Siemens S7-1200, S7-1500 PLC in LAD/FBD

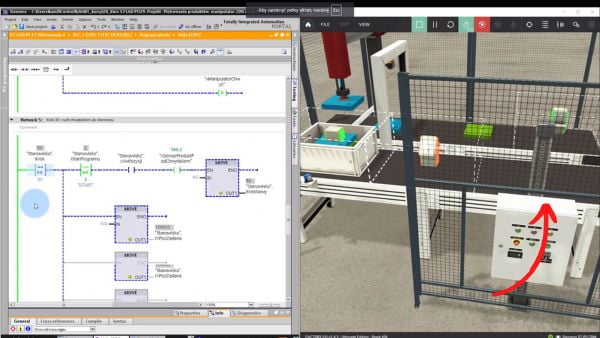

You will program PLC in virtual factory, check out what you will learn!

Video lessons

106

Duration

+18 hours

Skill Level

Beginner – Intermediate

Students

1645

Rating

4.92/5

Certificate Issued By

ControlByte

Trusted by Industry Leaders to Train Their Teams

What will you learn?

-

Siemens TIA Portal: Installation, licensing, setup, and integration with Factory IO.

-

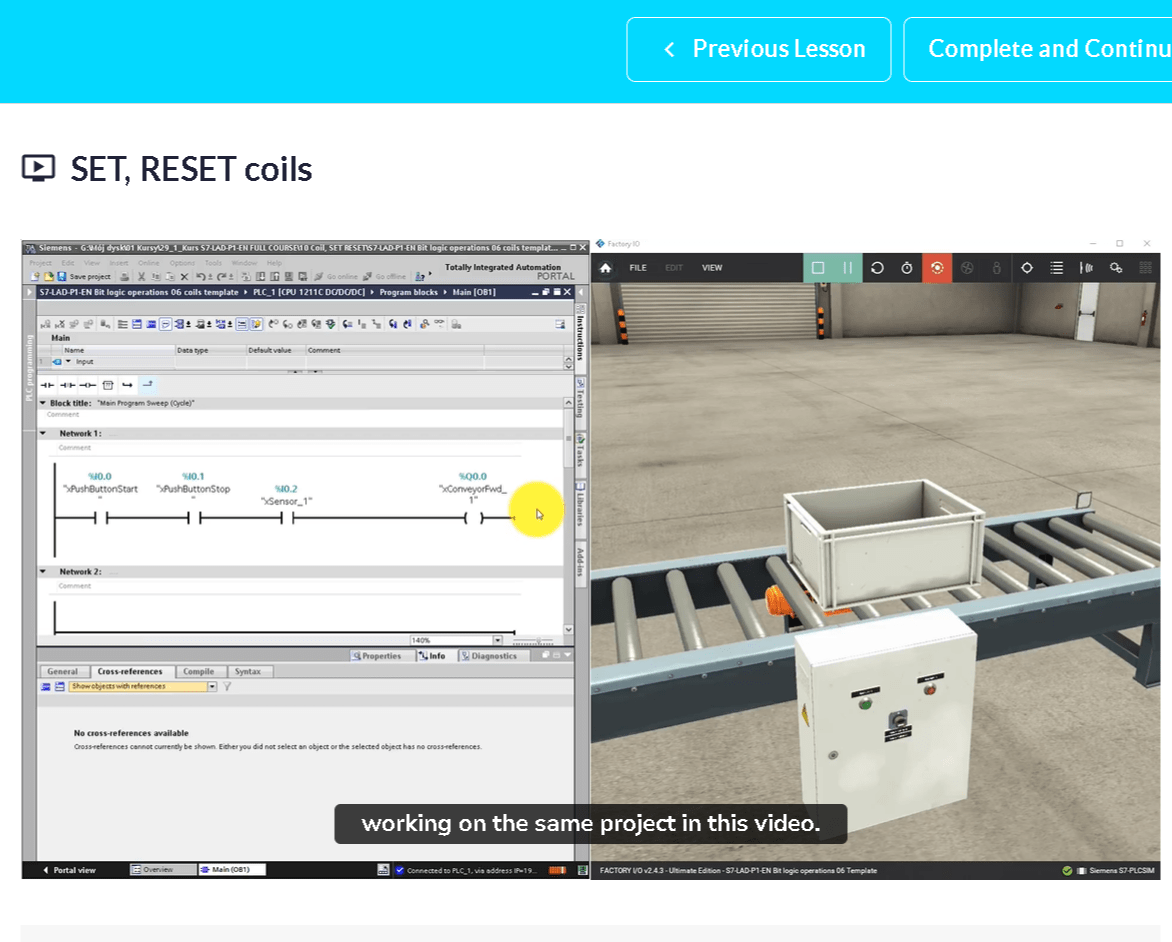

PLC Programming: Master core instructions (SET/RESET, timers, counters) and data operations.

-

Structured Programming: Use OB, FB, FC, and advanced data types (arrays, structures).

-

Mathematical Operations: Perform calculations and type conversions (integers, floats).

-

PID Control Project: Design a water level controller with precise PID regulation.

-

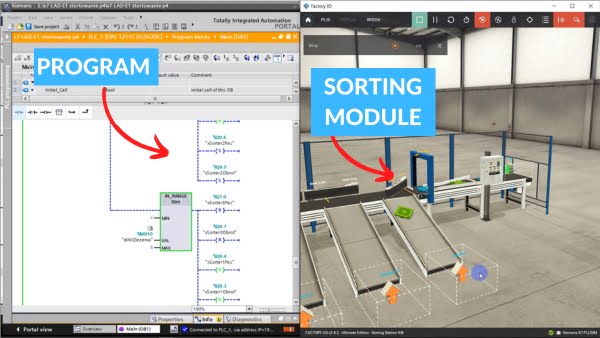

Vision System Integration: Develop a color-based sorting system with conveyors and sensors.

-

