Powering a Circuit: Source vs Sink

In this article, we’ll explore sinking vs sourcing and what it means to power a circuit, focusing on how these concepts impact the connection and control of PLC systems.

Powering a Circuit

To power a circuit, you need three key elements: a voltage source, a load, and a ground. Sinking and sourcing describe two methods of providing power to a circuit.

Sourcing refers to supplying the voltage for the circuit, while sinking provides the necessary ground connection.

As discussed in the previous article Sinking and Sourcing PLC Outputs Explained, the main difference between sourcing and sinking lies in the direction of the current flow.

Determining the Source and Sink sensor

Let’s visualize two devices connected together. If current flows from Device 1 to Device 2, then Device 1 is acting as the source, and Device 2 is the sink.

If the current flows in the opposite direction, then Device 2 becomes the source, and Device 1 is the sink. The direction of current flow is important because it determines whether you are using a sourcing or sinking setup. However, the choice of components also depends on wiring configurations, terminal blocks, and the common inputs or outputs that may be shared.

Additionally, your PLC card will either be a sink or a source, and it must be wired correctly. This is something that design engineers must consider when specifying components for a system.

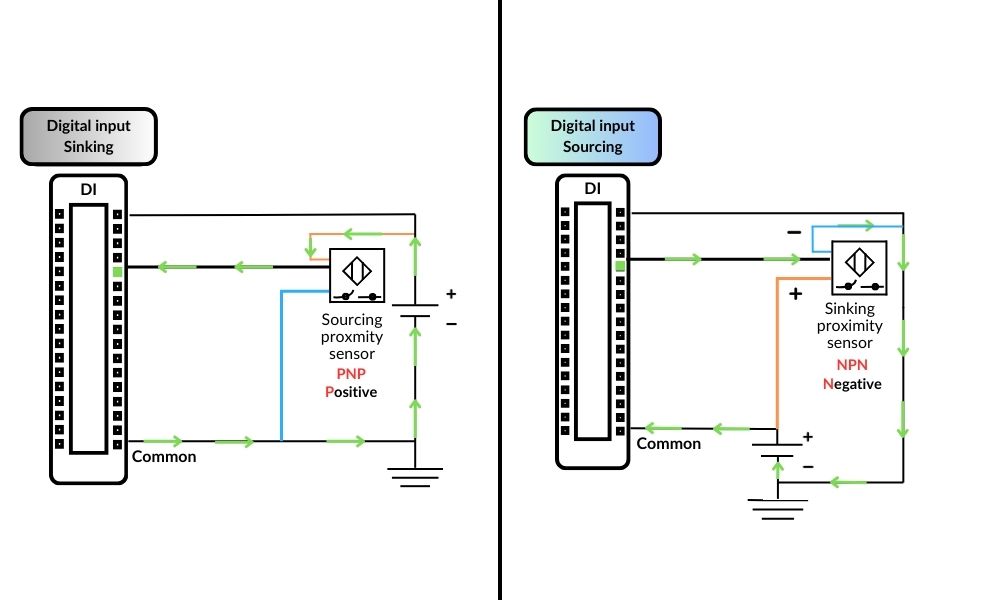

PLC Sinking Input / Output: Understanding Current Flow Paths

Sinking provides a path to the supply common. In this type of circuit, when the button is pressed and the contacts close, current flows from positive to negative into the PLC as an input. The common supply in this case is negative, making this a sinking configuration.

On the output side, a sinking output module allows current to flow into it from the load. This is achieved using NPN transistors for switching.

PLC Powering: Sourcing Input / Output

Sourcing, on the other hand, creates a path to the supply source. The key difference is in the positioning of the common and the button, but the input to the PLC remains positive.

With a sourcing output module, the current flows out of the module and into the load. This type of output uses PNP transistors for switching.

Key Design Considerations for PLC Inputs and Outputs

When wiring a circuit, it’s important to consider the requirements of the instruments being connected. Many devices use either PNP (positive) or NPN (negative) transistors, and the polarity of the current will dictate the power sourcing needed. Transistors, unlike relays, rely heavily on the correct polarity.

Many proximity switches available today are equipped with either PNP or NPN transistors, so the design needs to account for these configurations.

Good design practices involve wiring all input/output points with a shared common, either as a source or sink. This approach saves time, reduces the number of terminal blocks, and frees up space in the control cabinet.

Wiring Circuits Effectively

By wiring circuits in blocks, the common can be shared among multiple sensors, simplifying the design. Keep in mind that this discussion is focused on 3-wire sensor circuits and does not apply to AC-powered systems, where the polarity switches naturally. In DC systems, transistors handle the switching, so it’s crucial to avoid mixing AC power with a DC sourcing/sinking point to prevent faults.

It’s also worth mentioning that in many sinking circuits, the shared common is usually negative (-), although this isn’t necessarily a better practice—just a more frequent one.

Conclusion

Most modern PLCs allow for flexible wiring of NPN (sinking) or PNP (sourcing) inputs and outputs, though this often needs to be done in blocks with a shared common. Understanding the wiring scheme of your PLC is critical, especially when troubleshooting or adding new input/output cards.

In the design phase, careful planning will ensure that all components—whether cards, instruments, or commons—match the requirements of the application. Aligning the design with the system’s needs is more crucial than deciding whether sourcing (PNP) or sinking (NPN) is better.

In short, a well-thought-out wiring scheme ensures greater safety and cost-efficiency.

If you’re looking to learn more about PLCs, there are several helpful courses available, such as PLC Fundamentals for Control Systems and PLC Hardware Fundamentals.

Thank you for reading! If you’re interested in learning more, explore our courses for in-depth training: Control Byte Courses.