The Industrial Internet of Things (IIoT) has become the driving force behind a transformative revolution, reshaping industries by digitally connecting physical devices and machines. As this technology evolves, new opportunities arise to enhance efficiency, optimize processes, and improve product quality. This article aims to provide a detailed overview of IIoT devices and platforms, offering a comprehensive review of the technologies powering the fourth industrial revolution. Join us on a fascinating journey as we delve into the diverse range of IIoT devices and their impact on modern industry.

IIoT Devices (Industrial Internet of Things)

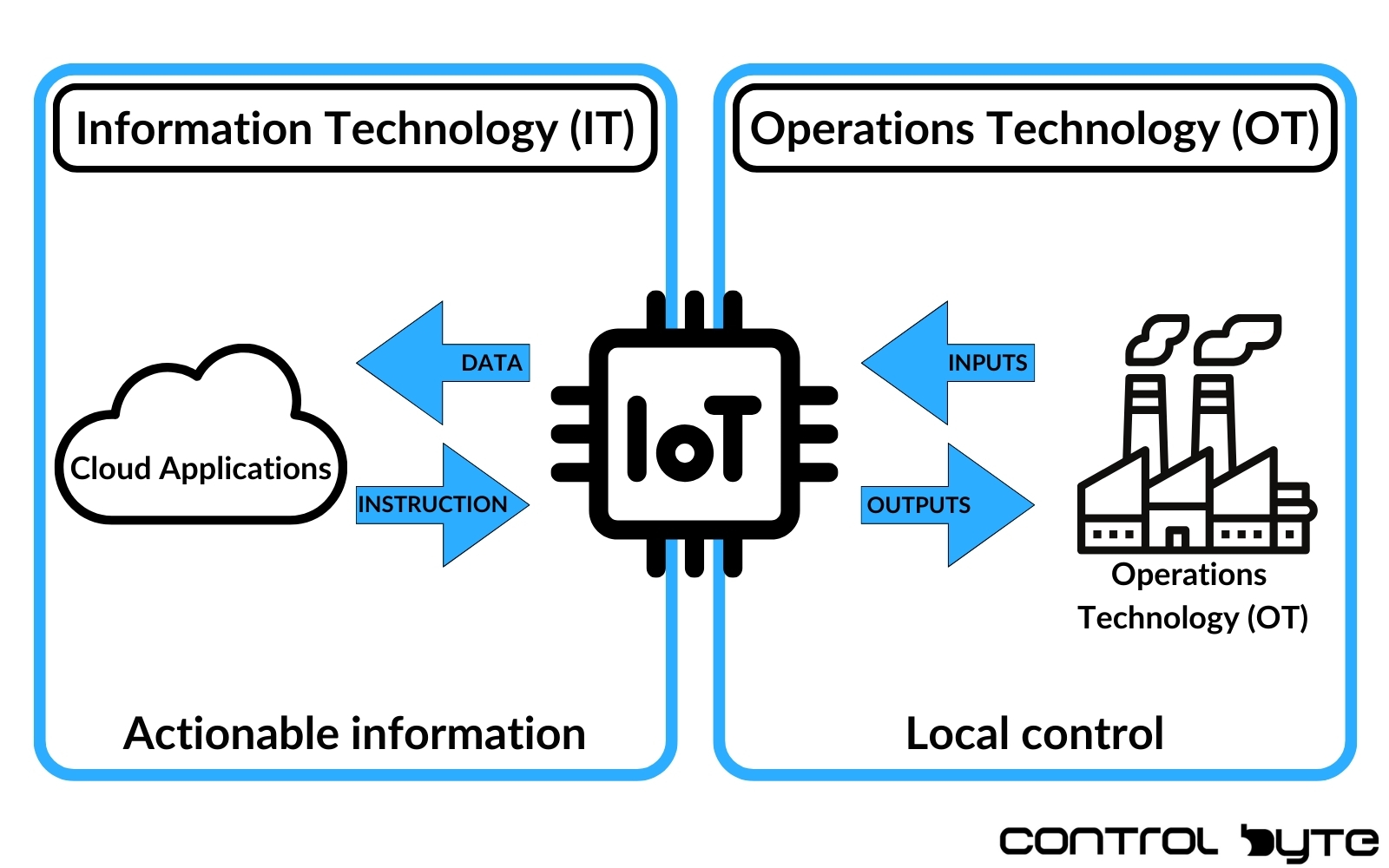

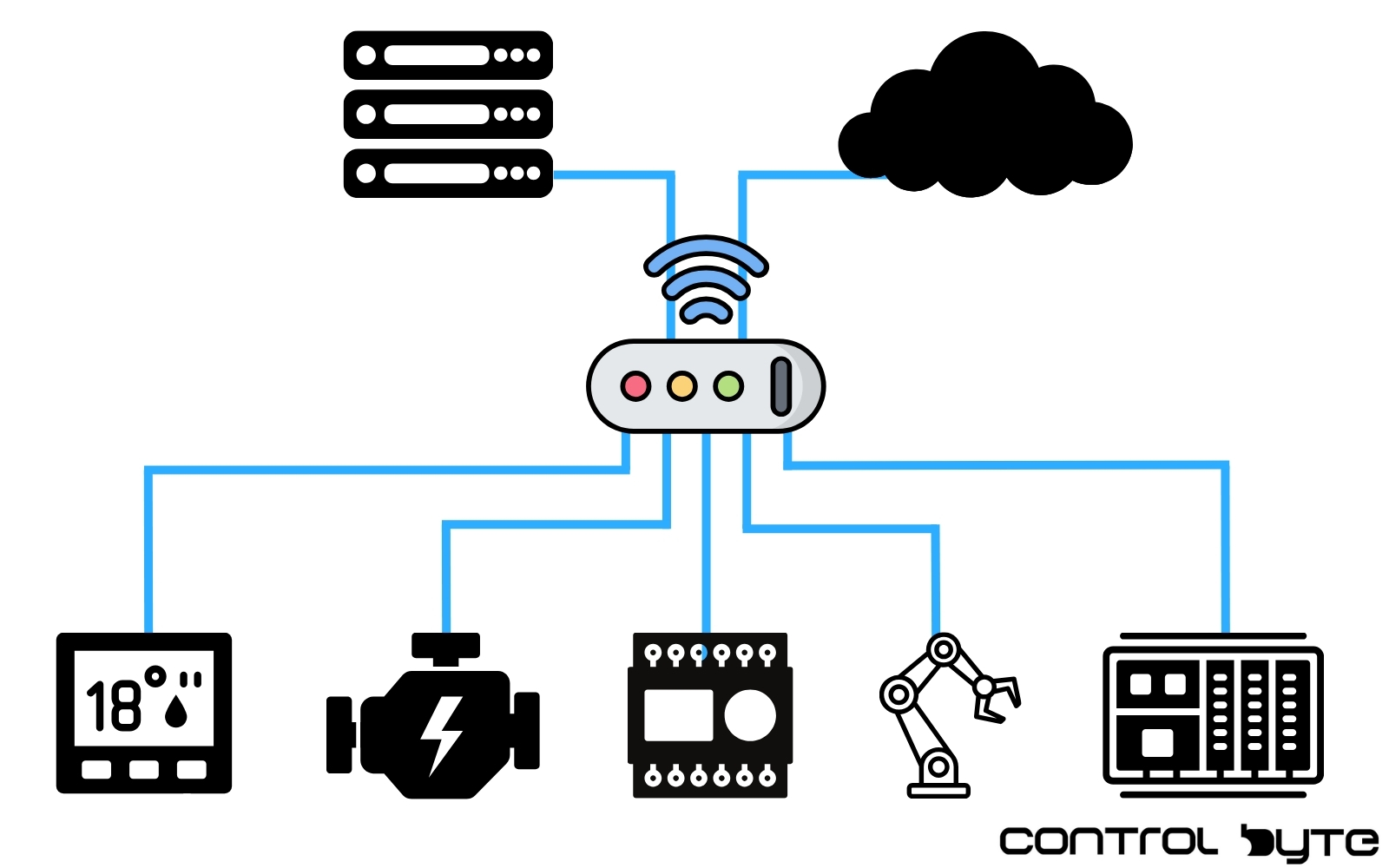

IIoT devices are key components of networks located at the “edge” of the network topology, often referred to as edge devices. From an IT infrastructure perspective, they serve as access points to automation networks, known as Operational Technology (OT) networks.

The primary purpose of IIoT devices is to facilitate data exchange between various IT and OT networks while avoiding mutual interference. They act as a bridge, enabling efficient information transfer between operational and technological environments.