Factory Simulation: Build a complete simulation with advanced data handling.

-

Pallet Distribution Project: Program pallet measurement and distribution using timers and counters.

-

2D Manipulator Project: Create a system for stacking products with structured programming.

Join now for 400€ 249€

📖 Join the current group of students and start learning today!

What makes the ControlByte PLC courses so popular?

-

You get access to video lessons on the e-learning platform.

-

You perform programming exercises based on provided project templates. All you need is your PC and a simulator!

-

You can take the training whenever and wherever you want. You can start the training at a later date.

-

You will have homework assignments to complete on your own!

-

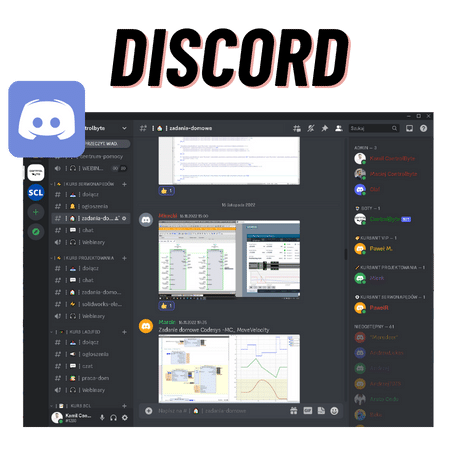

You receive course support through Discord chat and live meetings.

Course outline

106 lessons, 18 hours 22 minutes

Module 1: Introduction (2 lessons - 2:34) - FREE LESSONS

How to get help? Join the Discord group for Automation Professionals and PLC Programmers!

