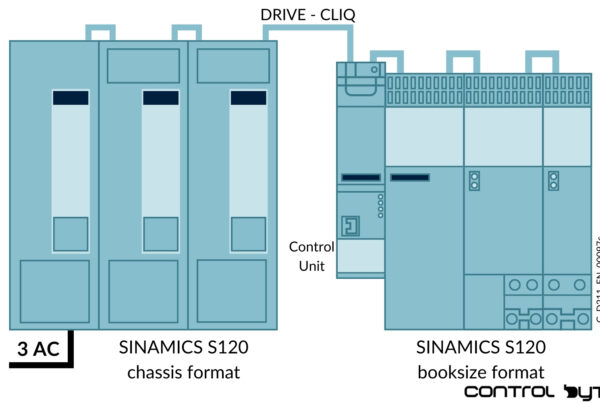

Telegram 3 and 5 are used for the hardware configuration shown in Fig. 6, with some differences in functionality.

- Functions of Telegram 3:

- Positioning axis, if the encoder is connected to the drive

- Real-time synchronization of the drive is possible

- Functions of Telegram 5:

- Positioning axis if servo drive is in Dynamic Servo Control mode

- Real-time synchronization of the drive is required

1.4 Status and Control Words

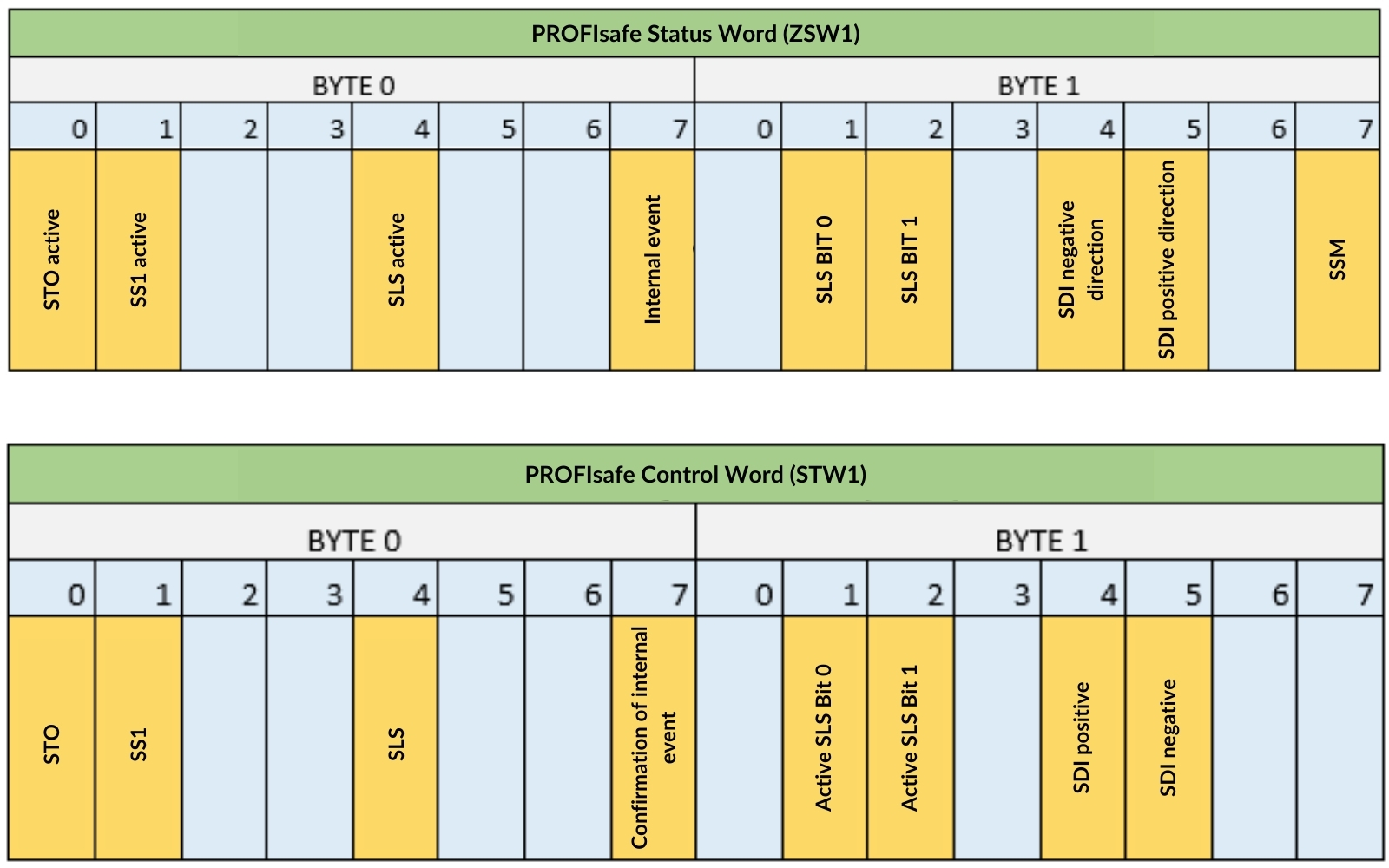

In section 2, we discussed STW and ZSW control and status words. These are components of every Telegram. To understand what they consist of, the following graphics are provided:

As shown, these are essentially bit sequences, with each bit representing a different value.

2.1 PROFINET IO Communication

PROFINET IO communication always operates in real-time mode, with a separate communication layer that functions independently from other processes. Additionally, RT (real-time) mode is prioritized over other data.

As mentioned earlier, there are two real-time modes: standard RT and isochronous IRT. Both operate on two different channels: cyclic and acyclic. Discussing these channels highlights the differences between RT and IRT modes. Below is a comparison of RT and IRT modes.

| vs | ||

|---|---|---|

|

|

Fig. 1 Differences Between RT and IRT Modes

As shown, the difference is subtle yet significant. To understand why, it is important to know the functions of cyclic and acyclic channels.

Moreover, the system precisely defines the reading and writing time of information in these modes, with operations occurring in cycles lasting several milliseconds.