IIoT devices are primarily used to share data and information from the automation environment with the IT environment. This enables companies to better analyze, monitor, and optimize production and operational processes, enhancing their competitiveness in the rapidly evolving industrial landscape.

Industrial iot Edge Devices

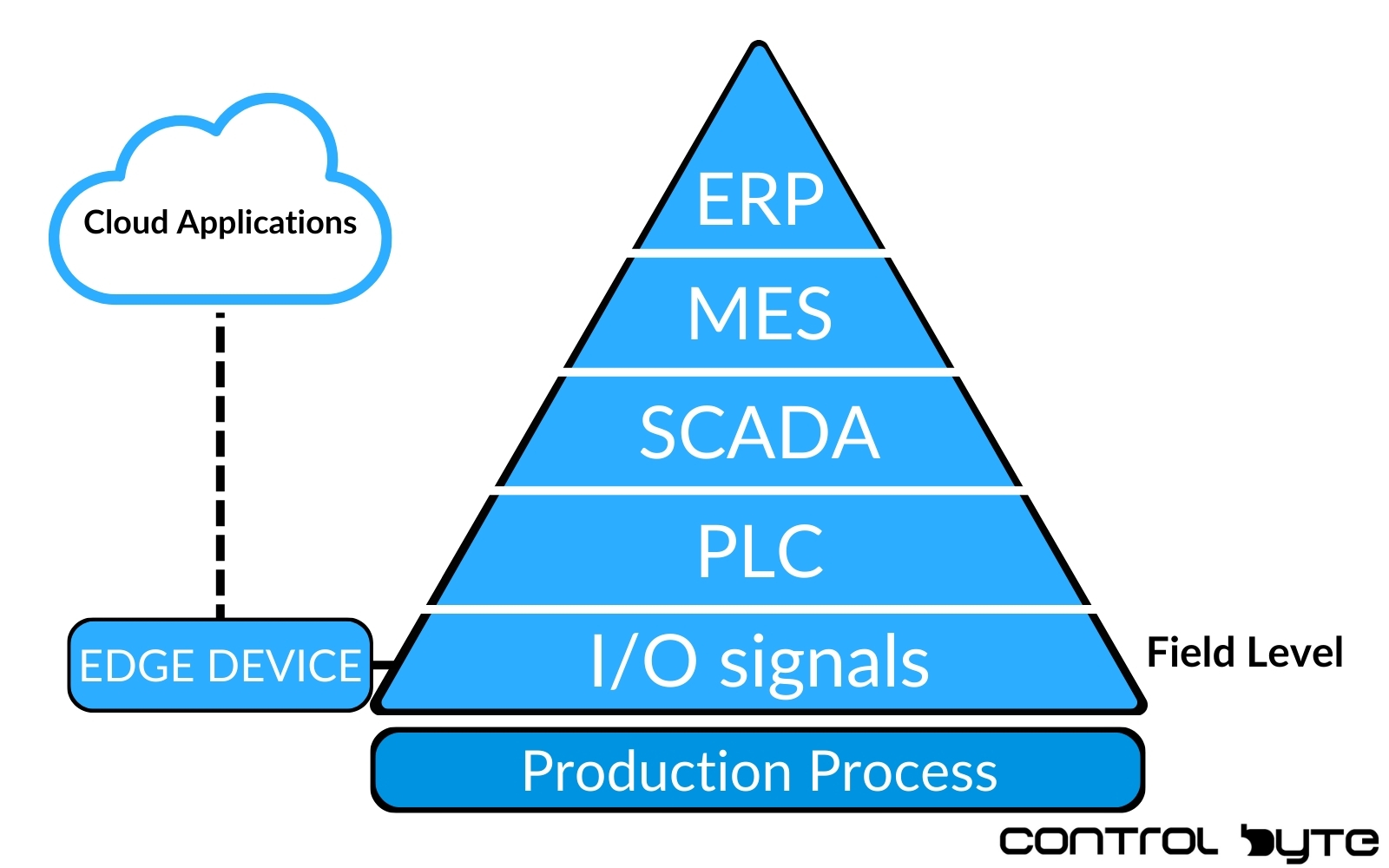

Edge devices are components installed near or directly at the location where data is generated within an industrial system. Their primary function is to transmit this data between the local network and the cloud. A key feature of these devices is protocol translation, which involves converting the “languages” used by local devices into protocols like MQTT or HTTP, commonly used in the cloud for further data processing.