1:42

Module 2: TIA Portal and Factory IO Installation (4 lessons - 41:16) - FREE LESSONS

Siemens TIA Portal Installation

5:47

Create First Project in Siemens TIA Portal

10:19

Add HMI panel to your project

9:04

Module 3: Introduction to variables and memory areas (2 lessons - 22:11)

Variables types – introduction (analog value 0-10V in Factory IO)

11:53

Memory areas – Inputs, Outputs, M

10:18

Module 4: Introduction to Bit Operation Library in TIA Portal and variable types (3 lessons - 36:16)

Normally open contact -| |- AND operation (conveyor, switch, and sensor in FIO)

13:29

Normally open contact -|/| OR operation (add selector switch in FIO scene)

8:00

Normally closed contact -|/|- (diffuse sensor introduction)

14:47

Module 5: Exercises with bit logic operations (2 lessons - 17:34)

Start/stop button function – code with loop back

12:00

Homework

5:34

Module 6: Assignment instruction, SET RESET coils (4 lessons - 42:17) - FREE LESSONS

SET, RESET coils

12:18

Assignment instruction (coil) – using tips

10:51

Why hardware NC signals?

4:33

Module 7: Edge detection instructions – triggers (2 lessons - 23:51)

SIM Table – how to simulate signals?

2:24

Edge detection instructions

21:27

Module 8: FBD logic instructions (3 lessons - 13:53)

FBD logic instructions – theory

5:18

FBD logic instructions – example + homework

7:53

FBD logic instructions – homework – solution

0:52

Module 9: Timing Instructions (5 lessons - 36:23) - FREE LESSONS

TP timer

7:03

TOF timer

8:24

TONR timer

8:00

TONR timer

6:00

Module 10: Counters (5 lessons - 39:24)

Counters 1 – CTU

14:25

Counters 2 – CTU homework

5:13

Counters 3 – CTD

4:49

Counters 4 – CTUD

6:47

Counters 5 – CTUD homework

8:10

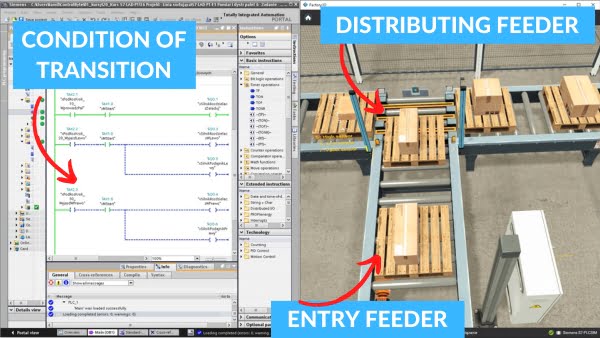

Module 11: Project – Pallet measurement and distribution (9 lessons - 1:25:38) - FREE LESSONS

Variable mapping

14:00

Systems testing

11:00

Starting system

7:21

Sequence programming – part 1

19:48

Sequence programming – part 2

13:06

Analysis of line operation

9:56

Homework assignment

6:46

Module 12: Comparison operators (3 lessons - 15:45)

Theoretical introduction

3:35

Comparator instructions

7:14

IN_RANGE, OUT_RANGE instructions

4:56

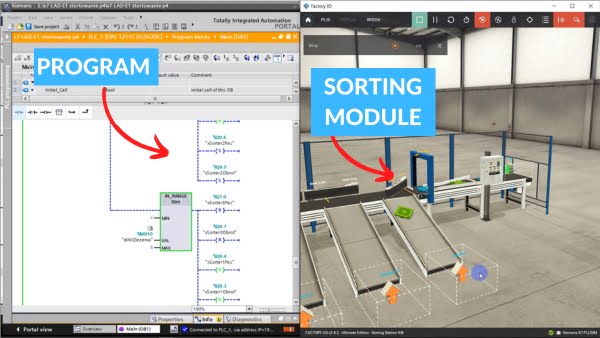

Module 13: Sorting line by color with vision sensor (5 lessons - 23:57) - FREE LESSONS

Sequence design for feeders

4:42

Sequence program for the input conveyor

6:26

Sequence program for the sorting conveyor

3:14

Sorting line homework assignment

4:57

Module 14: Mathematical instructions (8 lessons - 1:14:06)

Math – intro

1:37

ADD (ENO enable – check if result’s correct)