2.2 Cyclic and Acyclic Channels

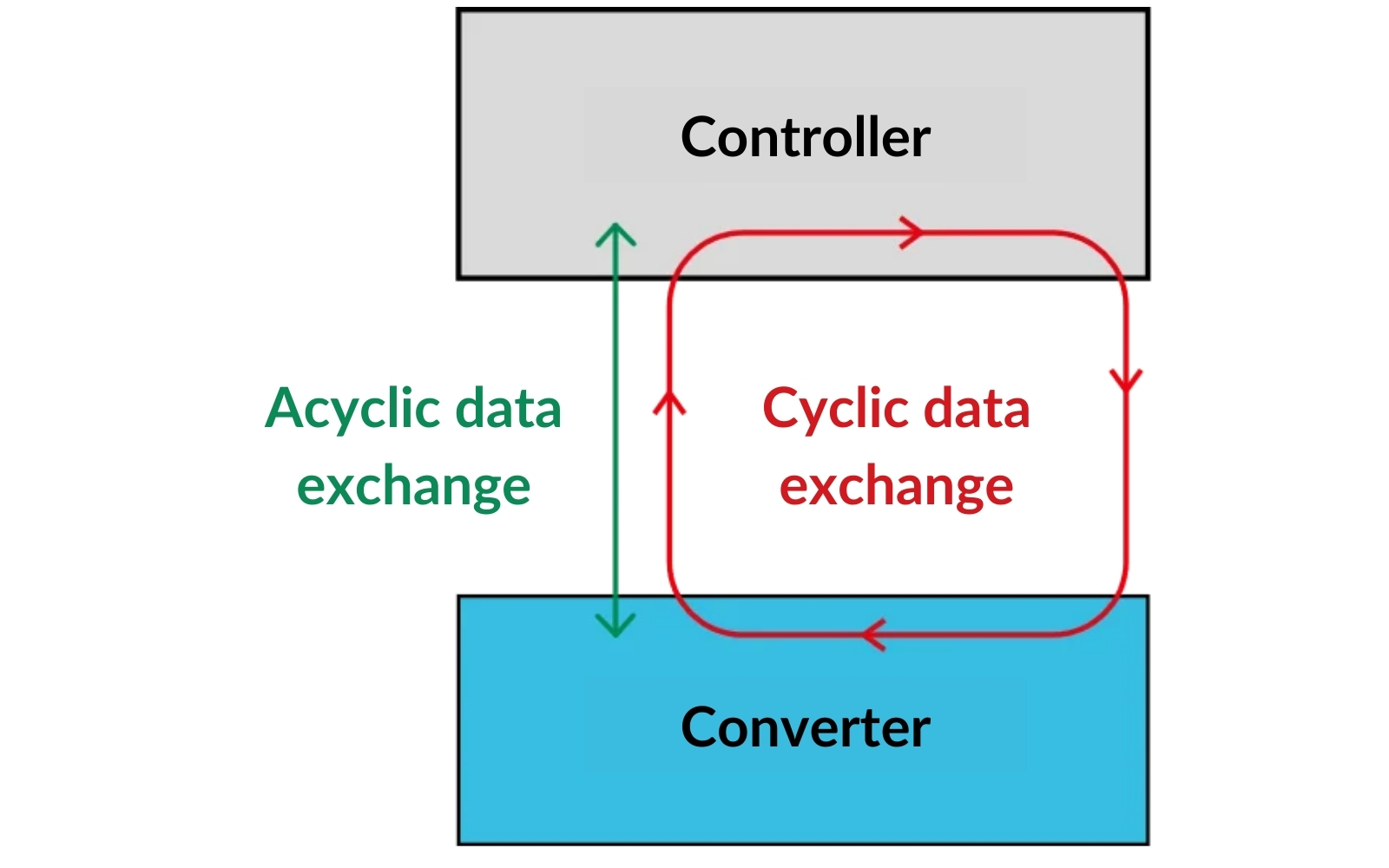

Cyclic data exchange involves sending control words and set values from the controller and receiving status words and actual values from the drive within a single program cycle.

Acyclic data exchange provides access to drive parameters (read/write) via engineering software or system library functions. This setup allows for the exchange of a large amount of information, even though it occurs over several program cycles. To summarize, the cyclic channel represents one cycle with a small amount of information, whereas the acyclic channel spans several cycles, enabling the transfer of a larger amount of information.

2.3 Isochronous Real-Time Mode (IRT)

We now understand the IRT mode. But what applications is it suitable for?

IRT mode primarily serves time-critical applications, where the program simultaneously calculates and collects data from various modules. Therefore, the system must deliver data in sync to ensure the program maintains up-to-date information required for each calculation cycle.

Examples of applications where IRT is recommended include:

- Position measurement systems on camshafts

- Plastic injection molding machines

- Packaging machines

- Printing presses

- Woodworking machines

2.4 Isochronous IRT Steps

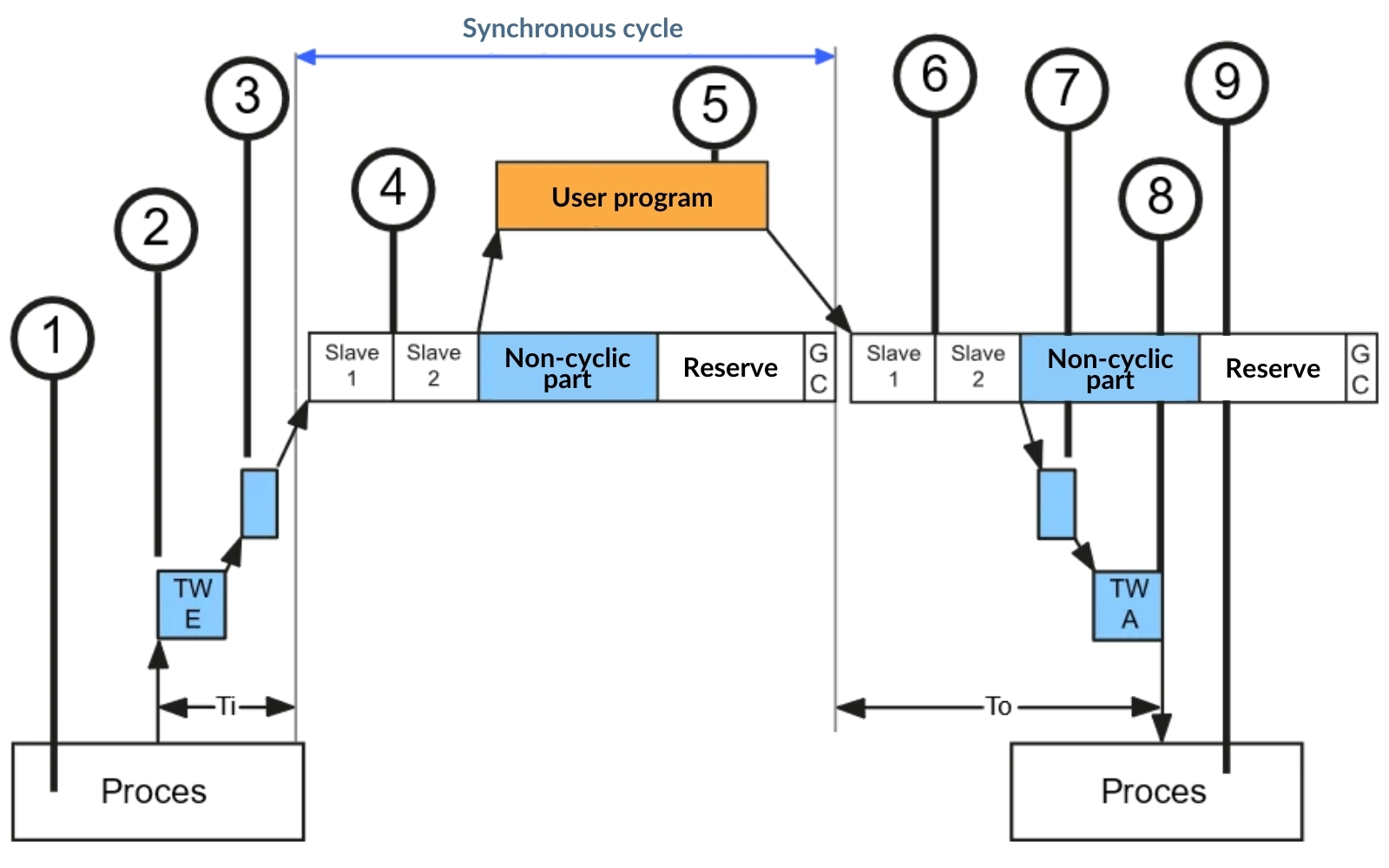

Below are the steps involved in IRT communication.

Steps explained:

- Transfer the signal value to the process

- Read measurement value from the process

- Convert measurement to digital form in the input module

- Transfer digital measurement from the input module to the interface module

- Send measurement to the CPU unit

- Process measurement in the synchronous OB block

- Send the processed measurement result to distributed modules

- Send output signal from the interface module to the output module

- Process the output value

3. Summary

In this post, we covered two topics concerning the PROFINET IO network. Now you know the differences between RT and IRT modes, when to use them, and what the PROFIdrive standard is.

While this topic may not be difficult, it is quite extensive. In our drive course, you can learn more about these topics from a practical perspective, focusing on drive programming.

Thank you for reading! If you’re interested in learning more, explore our courses for in-depth training: Control Byte Courses.