In practice, edge devices act as a bridge connecting field devices with the cloud, enabling seamless communication and data exchange within the industrial system. As such, they have become an indispensable element of modern IIoT solutions.

Types of Edge Devices

Edge devices can be divided into two main types, which differ in terms of functionality and application:

Traditional Edge Devices are responsible for securely transmitting data within a network but generally lack significant data processing capabilities. Examples of such devices include:

- Edge Routers: These enable the sharing of a single internet connection among multiple devices. They connect different networks, manage traffic between them, and route data to specific IP addresses.

- Routing Switches: Multi-port devices that connect computers, printers, servers, and other devices within local (LAN) or wide area networks (WAN).

- Firewalls: These monitor incoming and outgoing network traffic, detecting and blocking potential threats such as malware.

Smart Edge Devices

Smart edge devices have the capability to perform computational tasks near the data source. This enables the automation of industrial processes and the integration of advanced IoT and IIoT systems. Examples of such devices include:

- Smart Sensors: Detect and correct abnormal physical conditions in the machine’s environment, ensuring its proper operation.

- Smart Actuators: Convert computer signals into physical actions, such as machine movements.

- IIoT Gateways: Connect multiple sensors and other devices to cloud platforms, enabling data analysis, processing, computation, and storage.

- M2M Devices (Machine-to-Machine Devices): Facilitate direct communication between machines, supporting automation and data transfer in industrial systems.

These two types of edge devices play a crucial role in IIoT ecosystems, supporting both the core network infrastructure and advanced analytical and operational capabilities.

What is Edge Computing?

Edge computing is a method of improving data aggregation and processing by placing computational resources in close proximity to the locations where data is collected. These resources can include machines, gateways, protocol converters, or other types of industrial controllers.

The philosophy of edge computing is based on the premise that processing information where it is generated is faster and more efficient. Consider the journey data takes from an industrial device to a data center. Traditional cloud-only approaches require transmitting data over long distances for processing, which can lead to issues related to latency, network bandwidth, and data management.

In high-sensitivity production processes, even slight delays in data processing can significantly impact efficiency and quality. Edge computing mitigates this issue by enabling data processing close to its geographical origin and within the same network where it is generated.

While the cloud remains indispensable for storing, analyzing, and processing large volumes of data, edge computing provides critical benefits in scenarios where rapid response times are crucial. The modern need for monitoring industrial machines makes edge computing an attractive solution. The greatest benefits can be achieved by combining cloud infrastructure with edge computing, depending on operational requirements. This approach allows manufacturers to maximize the impact of their digital initiatives, achieving both speed and precision alongside flexible data storage.