10:39

SUB, DIV, MUL instructions

12:38

MOD instruction

9:20

Calculate instruction

11:00

INC, DEC instruction

12:00

MIN, MAX, LIMIT instruction

9:36

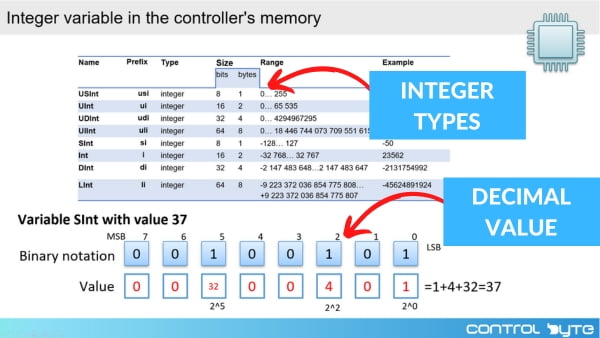

Module 15: Operations on integers (4 lessons - 47:12)

Introduction, integer variable in controller’s memory

13:20

Integers – negative numbers

7:32

Error of exceeding variable range

9:39

Type conversion for integers

17:01

Module 16: Operations on floating-point numbers (3 lessons - 45:40)

Introduction to floating-point numbers

21:03

Arithmetics of floating-point numbers

11:01

Special cases of floating-point numbers – NaN, Inf+, Inf-

13:06

Module 17: Instructions for converting floating-point numbers (1 lesson - 21:35)

Instructions for converting floating-point numbers

21:35

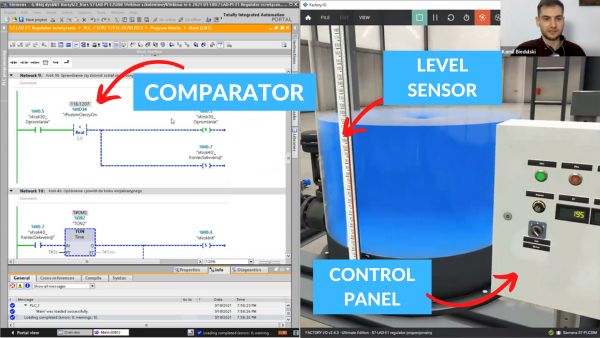

Module 18: Project: Proportional controller for a water tank (6 lessons - 1:09:20) - FREE LESSONS

Signals scaling

15:22

Regulator programming

16:44

Testing gain factors for P regulator

18:00

Sequential operation of the tank – homework assignment

4:00

Module 19: Operations on Words and Bytes (6 lessons - 1:36:59)

Operations on Words and Bytes – intro

14:38

Slice access

10:16

AND operation on bytes and words

14:40

OR, XOR operations on bytes and words

9:35

INV, DECO, ENCO

15:24

SEL, MUX, DEMUX

17:55

Module 20: Complex data types – arrays, structures (2 lessons - 34:32)

Arrays

19:24

Structures – STRUCT, UDT

15:08

Module 21: Program blocks, structural programming (6 lessons - 1:26:51) - FREE LESSONS

Structural programming – Introduction

4:53

OB organization blocks

10:50

FC functions

18:45

FB function blocks – part 1

21:54

FB – function block – homework

5:34

Module 22: Program flow control instructions (2 lessons - 0:00)

JUMP and LABEL instruction

0:00

JUMP_LIST and SWITCH instruction

0:00

Module 23: Project: Product stacking with 2D manipulator (10 lessons - 2:31:15) - FREE LESSONS

Project template and variable mapping

18:26

Position calculation, position flags

17:04

Starting system

13:14

Input and output conveyor

10:37

Manipulator sequence

20:28

Homing

13:30

Product database and search function

27:43

Product tracking with vision sensor

16:07

“In this course, you will learn to program PLC controllers, even if you are new to the automation industry.

All you need is a well-prepared learning path.”

Jacob K. Biedulski

-

Education: MSc. Automation and Robotics

-

Experience: 10 years

-

PLC projects completed: 80+

-

Students taught: 850+ in the past 3 years.

What will you receive after signing up for this PREMIUM course?

-

Over 106 practical video lessons (more than 18 hours).

-

You will test your programs in the virtual factory, Factory IO.