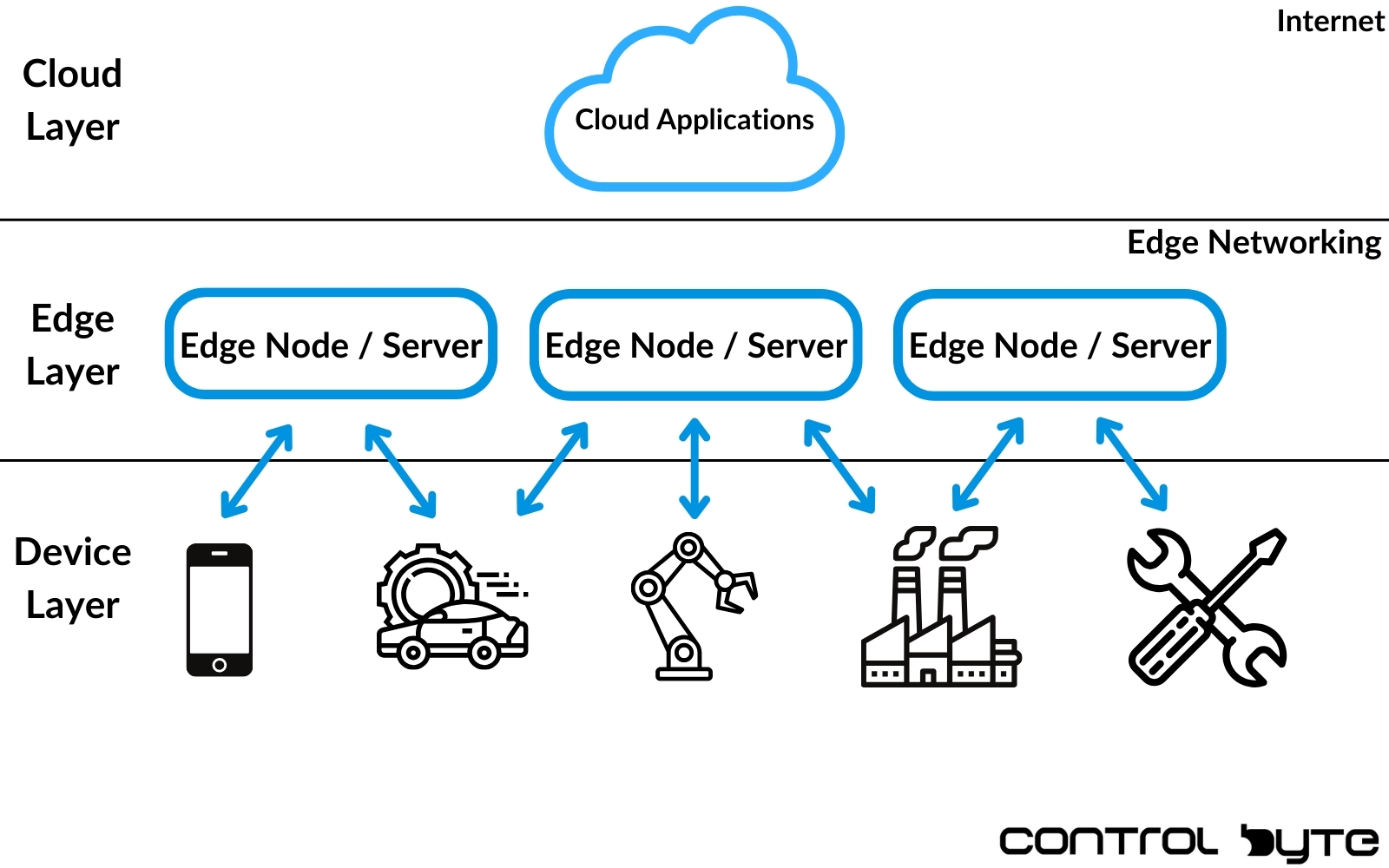

What is an IoT Gateway? (Industry 4.0 – Cloud)

An IIoT Gateway is a device that enables the connection and collection of data from various industrial machines and IoT devices. Once the data is gathered, the gateway transmits it to the cloud or data centers, where it can be processed, remotely monitored, controlled, and subjected to more detailed analysis.

In addition to data transmission, an IIoT gateway can manage connected IoT devices and ensure the security of the IoT network, protecting it from potential threats.

In short, an IIoT gateway acts as a bridge, connecting IoT devices to the cloud, enabling seamless data flow and the integration of IoT solutions into industrial systems.

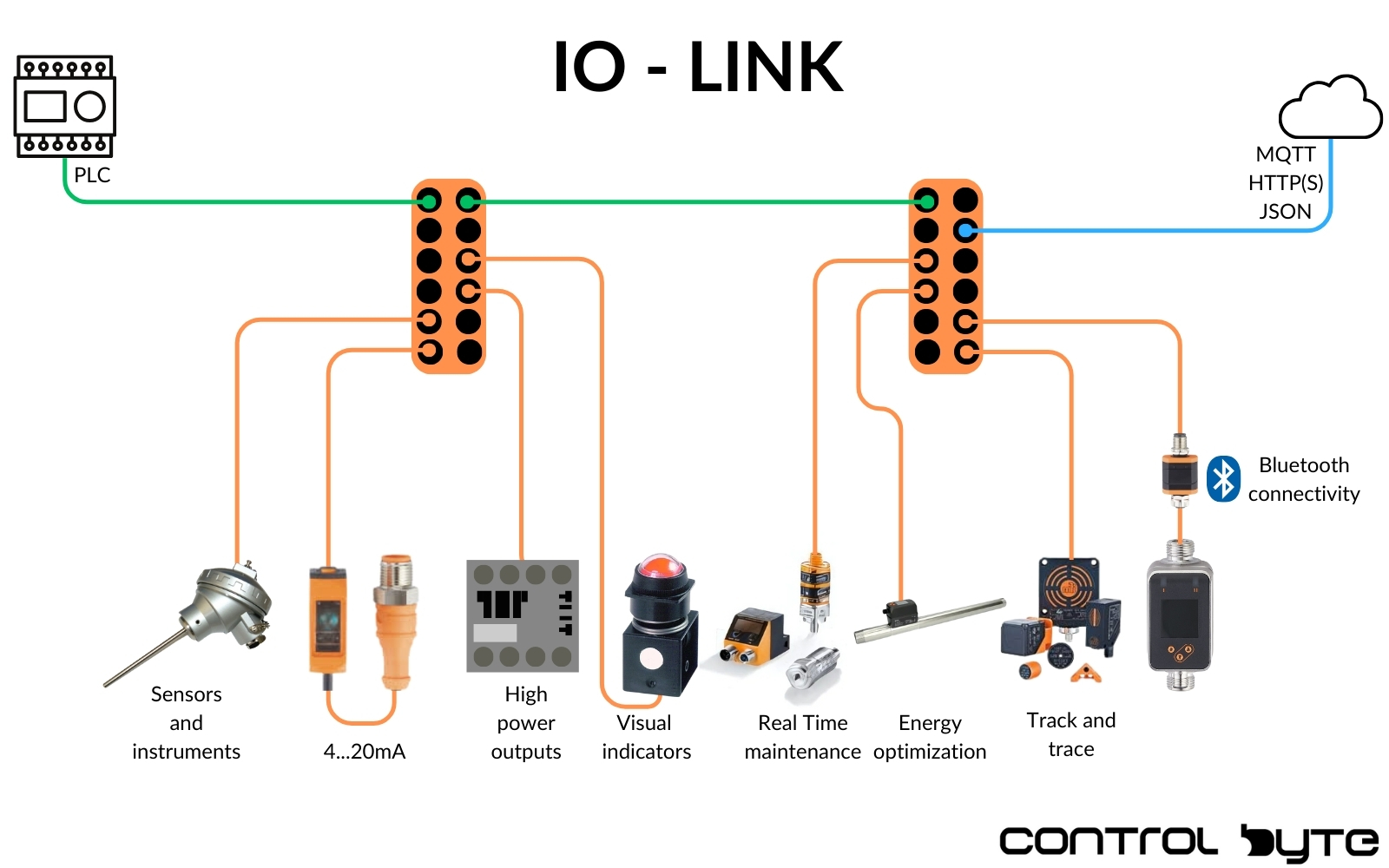

IO-Link Technology and Industry 4.0

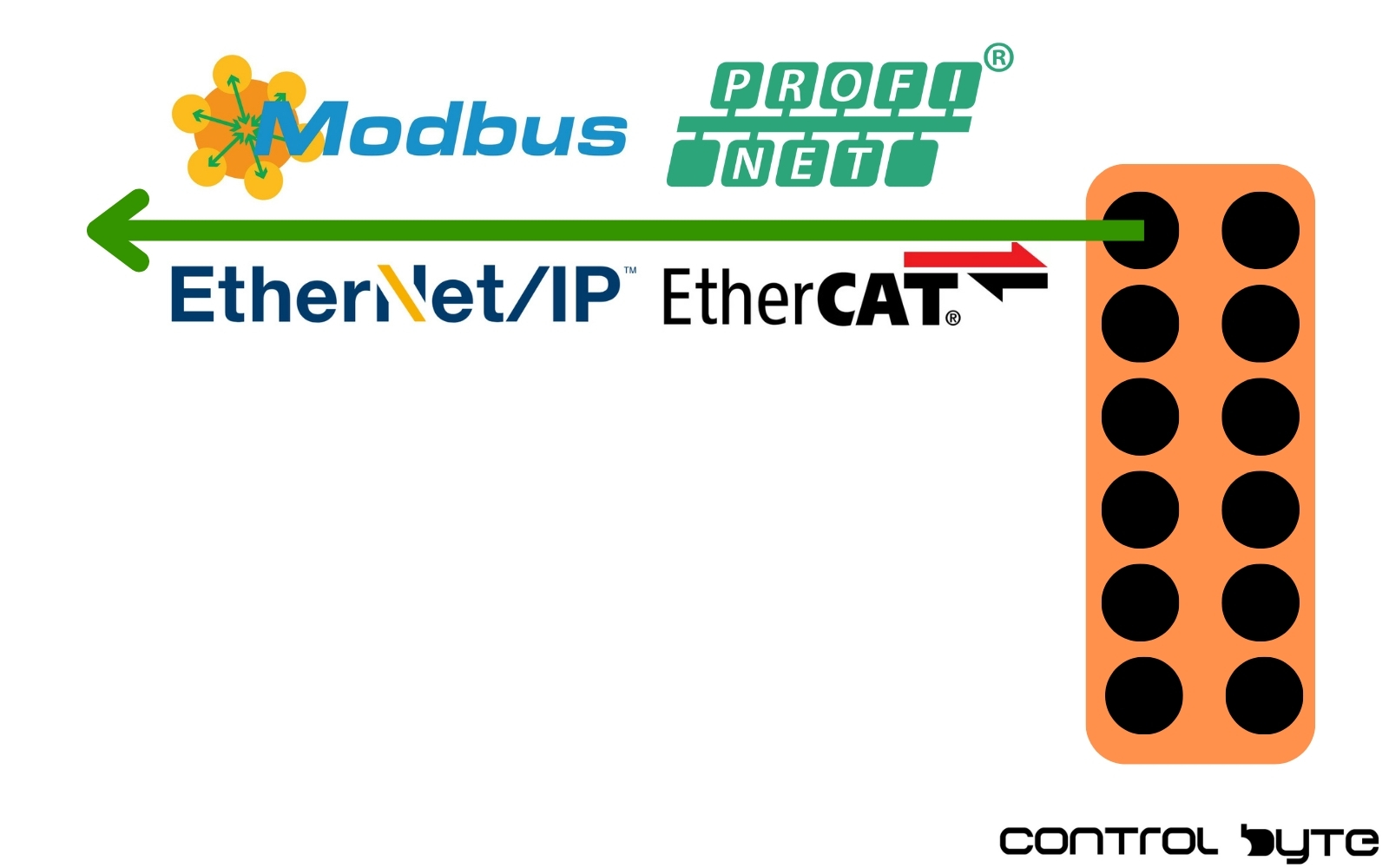

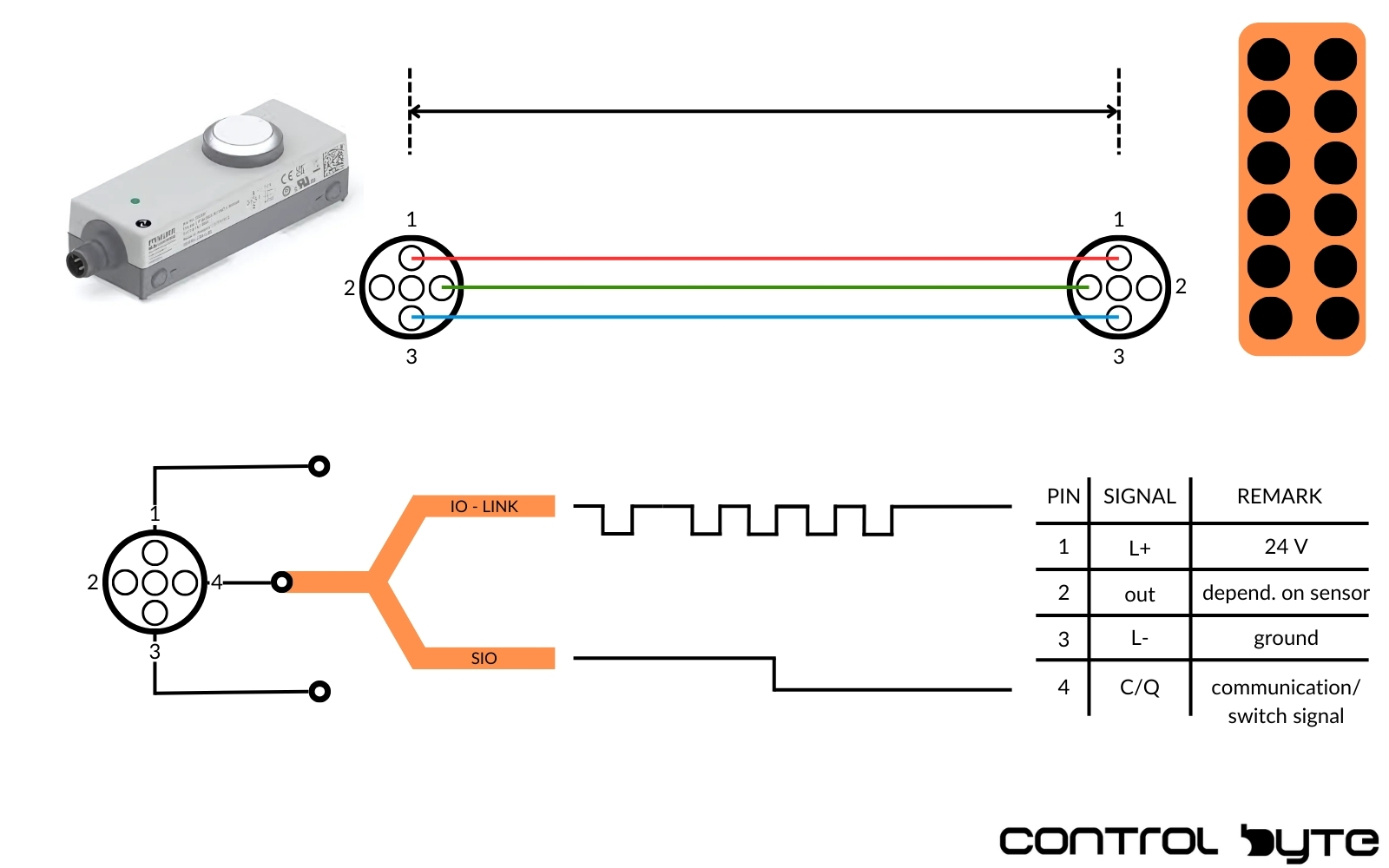

IO-Link (Input/Output Link) is a digital communication protocol used in industrial automation systems. This protocol allows devices such as sensors and actuators to communicate with automation systems in a more advanced and flexible way compared to traditional solutions.

To connect IO-Link devices to an automation system, an IO-Link Master is required, which acts as an intermediary between IO-Link devices and the higher-level control system. This enables seamless data transmission and reception, improving the precision and efficiency of production processes.

The IO-Link protocol also supports diagnostic and configuration functions, facilitating easier device management and quicker detection of potential issues in industrial systems. It is one of the key tools driving the concept of Industry 4.0.

The IO-Link Master replaces traditional analog input cards with a digital communication pathway between devices and the automation system. Depending on the configuration, a single IO-Link Master can connect up to 8 IO-Link devices, such as sensors, valves, or input/output modules.