-

Support from instructors on Discord chat and live meetings.

-

You will have homework assignments to complete on your own!

-

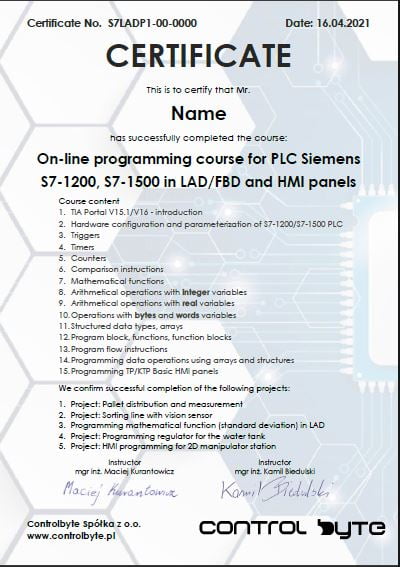

Certificate of course completion.

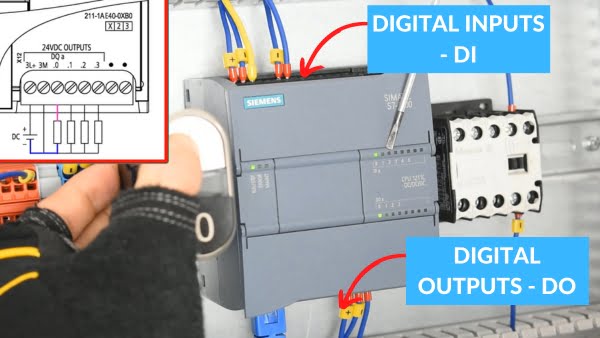

PLC Hardware

Module content:

-

Controller mounting in the cabinet

-

PLC terminals and interfaces

-

Connection

-

CPU configuration

-

Analog input configuration

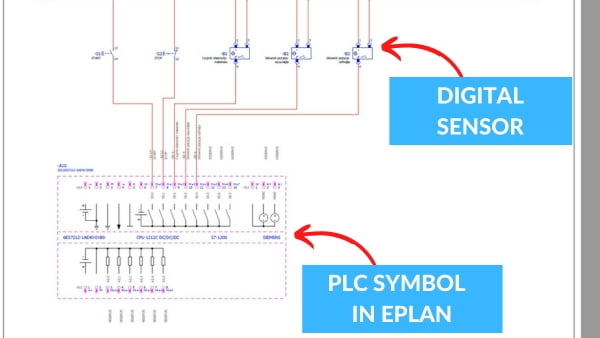

PLC on the electrical schematic

Module content:

-

Analysis of PLC controller documentation

-

What does a PLC schematic look like in Eplan

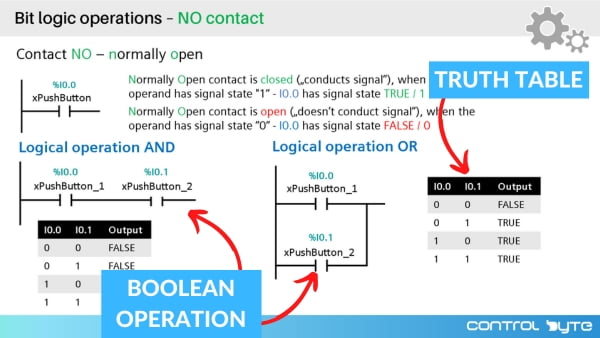

Bit instructions

Module content:

-

Normally Open (NO), Normally Closed (NC) contacts and Coils

-

SR (Set-Reset) and RS (Reset-Set) Flip-Flops

-

Boolean Algebra

-

Latching and Unlatching circuits

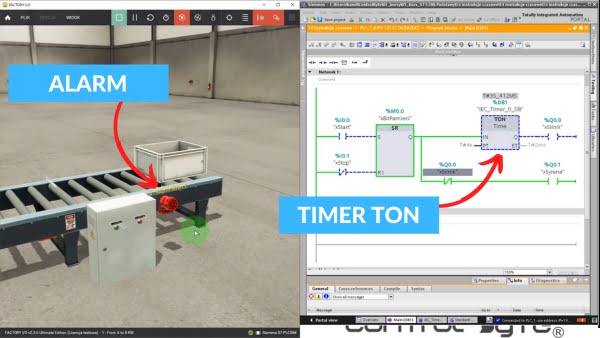

Timers

Module content:

-

TON Timer (Timer ON Delay)

-

TOF Timer (Timer OFF Delay)

-

TONR Timer (Retentive Timer ON) – task: line control

-

Implementing Pulse Timers (TP)

-

Practical applications of timers in industrial automation

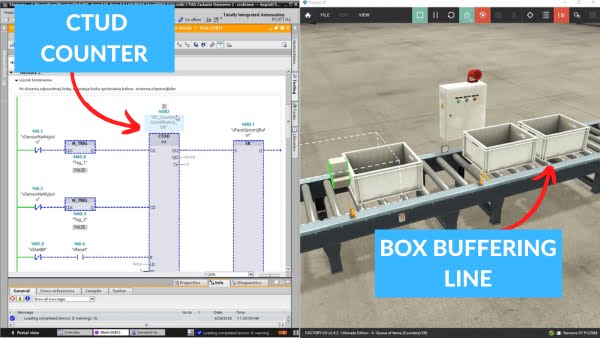

Counters

Module content:

-

CTU Counter (Count Up) – task: buffering package line

-

CTD Counter (Count Down)

-

CTUD Counter (Up-Down Counter) – task: sequential operation of buffering line

-

Counter reset (R) and counter preset (PV) functions

-

Practical applications of counters in industrial automation

Pallet sorting line based on product height

Module content:

-

Division of the workstation into cooperating objects

-

Programming of the separating feeder sequence

-

Programming of the input feeder

-

Homework assignment

Sorting by color

Module content:

-

Comparators

-

Sorting station in Factory IO

-

Operations on integers

Operations on INT and REAL variables

Module content:

-

Operations on integer numbers INT, DINT, SINT, USINT

-

Operations on floating-point numbers REAL, LREAL

-

Type conversion during calculations

-

Most common errors

Programming regulator for a water tank

Module content:

-

Converting values from level sensors and setpoints

-

Programming a controller for a liquid tank in Factory IO

-

Homework assignment

Programming 2-axis manipulator

Module content:

-

Programming sequence for 2-D manipulator

-

Logging data on currently transferred products

-

Programming a production order

Why you should join this course?

-

You gain a skill highly valued by employers.

-

You can showcase your certificate on LinkedIn, Goldenline, and of course on your CV!

-

If you want to change your job and pursue a career as an automation engineer, you are in the right place!

-

Hundreds of students have already taken this learning path, ask around what they say about us in the industry!

-

You get lifelong access to the course materials on our platform. You can revisit them whenever you want.

-

You will test all your written code in a virtual factory in Factory IO.

-

You do not need any equipment for the course. A PLC simulator and Factory IO are enough. The code you write can be used in real-life projects.

-

Hundreds of students have already taken this learning path, ask around what they say about us in the industry!

-

You receive course support through Discord chat and live meetings.

-

We will provide you with your code reviews by Discord channel!

-

You can chat with other aspiring PLC programmers!

Receive your certificate and publish it on LinkedIn!

-

You gain a skill valued by employers. You can publish the certificate on LinkedIn, Goldenline, and of course in your CV!

-

If you want to change jobs and take a position as an automation engineer in a company, you are in the right place!

-

You get lifetime access to materials on our platform. You can return to them whenever you want.

-

This learning path has already been tested by hundreds of students in the industry!

What industry experts are saying about us

Dobot Robotics

Automa.Net

Training price

Before I show you the price, see what exactly you get by joining the automation design course:

Educational materials, 106 video lessons explaining PLC programming concepts in LAD/FBD language. Through video materials, we will guide you step by step from simple topics to advanced projects.

Value: 200€

Value: 200€

Homeworks – you will have to be creative! Not everything in the course will be shown directly! You will have to come up with some solutions on your own.