The Master plays a critical role in system integration, transmitting machine data, process parameters, and diagnostic information to a PLC or directly to a higher-level IIoT management system. This enables efficient process monitoring and control, as well as easier diagnostics and maintenance of devices.

The IO-Link Master enhances the flexibility and functionality of automation systems, supporting the digital transformation of industry and the implementation of advanced Industry 4.0 technologies.

The Role of the IO-Link Master

The IO-Link Master acts as an intermediary between IO-Link devices and the automation system, managing bidirectional information exchange. It receives data from IO-Link devices, such as sensors or actuators, and transmits commands or queries to them, ensuring smooth and efficient communication.

The IO-Link Master can be installed in a control cabinet or in the field as a remote I/O module, depending on the requirements of the specific automation configuration. This flexibility allows adaptation to a wide range of industrial environments and applications.

Furthermore, the IO-Link Master supports both digital signals and analog values, enabling seamless integration with existing systems. This makes IO-Link technology a key component in modernizing industrial automation infrastructure and advancing its digitization.

Summary

The Industrial Internet of Things (IIoT), along with technologies like edge computing, IIoT gateways, and the IO-Link protocol, is revolutionizing modern industrial automation. Advanced edge devices, which process data close to its source, enable companies to minimize latency, enhance efficiency, and achieve greater control over their processes.

IIoT gateways act as a bridge between field devices and the cloud, facilitating secure and efficient data collection, transmission, and analysis. Meanwhile, IO-Link, supported by IO-Link Masters, introduces a new communication standard that not only connects devices but also integrates digital and analog signals into automation systems.

These technologies collectively support the vision of Industry 4.0, enabling more flexible, precise, and advanced management of industrial processes. By harnessing their potential, businesses can achieve their goals more effectively, accelerate digital transformation, and gain a competitive edge in the market.

If you found our article interesting, we encourage you to explore our range of online courses: https://www.controlbyte.tech/