Value: 50€

Value: 50€

Analysis of your homework – feedback from the teachers We check your homework and send comments to make your programs better and better!

Value: 100€

Value: 100€

Contact with instructors via the e-learning platform. If you have any problems, feel free to reach out! We will address your doubts on an ongoing basis.

Value: 100€

Value: 100€

Consultations in the form of weekly live webinars. You will be able to ask questions and participate in live discussions.

Value: 50€

Value: 50€

You will join the community of PLC programmers and be able to share your thoughts.

Solving problems through group work is much faster!

Solving problems through group work is much faster!

Value: PRICELESS

We guarantee that you will be satisfied with your participation in our course.

If you don’t like our training, you have 14 days to return the product – we will refund the full amount for the course.

If you don’t like our training, you have 14 days to return the product – we will refund the full amount for the course.

Value: PRICELESS

Hundreds of automation specialists have already completed our training program in previous editions.

Value: PRICELESS

Thanks to the proven formula of our training and cost optimization, you can purchase this training for:

249€

📚 Join the current group of students and start PLC programming today!

Join now for 249€

Safe transaction and 14-day money back guarantee!

-

Secure Transactions: we assure that your transactions are safe and secure.

-

Trusted Payment Gateways: We partner with trusted payment gateways for a seamless payment experience – powered by Stripe and PayPal

-

14-Day Money Back Guarantee: Enjoy peace of mind with our 14-day money back guarantee.

-

Risk-Free Enrollment: Enroll with no risk and explore the course before making a commitment.

-

Customer Satisfaction: We prioritize your satisfaction and are here to support you.

-

Transparent Refund Process: Our refund process is simple and transparent.

-

Invest with Confidence: Secure your future with confidence in our PLC course.

Opinions from Students

Watch the video and see the training path completed by over 2000 programmers!

FAQ

How can I sign up for the course?

Use the “Join the Course” button on this website or send us an inquiry at: contact@controlbyte.tech

Will I receive support from the instructors for this training?

Yes! We stay in touch with you through Discord channel – chat for participants, forums, and live meetings – webinars.

Will I receive a certificate upon completion of the training?

After submitting all projects from homework assignments and having them checked by the instructors, you will receive a certificate of completion for the training.

Will I need a PLC controller during the course?

No! In the course you will use advanced PLC simulator, so you won’t need a real PLC controller. The Factory I/O environment simulates automation systems such as conveyors, manipulators, actuators, robots, etc. The PLC controller’s operation is simulated using the Siemens S7-PLCSIM environment.

Do I need to purchase a license for Siemens TIA Portal software?

No! You only need a free license.

What if it turns out that the course is not for me? Can I return the course?

You have 14 days to return the course, counting from the start date of the course. We guarantee a safe purchase.

Do I need to purchase a license for Factory I/O software?

No! To participate in the course, a free license is sufficient.

Is the course suitable for me if I have no prior experience with programming?

Yes. This is a basic course, designed in such a way that even someone without any experience with PLC controllers will be able to learn programming in LAD/FBD language.

How long will I have access to this course?

Access to the course is lifetime! As long as the ControlByte company exists in the automation market.

What does an online course on the ControlByte platform look like?

You get access to video materials with lessons explaining programming concepts. Participants follow exercises according to guidelines from the videos.

They also have homework assignments to solve independently. Homework projects are uploaded to the portal, where instructors check the tasks and provide feedback.

I would like to purchase training for my company. I need an official offer.

Please send an email with the information needed for the offer. We will send the offer to the indicated address. Upon receiving the order, we will grant you access to the course. Payment can be made according to the agreed commercial terms.

contact@controlbyte.tech

Can I receive an invoice?

No problem, please send us an email.

contact@controlbyte.tech

What if I have a problem or something is unclear?

Send us e-mail: contact@controlbyte.tech

Siemens PLC Training

WITH A 14-DAY MONEY-BACK GUARANTEE

PRICE:

249 €

📖 Join the current group of students and start learning today!